Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

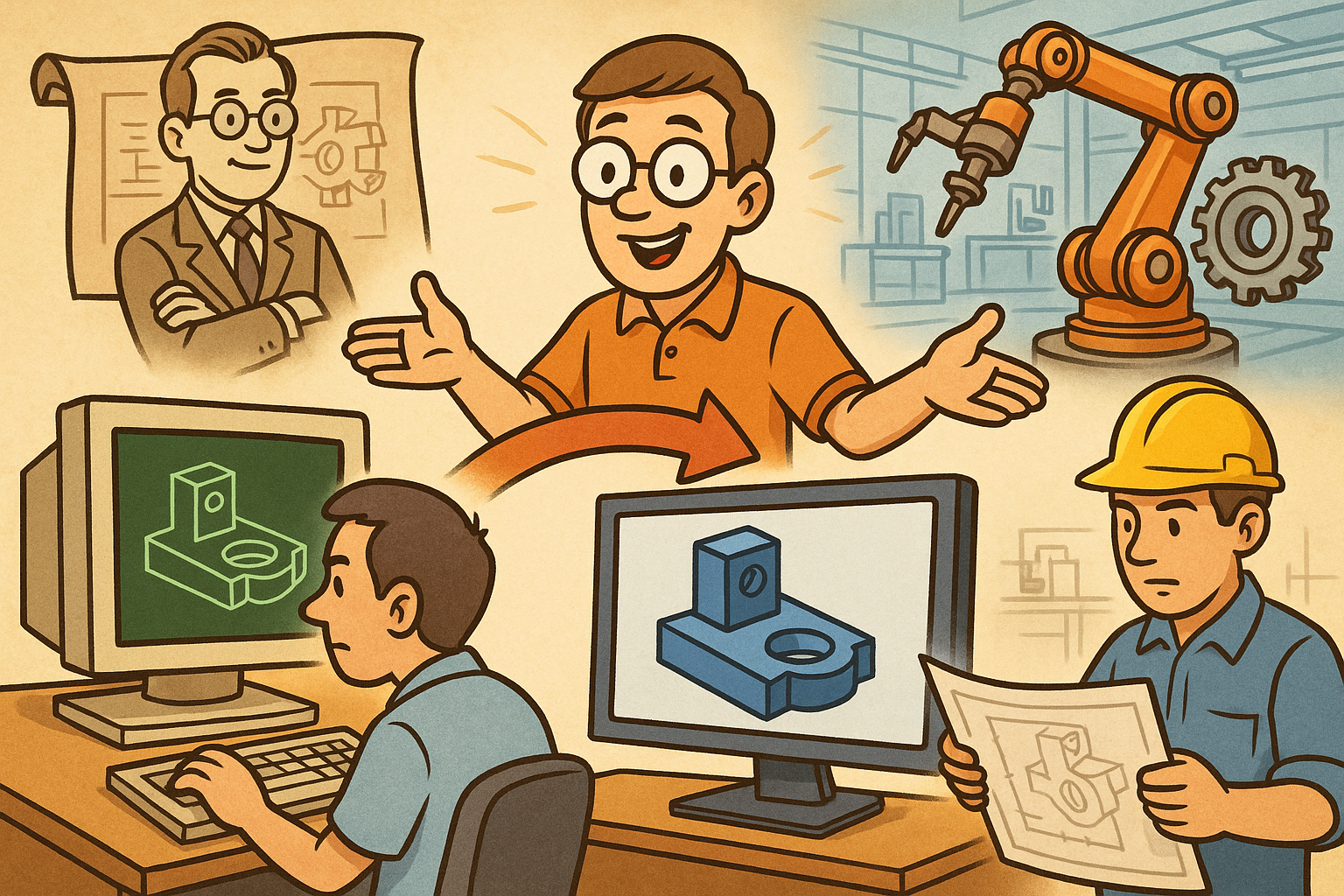

Design Software History: The Transformational Impact of SolidWorks on Mechanical Design Software History and Its Legacy in Modern Engineering Practices

October 25, 2025 8 min read

Introduction and Historical Context

The history of mechanical design software saw a dramatic shift with the emergence of SolidWorks in the late 1990s. Before SolidWorks entered the scene, the world of computer-aided design was dominated by expensive, cumbersome systems that required specialized training and often demanded high-end computing hardware. Engineers and designers had to rely on a collection of proprietary solutions that were not only difficult to use but also lacked the flexibility needed to respond to rapidly changing market demands. Many professionals in the mechanical design industry found themselves constrained by limited graphical capabilities, minimal integration between modeling and simulation, and a steep learning curve that hindered innovation. In this context, the introduction of SolidWorks was revolutionary, as it democratized advanced design techniques and provided an intuitive platform for drawing, modeling, and simulation. The software emerged at a time when the market was ripe for change and innovation, responding to persistent market challenges and the growing need for collaboration, efficiency, and adaptability in the engineering sector.

Evolution of the CAD Landscape

Prior to the arrival of SolidWorks, the CAD landscape was heavily influenced by legacy systems such as CATIA, Pro/ENGINEER, and Unigraphics, which primarily catered to large corporations with significant budgets. These platforms, while technically impressive, were often marred by their proprietary nature and inflexible frameworks. The industry faced several challenges:

- Limited accessibility due to expensive licenses and high hardware requirements

- Fragmented workflows that made collaboration across departments difficult

- Slow adaptation to emerging consumer needs and technological trends

Market Drivers and Technological Demand

In addition to overcoming legacy software constraints, SolidWorks was born in a period characterized by rapid technological advancements and growing market demands. Users were actively seeking systems that could not only produce high-quality visualizations but also integrate with simulation and manufacturing processes. The industry was also beginning to recognize the benefits of **collaborative engineering**; where interdisciplinary teams needed to work cohesively across various stages of product development. The following factors were key drivers in the market:

- Technological advancements in personal computing that made powerful design software accessible to a broader audience

- The need for rapid prototyping and iterative testing in design workflows

- An evolving market landscape where flexibility and integration with simulation tools became critical

Innovative Features and Technological Impact

SolidWorks is renowned for its pioneering contributions to the CAD landscape, particularly through the introduction of new modeling techniques and user-centric design innovations. One of the groundbreaking advancements offered by SolidWorks was the implementation of **feature-based modeling**. This approach allowed designers to construct models using a series of features—such as extrusions, cuts, and fillets—that built upon each other to form complex geometries. This method contrasted sharply with traditional approaches that typically required designers to manipulate raw geometry without the benefit of a structured, parametric framework. In addition, the software’s integration of simulation and design automation capabilities provided a comprehensive solution that bridged the gap between conceptual design and practical engineering. SolidWorks' technological impact is further underscored by its introduction of **user-friendly interfaces**, which simplified complex design operations, thereby reducing the learning curve and significantly boosting productivity. Engineers were no longer hindered by outdated, command-line driven systems; instead, they were empowered with intuitive graphical user interfaces that allowed quicker iterations and enhanced design accuracy.

Advancements in Modeling Techniques

The concept of **solid modeling** was not entirely new, but SolidWorks revolutionized it by embedding intelligent features that automatically adjusted as models evolved. This innovation enabled a more dynamic design process, where changes to one aspect of a model would propagate automatically throughout the entire design. The software’s ability to manage complex assemblies, simulate physical properties, and handle variations in design parameters paved the way for innovations that increased overall **design efficiency**. The advanced modeling tools allowed users to easily create and modify components, ensuring that the design process was both flexible and robust. Users benefited from prominent features such as:

- Parametric design capabilities that allowed for easy adjustments and updates

- Integrated simulations that provided real-time feedback on design performance

- An extensive library of pre-built features and components that accelerated the design process

Impact of Enhanced Collaboration and Automation

The revolutionary approach of SolidWorks extended beyond individual design capabilities. By fostering an environment of **collaborative engineering**, the software also redefined how multidisciplinary teams engaged in product development projects. The integration of design automation features allowed for the seamless sharing of data between various stages of the product lifecycle—from initial sketches to detailed simulations and final manufacturing. The software’s framework encouraged cross-functional communication by ensuring that every stakeholder had access to the latest design iterations and critical performance data. Bulleted below are the key aspects that furthered its technological impact:

- Real-time data sharing across different design and engineering departments

- Easy integration with other simulation and manufacturing software tools

- Enhanced documentation features that improved quality control

SolidWorks’ Evolution and Industry Influence

Over the last two decades, SolidWorks has undergone continuous evolution, marked by regular updates, feature enhancements, and strategic expansions that cemented its position as a leader in mechanical design software. From its humble beginnings as a disruptive CAD tool, SolidWorks quickly became a mainstay in the engineering sector, recognized for its capacity to streamline design workflows and facilitate complex modeling operations. A series of major software releases over the years introduced an array of new functionalities that further extended the software’s capability. These upgrades not only enhanced its already robust feature set but also anticipated emerging trends in the field of design automation. The progress of SolidWorks in synchronizing the demands of modern engineering with the pace of technological change has established a legacy that resonates across multiple industries, including automotive, aerospace, and consumer products. Each release has been coupled with refinements in user experience, performance, and integration capabilities that drive overall productivity and innovation.

Milestones in Product Development

Throughout its evolution, SolidWorks has reached several significant milestones that reflect both technological breakthroughs and market acceptance. Among these milestones were the introduction of advanced simulation tools, the expansion of assembly management features, and the seamless integration of design and manufacturing processes. Each version of SolidWorks brought with it enhancements that addressed user feedback and adapted to evolving industry standards. The timeline of product releases is punctuated by moments when the software set new benchmarks in **design efficiency**, flexibility, and reliability. SolidWorks influenced the way modern engineers approached design challenges by bridging the gap between conceptualization and production; for instance, the improved assembly management system allowed engineers to work concurrently on complex projects while ensuring that every component fit perfectly within the overall design. In addition, the expansion of file interoperability features enabled data sharing across various software platforms, fostering an ecosystem where collaborative work was both streamlined and productive.

Industry Adoption and Educational Impact

SolidWorks’ influence extends well beyond its direct application in manufacturing. The software has played a pivotal role in shaping design education and fostering a community of professional engineers. By integrating training modules, comprehensive documentation, and extensive support networks, SolidWorks has contributed to the development of educational programs that are now standard in engineering curricula worldwide. This commitment to education has ensured that new generations of engineers are well-versed in modern CAD practices right from the start of their careers. The influence of SolidWorks can be observed in various industries where it has fundamentally transformed mechanical design workflows. Key factors contributing to its influence include:

- Widespread adoption in academic institutions and technical training programs

- Establishment of user groups and online forums that facilitate knowledge exchange

- Continuous investment in developing educational content and certification programs

Conclusion

SolidWorks has undeniably left an indelible mark on the field of mechanical design, forever altering the way engineers conceptualize, iterate, and finalize their projects. The journey from its inception during an era of limited and expensive CAD applications to its current status as a versatile, integrated engineering platform is a testament to its groundbreaking innovations and sustained influence. As discussed, SolidWorks was instrumental in introducing **feature-based modeling**, which provided designers with a flexible framework to build complex products using intuitive and easily modifiable elements. The software not only revolutionized **solid modeling** by embedding powerful automation tools but also streamlined the entire design process through its incorporation of **user-friendly interfaces** and collaborative features. Its impact has transcended individual projects and sectors, establishing new paradigms in **collaborative engineering** and design automation that continue to mold current and future trends in product development.

Lasting Legacy and Future Directions

The legacy of SolidWorks is reflected in its ability to continuously adapt to emerging market requirements and technological advancements. While the software set the stage for modern CAD applications, it also pioneered concepts that are now considered foundational in the industry. The software’s integration of simulation and automated design features revolutionized the workflow by reducing iterative cycles and enhancing overall product quality. This forward-thinking approach enabled SolidWorks to establish powerful connections between industries, educational institutions, and professional communities, fostering a culture where continuous improvement and peer collaboration are at the forefront. As we look towards the future, the impact of SolidWorks remains evident in the persistent focus on integrating simulation, automation, and enhanced user interaction in emerging design software. This transformation has encouraged the adoption of cutting-edge technologies, such as artificial intelligence and cloud-based design, ensuring that innovation continues unabated in mechanical design.

Reflections on a Transformative Journey

In summarizing SolidWorks’ transformative journey, one cannot help but appreciate the convergence of visionary leadership, advanced technologies, and a relentless drive for innovation that the software embodies. As mechanical design continues to evolve, the pioneering spirit demonstrated by SolidWorks serves as a guiding principle for the development of next-generation design tools. The dedication to creating software that is both powerful in its functionality and accessible to its users has enabled SolidWorks to maintain its competitive edge over decades of technological shifts. In a rapidly changing industry, the emphasis on **design efficiency** and streamlined workflows continues to inspire engineers and developers alike. SolidWorks stands as a milestone in the history of manufacturing software, encouraging the pursuit of innovative solutions that bridge the gap between conceptual designs and practical implementations. The techniques and methodologies popularized by SolidWorks will undoubtedly continue to influence the evolution of mechanical design, encouraging future generations to build upon its legacy with even greater ambition and clarity.

Also in Design News

Cinema 4D Tip: Cinema 4D Parametric Primitive Blockout Workflow

February 20, 2026 2 min read

Read More

Revit Tip: Align linked Revit models using Shared Coordinates

February 20, 2026 2 min read

Read More

V-Ray Tip: V-Ray MultiMatte: Compact RGB ID Masks for Precise Compositing

February 20, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …