Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Design Software History: Historical Evolution and Technological Milestones in the Development of Design Software for Electronics Manufacturing

August 14, 2025 11 min read

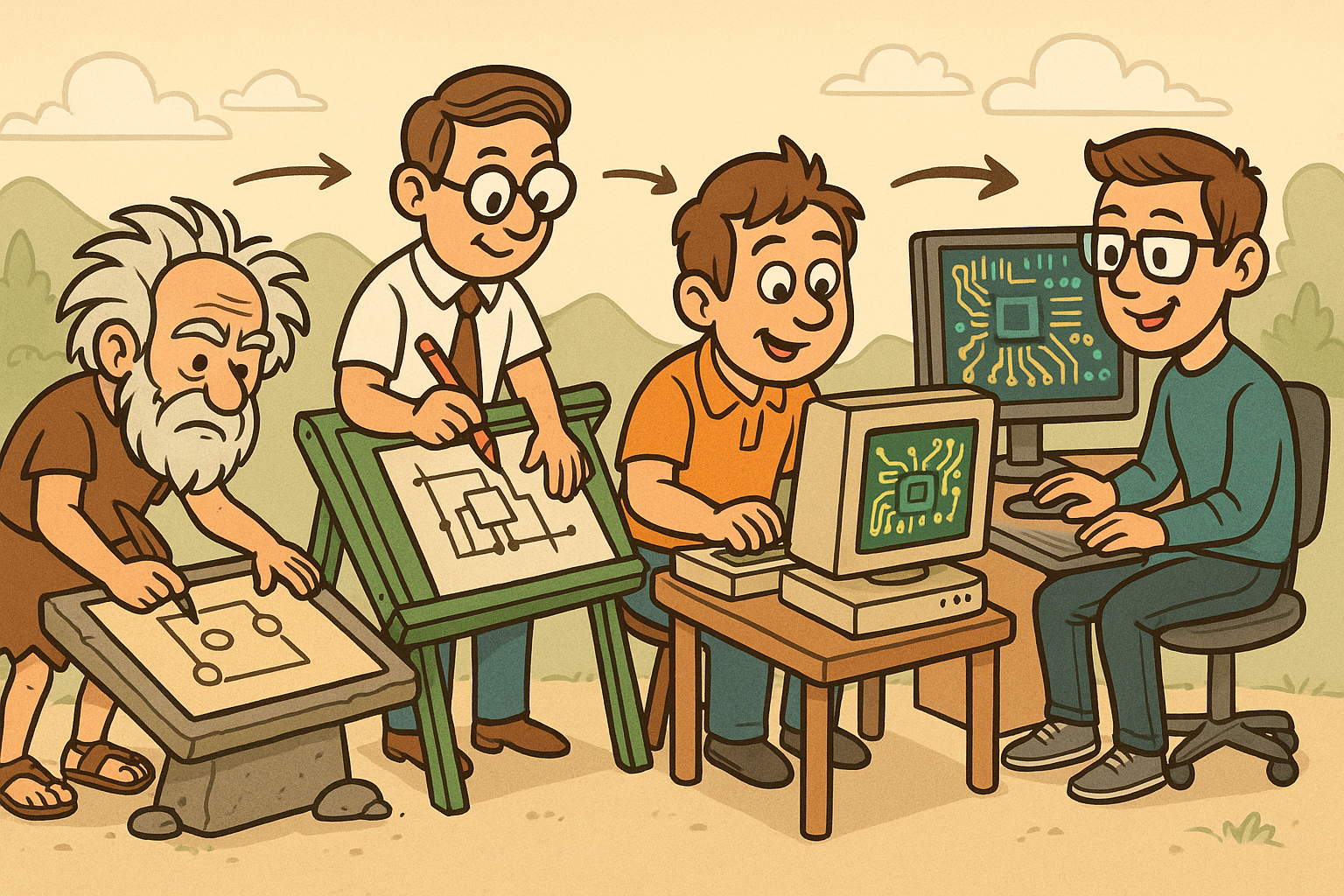

Historical Foundations and the Emergence of Design Software in Electronics

The origins of design software can be traced back to the early days of CAD applications when engineers and architects were transitioning from traditional manual drafting to digital solutions. The initial systems, originally developed for general computer-aided drafting, gradually evolved as enthusiasts recognized the potential to repurpose these tools for electronics manufacturing. Early pioneers in the field cleverly repurposed the technology, paving the way for complex applications that could model intricate circuitry and electronic components. In a period marked by rapid technological transitions, the synergy between computer hardware improvements and novel software algorithms contributed significantly to the evolution of design platforms. The specific focus on the electronics sector was propelled by growing demands within industries that required high precision in circuit design, concept visualization, and simulation of electrical behavior.

Origins from General CAD Architectures

Traditional CAD systems provided a foundation that hosted rudimentary drafting functions. Over time, these functionalities expanded with additional features such as geometric constraints and symbolic representation, crucial for modeling electrical circuits and electronic components accurately. Engineers began noticing that manual drafting could no longer sustain the fast-paced demands of production and layout requirements in electronics. This recognition led to the implementation of computer algorithms designed to automate many aspects of the design process. The resulting integration of digital design paradigms included the use of early simulation capabilities and more refined drawing techniques, which set the stage for modern design software. Among the notable innovations were the establishment of feature-based modeling techniques and the initial use of graphical user interfaces, which improved usability for electronic designers. The evolving technology was marked by a clear transition from hand-drawn schematics to more sophisticated, automated representations, triggering widespread industrial interest.

Electronics Manufacturing Influence and Early Innovations

The demand for precision and efficiency in electronics manufacturing spurred significant advancements in digital drafting and simulation technology. Manufacturers and design houses sought solutions that could promise accuracy beyond the reach of manual methods. Early contributions by influential companies catalyzed the shift, incorporating advanced algorithms that could simulate electrical performance under varied conditions. These innovations were facilitated by the rapid expansion in computing power, which transformed design software from static image rendering systems into dynamic platforms capable of handling complex calculations and simulations. Bullet lists that clearly outline these contributions include:

- Transition from manual drafting to computer-aided designs

- Integrating symbolic representation with geometric precision

- Adopting early algorithm-based simulation methods

- Expanding CAD capabilities to include dynamic system responses

Key Visionaries and Milestones in Early Design Software Integration

At the very inception of design software, numerous visionaries played pivotal roles in transforming theoretical concepts into practical applications. These industry leaders saw the opportunity to employ computers not only for graphical representations but also to solve intractable engineering problems. Visionaries from both academia and industry were instrumental in promoting the integration of design software within electronics, using pioneering strategies to overcome the limitations of early digital systems. Their collaborative efforts drove innovation through investments in research and development, enabling the adaptation of digital tools to meet the specific needs of electronic hardware production. Notable companies emerged as frontrunners, and their relentless pursuit of refinement in software solutions led to significant milestones that defined the era, with precision engineering and automation becoming the cornerstone of the new design paradigm.

Contributions from Leading Companies and Innovators

Key players from the early days included companies that would later dominate the design software industry. These firms built comprehensive solutions by bridging the gap between theoretical computational processes and the practical needs of electronics design. Early innovators experimented with parameters that defined electronic behavior, thereby enabling scalable design platforms. Their efforts can be detailed via the following points:

- Development of tools that converted manual drafts into scalable digital blueprints

- Implementation of modular design techniques that offered flexibility in circuit layout

- Utilization of early computer graphics to enhance clarity in design representation

- Emphasis on creating adaptive systems that could evolve alongside technological advancements

Technological Advancements: From 2D Drafting to Dynamic 3D Modeling

The evolution of design software witnessed transformative changes as technology advanced from basic 2D drafting tools to sophisticated 3D modeling and simulation platforms. The journey from static, flat representations to dynamic, interactive three-dimensional environments marked a significant leap in design capabilities. Early CAD systems were primarily limited to two-dimensional visualizations that served well for simple drafts and layouts. However, as the complexity of electronics increased, the limitations of 2D systems became very apparent. Modern engineers and designers began requiring a more comprehensive visual understanding of their projects, one that could not only depict but also simulate the physical behavior of electronic components under various conditions. This technological revolution was made possible through the integration of robust algorithms and real-time computational models that allowed for detailed simulations and error detection within a 3D environment. The integration of these capabilities revolutionized production cycles, cost estimations, and error minimization.

Evolutionary Steps and Key Innovations

Early steps in this evolution included the incremental incorporation of 3D functionalities into traditional CAD systems. The progressive improvements encompassed:

- Development of deep computational geometry focused on translating 2D designs into 3D forms

- Enhancement of dynamic simulation features, including real-time adjustments and error feedback loops

- Implementation of finite element analysis to predict physical behavior under stress conditions

- Integration of user-friendly interfaces that bridged technical complexity with operational ease

Innovative Algorithms and Collaborative Research Shaping Design Precision

The development of algorithms and the collaborative efforts between academic institutions and industry have remained central to improving design precision in electronics manufacturing. As early as the inception of automated design software, engineers recognized the immense potential that lay in incorporating mathematical models and simulations to predict and refine design outcomes. Advanced algorithms ushered a new era by offering enhanced capabilities such as real-time optimization, finite element analysis, and error correction, which collectively improved the reliability and efficiency of design operations. Through collaborative research initiatives, experts from various fields contributed to a robust body of knowledge that was rapidly assimilated by design software. This intermingling of theoretical mathematics and practical application proved indispensable for solving complex design problems, especially those related to high-density electronics where even minor deviations could have significant repercussions.

Contributions Through Academic and Industrial Collaborations

The combined expertise from academia and industry culminated in several breakthroughs that have since become the bedrock of modern design software:

- Development and integration of domain-specific optimization algorithms

- Creation of simulation frameworks capable of predicting thermal and mechanical responses

- Implementation of graph-based algorithms that enhanced the visualization of electronic circuits

- Collaboration on research projects that bridged computational geometry with practical design needs

Influential Software Tools and Industry Milestones in Electronics Manufacturing

As design software matured, a number of influential tools emerged that fundamentally reshaped the electronics manufacturing landscape. These platforms turned intricate design challenges into manageable workflows. They provided engineers with robust tools capable of handling complex simulations, integrated designing, and error checking across multiple dimensions. With the rapid pace of technological innovation, software tools began incorporating features that not only enhanced visual representations but also delivered actionable insights into the manufacturing process. In many instances, pioneering tools utilized cutting-edge computational methods to streamline the verification and validation stages, thereby ensuring that designs adhered to stringent industrial standards. Today’s systems stand on the shoulders of these early breakthroughs, which illustrated the immense potential of integrating simulation, modeling, and real-time feedback into a single platform.

Industry Milestones and Key Technological Breakthroughs

The journey witnessed several significant milestones that marked major technological breakthroughs:

- Adopting grid-based and vector-based representations for clearer visualizations

- Integrating simulation modules that could predict circuit behavior under varied operational demography

- Establishing robust user interfaces that became industry standards for design software

- Emphasizing scalable architecture to cater to increasingly complex electronics

Collaborations between Hardware and Software Experts Reshaping the Industry

The convergence of hardware development and software innovation has played an essential role in driving improvements in electronics manufacturing. As design requirements grew in complexity, early partnerships between hardware manufacturers and software developers became increasingly important. These collaborations were instrumental in creating comprehensive design environments that provided a seamless transition from conceptual models to tangible products. By integrating detailed simulations with hardware constraints, the software was able to predict potential conflicts and optimize designs to achieve optimal performance. This synergistic relationship not only bridged the gap between theoretical design and practical implementation but also facilitated innovations that would redefine production methodologies in the electronics realm. The cross-disciplinary partnerships brought together unique insights and expertise that accelerated the pace of technological innovation.

Synergies and Integrated Workflows

The joint efforts between hardware and software experts can be summarized through the following key points:

- Developing integrated systems that combine simulation, design, and manufacturing controls

- Creating unified databases for design parameters that ensure consistency across design and production stages

- Utilizing real-time feedback mechanisms to iteratively refine design efficiency

- Emphasizing end-to-end solutions that minimize error propagation from design to final product

Modern Design Software and the Transformation of Electronics Manufacturing

In the contemporary landscape, design software has reached unprecedented levels of sophistication, fundamentally transforming the ways in which electronics manufacturing is executed. Modern platforms are no longer confined to static design representations; they now incorporate features such as AI-driven analytics and cloud-based collaboration tools that streamline the entire design-to-production cycle. These cutting-edge solutions allow manufacturers to deploy real-time simulations, predictive maintenance, and adaptive feedback mechanisms during the design process. The integration of advanced computing technologies has enabled companies to achieve higher degrees of precision and efficiency, particularly as the demand for miniaturization and high-performance components continues to soar. The ability to accurately model thermal, electrical, and mechanical interactions in a virtual environment has significantly reduced the need for costly physical prototyping and extensive trial and error in production.

Cloud-Based and AI-Driven Solutions in Modern Platforms

One of the most significant trends in modern design software is the incorporation of cloud and AI-based methodologies. These advancements provide design teams with unprecedented flexibility and scalability by enabling:

- Real-time collaboration among geographically dispersed teams

- Data-driven decision-making through sophisticated analytics and predictive modeling

- Automation of repetitive design tasks, thereby accelerating the iterative design process

- Enhanced simulation capabilities that integrate multiple physical domains simultaneously

Emerging Trends: Augmented Reality and Next-Generation Simulation Tools

Looking forward, the trajectory of design software development is poised to embrace transformative technologies such as augmented reality (AR) and next-generation simulation tools. These emerging trends promise to revolutionize the way designers interact with digital models, offering a more immersive and intuitive experience that bridges the gap between the digital and physical worlds. Augmented reality, for instance, enables engineers to overlay virtual prototypes onto physical work environments, thereby providing immediate feedback on design feasibility and functional integration. Additionally, next-generation simulation tools, underpinned by increasingly powerful processing capabilities and refined algorithmic models, are set to further enhance the precision and predictive quality of design outputs. The application of these advanced technologies will not only aid in overcoming current complexities—such as component miniaturization and integration challenges—but also open pathways to entirely new design paradigms.

Fostering Innovation with Augmented Reality and Advanced Simulation

The impact of augmented reality combined with enhanced simulation tools is expected to be profound. Key benefits include:

- Immersive design reviews and interactive visualizations that facilitate better decision-making

- Early validation of design concepts by visualizing operational environments in a real-world context

- Streamlined communication between design, engineering, and manufacturing departments

- Enhanced ability to detect potential issues before physical prototyping, reducing both time and cost

Conclusion: Bridging Historical Innovations with Future Possibilities in Design Software

The historical journey of design software, from its humble beginnings in basic CAD applications to the sophisticated multi-dimensional platforms of today, has been marked by relentless innovation, bold visionaries, and groundbreaking technological advancements. The evolution from manual drafting to fully integrated design environments has not only transformed electronics manufacturing but also provided a framework for addressing the ever-increasing complexities of modern engineering. Today’s design software stands as a testament to decades of collaborative progress between hardware and software experts, researchers, and industry leaders who continuously push the boundaries of what is possible. As we look toward the future, emerging trends such as augmented reality integration and next-generation simulation tools are poised to further revolutionize the field, ensuring that design solutions remain agile, precise, and economically viable in an increasingly dynamic global market.

Key Takeaways and Future Directions

The evolution of design software is a story of relentless innovation and cross-disciplinary collaboration, marked by:

- The seamless transition from manual drafting techniques to automated, algorithm-based design systems

- Significant milestones driven by early industry leaders and pioneering companies

- The transformative impact of integrating advanced simulation and cloud-based solutions

- A promising future where augmented reality and next-generation tools redefine design workflows

Also in Design News

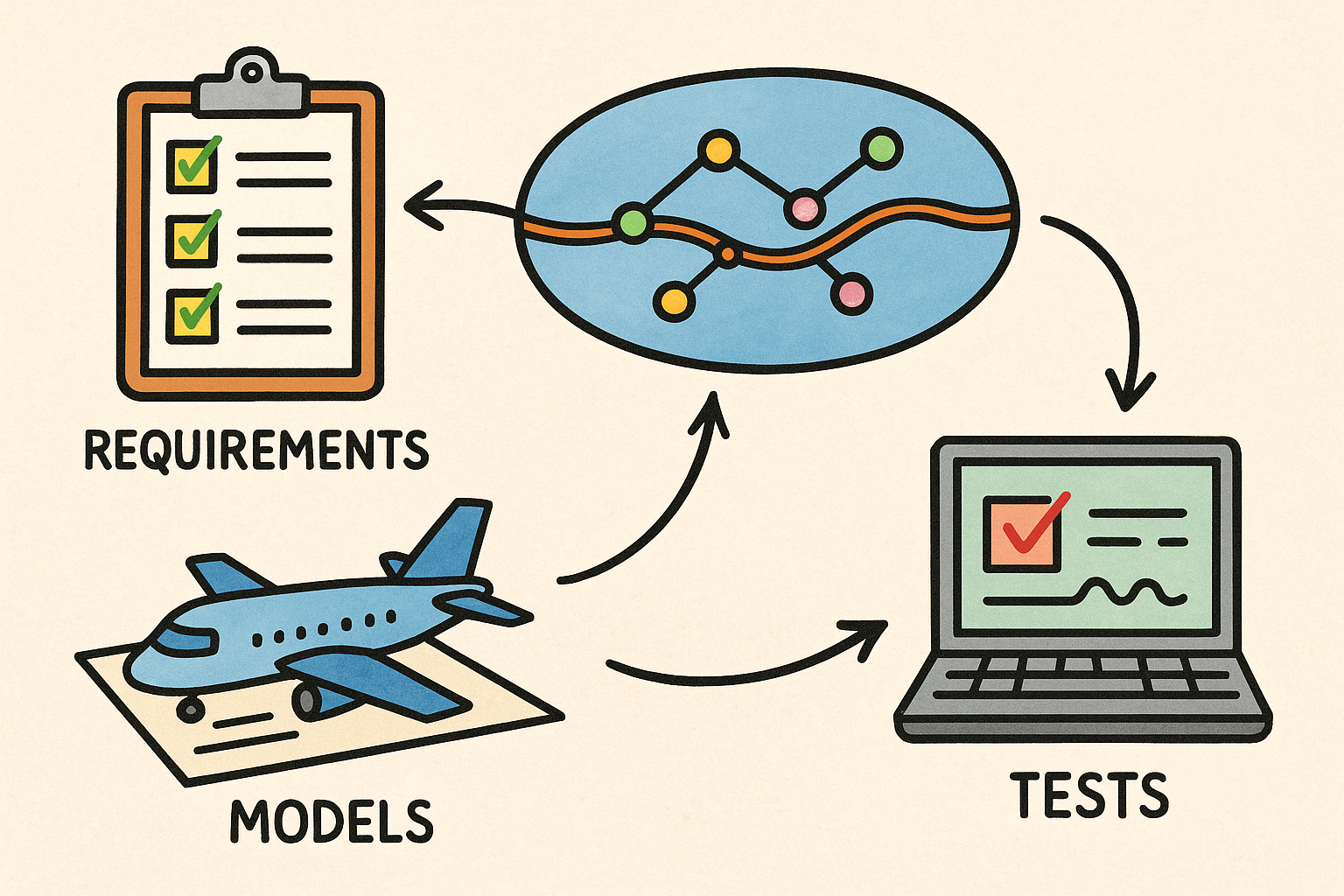

Semantics-First Digital Thread: Linking Requirements, Models, and Tests for Traceable Engineering

February 17, 2026 12 min read

Read More

Cinema 4D Tip: UV Tiling Best Practices for Cinema 4D and Redshift

February 17, 2026 2 min read

Read More

V-Ray Tip: Reflection Catcher Workflow for Photoreal Plate Integration

February 17, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …