Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Design Software History: The Evolution and Impact of Finite Element Analysis in Design Software

October 06, 2024 5 min read

Introduction

Finite Element Analysis (FEA) has become an indispensable tool in the realm of design software, revolutionizing the way engineers and designers approach complex structural problems. By breaking down intricate geometries into smaller, manageable elements, FEA enables precise simulations of physical phenomena, which is crucial for optimizing designs and ensuring structural integrity. The importance of FEA in design software cannot be overstated, as it allows for the analysis of stresses, strains, and other critical factors that influence the performance of a design under various conditions. The development of FEA is deeply rooted in the advancements of computational technology and mathematical methodologies that emerged throughout the 20th century. From its early conceptual stages to its integration into modern design software, FEA has evolved significantly, reflecting the rapid progress in both engineering and computer science. Understanding the history of FEA provides valuable insights into how technological innovations have shaped current design practices and how they may continue to evolve in the future.

The Genesis of Finite Element Analysis

The origins of Finite Element Analysis can be traced back to the early concepts of structural analysis, where engineers relied on analytical methods to solve problems related to stress and deformation in materials. Traditional methods, such as classical beam theory and analytical solutions, were limited in their ability to handle complex geometries and heterogeneous material properties. These limitations highlighted the need for more robust and flexible analytical techniques. Early attempts to address these challenges involved simplifying assumptions that often compromised the accuracy of the results. The inadequacy of traditional methods in dealing with real-world engineering problems prompted researchers to explore alternative approaches that could accommodate the complexities inherent in modern structures.

A pivotal figure in the development of FEA was Richard Courant, a mathematician who, in the early 1940s, utilized variational methods to solve problems in structural mechanics. His work laid the foundation for the finite element method by introducing the idea of subdividing a continuous domain into discrete elements to simplify the analysis. Courant's application of variational methods allowed for the approximation of solutions to differential equations that govern physical phenomena. This approach was instrumental in advancing the mathematical framework necessary for FEA. The combination of variational principles with numerical methods provided a powerful tool for engineers to tackle complex structural problems with greater accuracy.

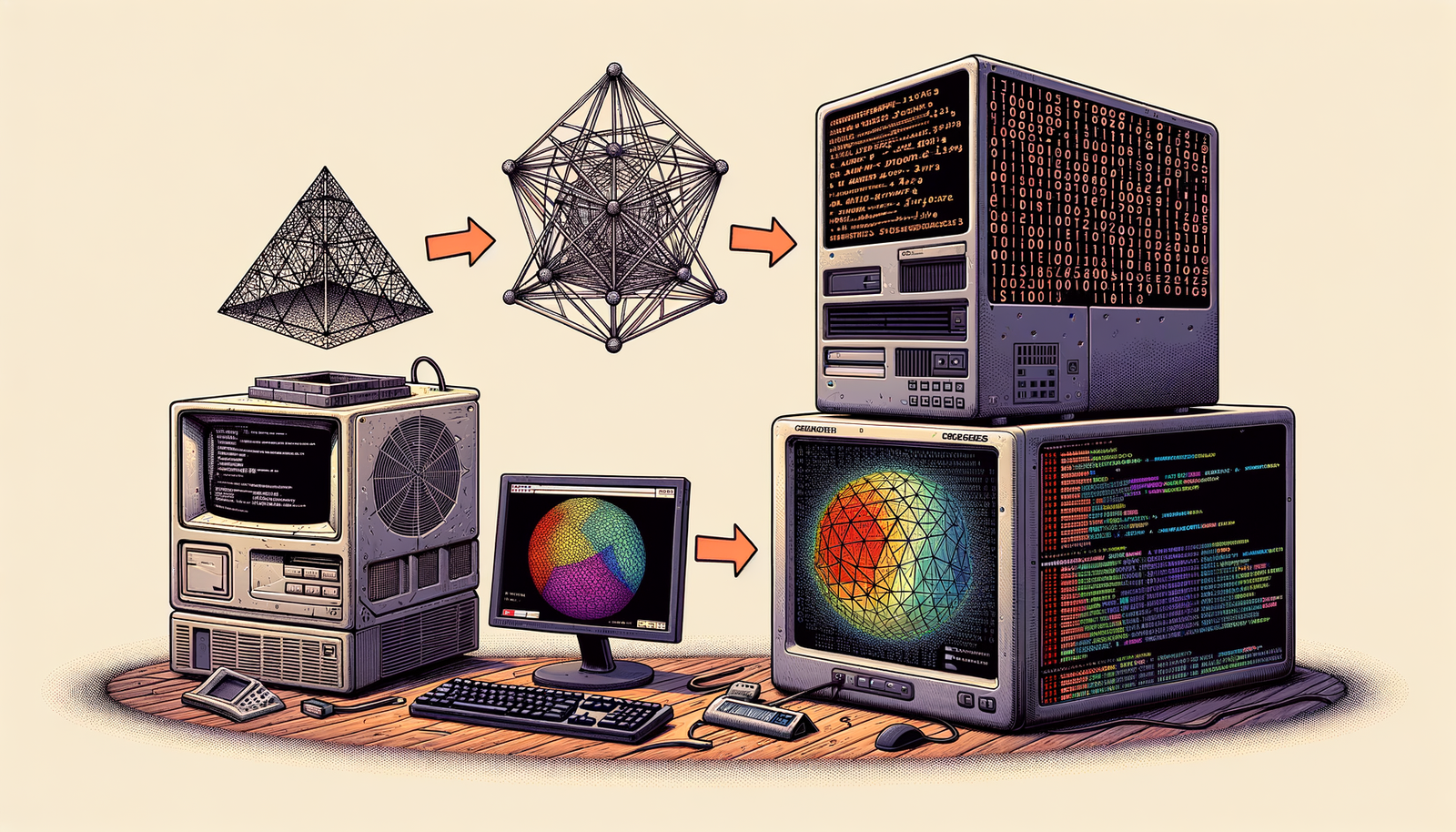

The advent of digital computers in the mid-20th century propelled the development of FEA software, enabling the practical application of these mathematical concepts to real-world engineering problems. Early FEA programs were developed for specific applications in engineering and physics, focusing on areas such as stress analysis, heat transfer, and fluid dynamics. These initial software tools were rudimentary by today's standards but represented a significant leap forward in computational engineering. They allowed for the numerical simulation of physical systems, providing engineers with insights that were previously unattainable. The introduction of early FEA software marked the beginning of a new era in engineering analysis, where computational methods became integral to the design process.

The Rise of Finite Element Analysis in Design Software

The evolution of FEA software during the 1970s and 1980s was characterized by significant technological advancements and increased user adoption. As computational power grew, FEA programs became more sophisticated, allowing for more complex analyses and broader applications across different engineering fields. The development of graphical user interfaces and pre- and post-processing tools made FEA software more accessible to engineers who were not specialists in numerical methods. This period saw the integration of FEA into mainstream engineering design processes, with software becoming an essential tool for verifying and optimizing designs before physical prototyping.

Several industries began to recognize the benefits of incorporating FEA into their design workflows. The aerospace and automotive sectors, in particular, leveraged FEA to improve the safety and performance of their products. The ability to simulate and analyze the behavior of structures under various loading conditions without the need for extensive physical testing resulted in significant cost and time savings. Additionally, FEA facilitated the exploration of innovative designs and materials, contributing to advancements in technology and performance. The widespread adoption of FEA in these industries underscored its value as a critical component of modern engineering design.

Prominent companies played a crucial role in advancing the FEA landscape by developing robust software solutions that catered to the growing needs of engineers. Companies like ANSYS and ABAQUS emerged as leading providers of FEA software, offering comprehensive tools that covered a wide range of analysis types, including structural, thermal, and fluid dynamics simulations. ANSYS, founded in 1970 by John Swanson, became known for its user-friendly interface and powerful simulation capabilities. ABAQUS, developed in the late 1970s, gained recognition for its advanced nonlinear analysis features and ability to handle complex material behaviors. These companies invested heavily in research and development, pushing the boundaries of what could be achieved with FEA and setting industry standards for simulation accuracy and reliability.

Current Trends and Future Directions

The impact of increased computational power on FEA software capabilities and accuracy has been profound. Modern high-performance computing allows for the simulation of extremely complex models with millions of degrees of freedom, resulting in highly detailed and accurate analysis results. Parallel processing and cloud computing have enabled faster solution times, making it feasible to perform comprehensive simulations that were previously impractical due to computational limitations. Enhanced computational capabilities have also facilitated the use of more sophisticated material models and the inclusion of multiphysics interactions, where multiple physical phenomena are simulated simultaneously. These advancements have expanded the applicability of FEA across various disciplines and increased the confidence engineers have in simulation results.

The integration of FEA with other design technologies has become a significant trend in the engineering field. The combination of FEA with lightweight design principles allows engineers to optimize structures for minimum weight while maintaining or improving performance. This is particularly important in industries such as aerospace and automotive, where weight reduction leads to increased efficiency and reduced emissions. Additionally, FEA plays a critical role in additive manufacturing, where simulation is used to predict and mitigate issues related to material behavior and structural integrity during the printing process. The ability to simulate the additive manufacturing process helps in designing components that are optimized for 3D printing, reducing the need for trial-and-error approaches and enhancing the reliability of printed parts.

Looking toward the future, FEA is poised to play a vital role in emerging fields like materials science and bioengineering. In materials science, FEA aids in the development of new materials by simulating microscopic interactions and predicting macroscopic properties. This accelerates the discovery of materials with tailored characteristics for specific applications. In bioengineering, FEA is used to simulate biological structures and systems, contributing to advances in medical devices, prosthetics, and understanding of physiological processes. However, these opportunities come with potential challenges, such as the need for accurate material models at different scales and the integration of biological variability into simulations. Addressing these challenges requires ongoing research and the development of new methodologies within the FEA framework.

In summary, the evolution of Finite Element Analysis reflects the broader trajectory of technological advancement in engineering and design software. From its origins in mathematical theory to its current applications in cutting-edge industries, FEA has profoundly influenced how engineers approach problem-solving. The continued growth of computational power and integration with other technologies suggests that FEA will remain a cornerstone of engineering analysis, driving innovation and efficiency in design processes across various fields.

Also in Design News

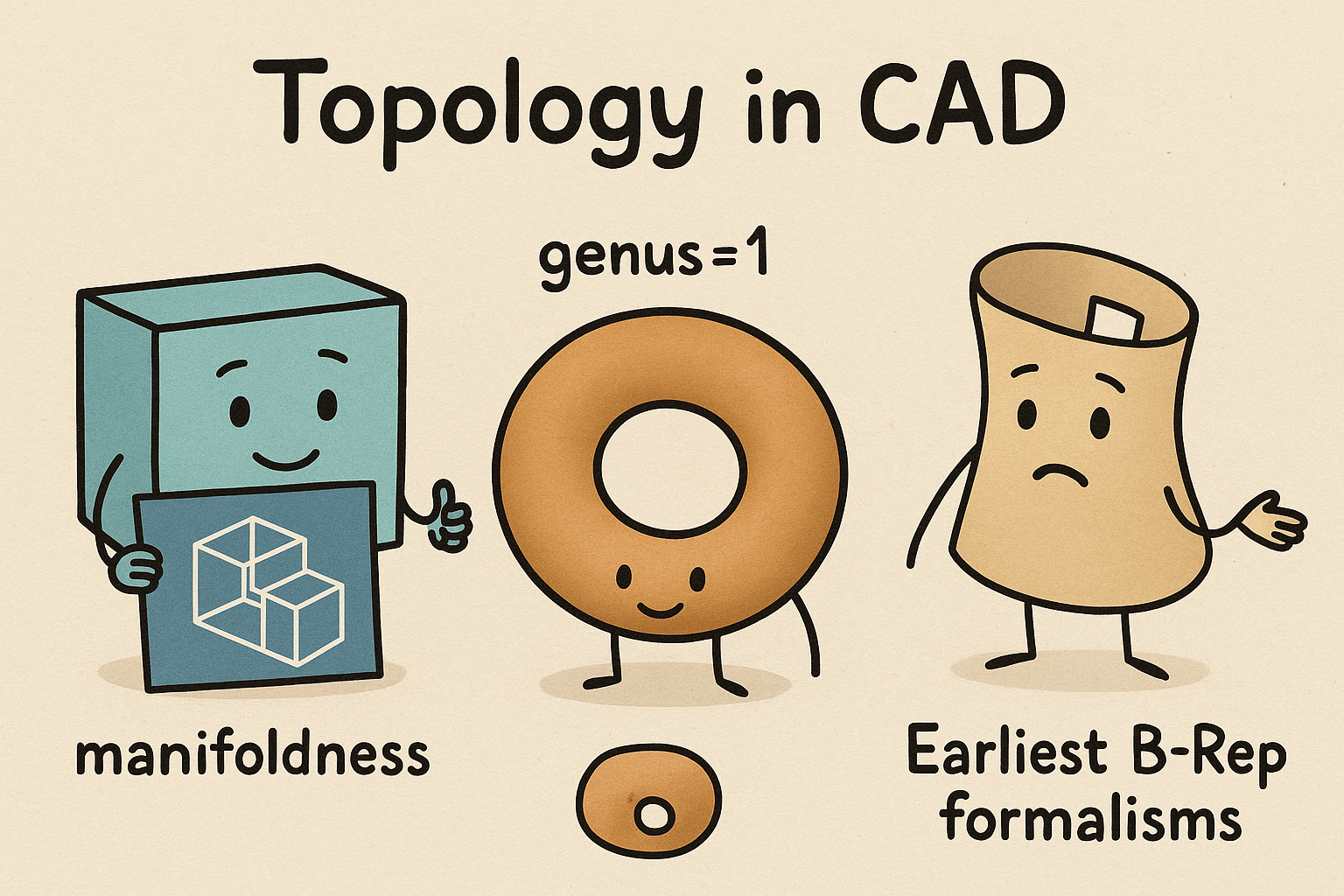

Design Software History: Topology in CAD: Manifoldness, Genus, and the Earliest B‑Rep Formalisms

January 02, 2026 14 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …