Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Design Software History: The Evolution and Impact of Computer-Aided Manufacturing: From Numerical Control to Industry 4.0

September 30, 2024 5 min read

Introduction to Computer-Aided Manufacturing (CAM)

Computer-Aided Manufacturing (CAM) represents a pivotal advancement in the realm of modern manufacturing processes. At its core, CAM involves the use of computer software and hardware to automate and control the production of goods. This technology bridges the gap between computer-aided design (CAD) models and the physical manufacturing environment, enabling the precise and efficient production of complex components. The purpose of CAM is to enhance the capabilities of manufacturing systems by integrating computational power into the planning, control, and execution of production operations.

The significance of CAM in today's industrial landscape cannot be overstated. By harnessing the power of computers, manufacturers are able to achieve unprecedented levels of productivity, precision, and efficiency. CAM systems facilitate the automation of manufacturing processes, reducing the reliance on manual labor and minimizing the risk of human error. This leads to higher quality products, faster production times, and cost savings that are critical in a competitive global market.

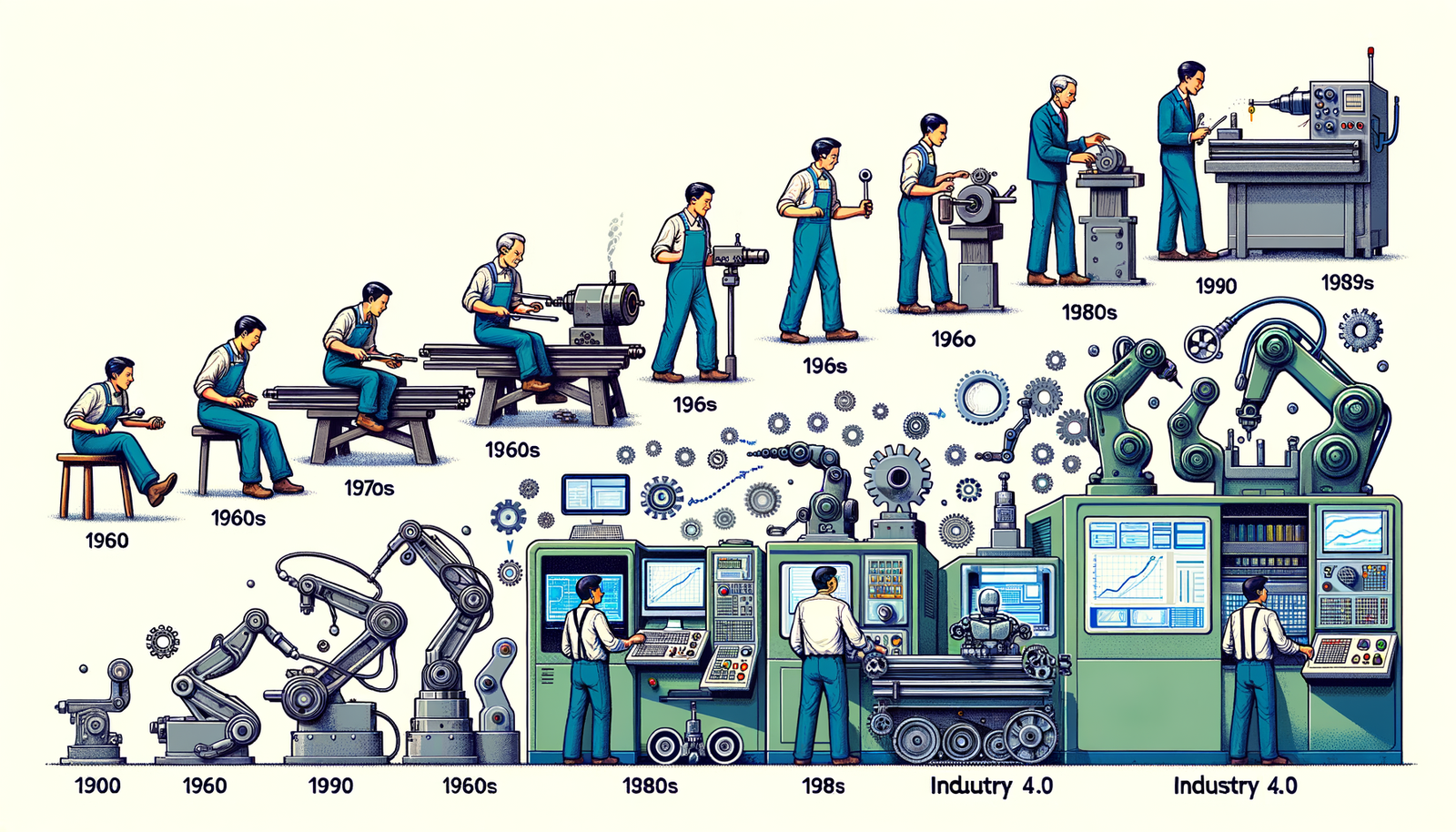

Before the advent of CAM, manufacturing was predominantly a manual endeavor. Craftsmen and technicians relied on their skills and rudimentary tools to create products, a process that was both time-consuming and prone to inconsistencies. The Industrial Revolution introduced mechanization, but even then, the control over machines was limited. Operators manually adjusted machinery, which limited the complexity and precision of manufactured parts. The lack of automated control systems meant that scaling production while maintaining quality was a significant challenge. This historical context highlights the transformative impact that CAM has had on manufacturing, marking a shift from manual craftsmanship to automated precision engineering.

Early Developments in CAM Technology

The journey towards modern CAM technology began with the initial forays into automated manufacturing systems, particularly through the development of numerical control (NC) systems. NC technology emerged as a revolutionary concept wherein machines could be controlled by a set of coded instructions, rather than by manual operation. This innovation laid the foundational framework for the automation of machine tools, allowing for more precise and consistent production.

One of the key figures in the development of NC technology was John T. Parsons, often referred to as the "father of numerical control." In the 1940s, Parsons, in collaboration with his engineer Frank L. Stulen, pioneered the use of punched cards to control machine tools. Their work at the Parsons Corporation in Traverse City, Michigan, was initially driven by the need to produce complex helicopter rotor blades with greater accuracy. This led to the introduction of NC systems, which utilized data input to guide machinery movements, reducing reliance on human operators.

The evolution from NC to Computer Numerical Control (CNC) in the 1960s marked a significant milestone in manufacturing technology. CNC systems improved upon NC by incorporating computers to interpret and execute control instructions. This transition allowed for more complex programming and flexibility in manufacturing processes. Machines could now store multiple programs and switch between tasks more efficiently, greatly enhancing production capabilities.

The integration of Computer-Aided Design (CAD) and CAM tools was another critical development during this era. Pioneers such as Ivan Sutherland, who developed the Sketchpad system in 1963, played a crucial role in this integration. Sketchpad was one of the first programs to utilize a graphical user interface for design purposes, allowing for more intuitive interaction with computers in the design process. The combination of CAD and CAM enabled the seamless transfer of design data to manufacturing systems, significantly reducing the time from concept to production.

Advancements in CAM Software and Techniques

The transition from basic CNC programming to sophisticated CAM solutions marked a new chapter in manufacturing technology. Early CNC machines required complex and time-consuming programming, often using G-code language, which was not user-friendly for many operators. The development of advanced CAM software transformed this landscape by providing more accessible interfaces and powerful features that streamlined the programming process.

Software such as Mastercam, GibbsCAM, and Autodesk Fusion 360 emerged as industry leaders in CAM solutions. Mastercam, developed by CNC Software, Inc. in 1983, offered a range of tools for both design and manufacturing, becoming one of the most widely used CAM packages globally. GibbsCAM, introduced by Gibbs and Associates in 1984, focused on providing intuitive interfaces for CNC programming, catering to both novice and experienced users. Autodesk Fusion 360, released in the 2010s, integrated cloud-based CAD and CAM capabilities, allowing for collaborative design and manufacturing workflows.

These software solutions introduced advanced technologies that significantly impacted manufacturing capabilities. One such technology is multi-axis machining, which allows CNC machines to move cutting tools along multiple axes simultaneously. This capability enables the creation of complex geometries and intricate parts that were previously difficult or impossible to manufacture. Multi-axis machining expands the possibilities for designers and engineers, facilitating innovation across various industries.

The rise of simulation and verification tools within CAM software brought about another leap forward. These tools allow manufacturers to simulate machining processes virtually before actual production. Benefits include:

- Detection of potential errors or collisions, reducing waste and machine downtime.

- Optimization of tool paths for efficiency and precision.

- Improved safety by anticipating and mitigating risks within the machining process.

The shift towards additive manufacturing, commonly known as 3D printing, has complemented traditional CAM processes. Additive manufacturing builds objects layer by layer, offering unique advantages such as reduced material waste and the ability to produce complex internal structures. The integration of CAM with additive techniques has expanded manufacturing possibilities, allowing for hybrid processes that combine subtractive and additive methods. This synergy enables manufacturers to select the most appropriate method for each component, optimizing both performance and cost.

The Future of CAM in Manufacturing

The current trends and innovations in CAM technologies are shaping the future of manufacturing in profound ways. One significant development is the integration of Artificial Intelligence (AI) and Machine Learning (ML) within CAM systems. AI and ML enable CAM software to learn from data and improve over time, leading to enhanced process optimization. These technologies can analyze vast amounts of manufacturing data to identify patterns, predict maintenance needs, and suggest improvements to machining strategies. The result is a more efficient and responsive manufacturing process that can adapt to changing conditions and requirements.

The role of Industry 4.0 and the Internet of Things (IoT) is also pivotal in the evolution of CAM. Industry 4.0 refers to the fourth industrial revolution, characterized by smart manufacturing and the interconnectivity of machines, systems, and processes. IoT devices collect and exchange data across the manufacturing environment, providing real-time insights and enabling automated adjustments. In smart manufacturing environments, CAM systems are integrated with sensors and networked machines, creating a cohesive ecosystem that enhances decision-making and operational efficiency.

Despite these advancements, the CAM industry faces several challenges and opportunities. One major challenge is the need for continuous training and adaptation among the workforce. As CAM technologies become more sophisticated, the demand for skilled professionals who can operate and maintain these systems increases. Manufacturers must invest in education and training programs to equip their employees with the necessary skills. This includes understanding advanced software features, interpreting data analytics, and staying abreast of emerging technologies.

Sustainability is another critical focus area, with a push towards eco-friendly manufacturing processes. CAM systems can contribute to sustainability by optimizing material usage, reducing waste, and improving energy efficiency. Manufacturers are increasingly adopting practices that minimize environmental impact, driven by both regulatory requirements and consumer demand for sustainable products. CAM technologies enable precise control over manufacturing processes, allowing for the implementation of greener strategies without compromising on quality or productivity.

In conclusion, Computer-Aided Manufacturing stands as a cornerstone in the ongoing evolution of the manufacturing industry. Its ability to enhance productivity, precision, and efficiency has transformed how goods are produced, enabling manufacturers to meet the demands of a complex and dynamic market. As CAM continues to integrate with emerging technologies like AI, IoT, and additive manufacturing, it will play a pivotal role in shaping the future of manufacturing. Embracing these innovations, while addressing the accompanying challenges, will be essential for manufacturers aiming to remain competitive and sustainable in the years to come.

Also in Design News

Rhino 3D Tip: ReplaceBlock: Batch update block instances from external files while preserving transforms

December 23, 2025 2 min read

Read More

Design Software History: Collaboration in Design Software: From File-Based PDM to Cloud-Native Co-Editing and Design Threads

December 23, 2025 9 min read

Read More

End-to-End Encryption for CAD/PLM: Protecting Design IP in Cloud Workflows

December 23, 2025 13 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …