Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

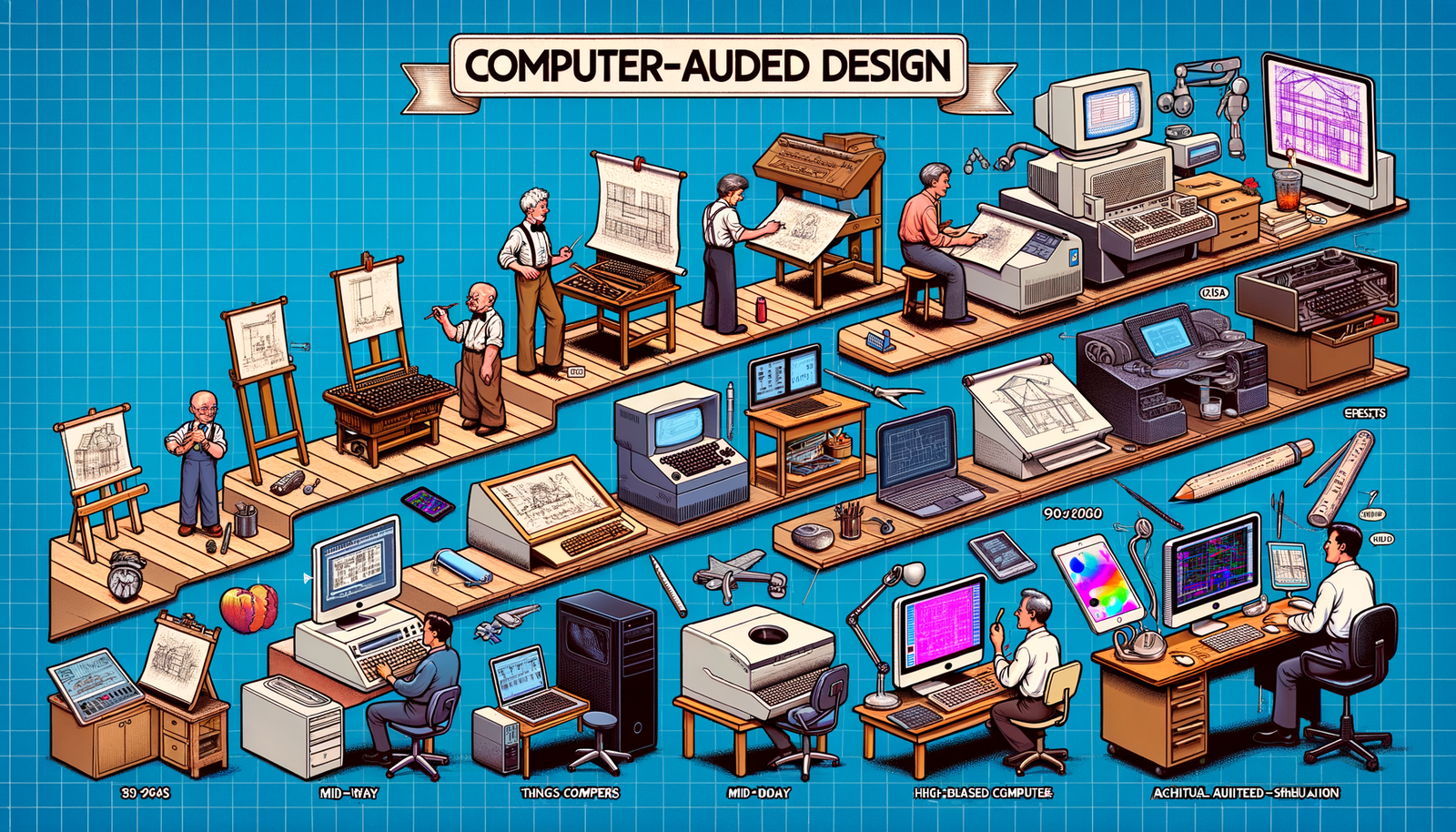

Design Software History: Evolution of Computer-Aided Design: From Early Tools to Modern Innovations in Engineering and Architecture

February 06, 2025 7 min read

The history of design software is a rich tapestry of innovation and technological advancement that has profoundly transformed the field of engineering. From the rudimentary beginnings of computer-aided design (CAD) to the sophisticated tools available today, the evolution of design software has enabled engineers to tackle increasingly complex projects with unprecedented precision and efficiency.

Introduction to Early CAD Tools

Computer-Aided Design (CAD) emerged as a revolutionary tool that fundamentally changed the way engineers approached design and drafting. At its core, CAD is a technology that uses computer systems to assist in the creation, modification, analysis, or optimization of a design. It serves the purpose of increasing the productivity of the designer, improving the quality of design, enhancing communication through documentation, and creating a database for manufacturing. Prior to the advent of CAD tools, engineers relied heavily on manual drafting techniques using pencils, paper, and drafting boards. This process was not only time-consuming but also prone to errors, limiting the complexity and precision of engineering projects. The technological landscape before CAD was marked by mechanical drawing methods, slide rules, and early calculators, which constrained the scale and intricacy of designs that could be practically realized.

Pioneering Contributions and Visionaries

The genesis of CAD can be traced back to the groundbreaking work of Dr. Ivan Sutherland, whose development of Sketchpad in 1963 laid the foundational principles for interactive computer graphics. Sketchpad was a revolutionary program that allowed users to draw geometric shapes directly onto a screen using a light pen, effectively transforming the computer into a design tool. Dr. Sutherland's work demonstrated the potential of computers in the design process and earned him recognition as one of the fathers of computer graphics. Alongside Sutherland, key individuals such as Dr. Patrick J. Hanratty, often referred to as the "Father of CAD," contributed significantly with his development of PRONTO, the first commercial numerical control programming system. Companies like Control Data Corporation, General Motors, and Lockheed also played pivotal roles in advancing CAD technologies. The innovations at Xerox PARC (Palo Alto Research Center) were particularly significant, as they introduced concepts such as the graphical user interface (GUI), object-oriented programming, and high-resolution bitmapped displays. These advancements greatly influenced the development of more user-friendly and powerful CAD systems, setting the stage for widespread adoption in various industries.

Early Applications and Limitations

The initial adoption of CAD tools was primarily within large aerospace and automotive companies, where the complexity of projects necessitated more advanced design methods. For instance, companies like Boeing and Ford utilized early CAD systems to design aircraft components and vehicle parts, enabling more precise specifications and detailed engineering drawings. However, these early CAD systems were limited by the computing power of the time. Mainframe computers, which were expensive and less accessible, powered these systems, and the software capabilities were relatively basic compared to modern standards. Users faced several challenges:

- Limited processing speeds and memory capacity.

- Minimal graphical displays with low resolution.

- Lack of interoperability between different CAD systems.

- Steep learning curves due to complex interfaces.

Additionally, there was resistance in user adoption due to the reluctance to deviate from established manual drafting workflows. Integrating CAD into traditional engineering processes required significant changes in organizational practices and substantial investment in both hardware and training.

Revolutionizing Complex Project Design

The introduction of CAD tools revolutionized the design of complex engineering projects by providing engineers with powerful capabilities for visualization, modeling, and analysis. CAD software introduced new possibilities for creating detailed and accurate designs that were not feasible with manual drafting methods. Engineers could now easily modify designs, explore alternative solutions, and detect potential issues early in the development process. The aerospace industry, for example, benefited immensely as CAD allowed for the intricate design of aircraft structures and systems with improved precision. The ability to create three-dimensional models enabled a more comprehensive understanding of the design, facilitating better decision-making and innovation. CAD tools also enhanced the development of complex products by supporting simulation and optimization, leading to higher quality and performance.

Collaboration and Interdisciplinary Integration

One of the significant impacts of CAD technology was its role in fostering collaboration among different engineering disciplines. CAD systems provided a common platform where mechanical, electrical, and civil engineers could work together more efficiently. This integration improved communication and data sharing, which was particularly important in large-scale projects involving multiple stakeholders. The ease of sharing digital files reduced miscommunications and errors that often occurred with manual drawings. Furthermore, CAD enabled the use of standardized components and practices across various departments and teams, streamlining the design process. Collaborative features in CAD software allowed for concurrent engineering, where multiple engineers could work on different aspects of a project simultaneously, significantly reducing development time.

Advancements in Precision and Efficiency

CAD dramatically improved precision in engineering drawings and calculations. The software's ability to handle complex geometries and perform accurate computations eliminated many errors associated with manual drafting. Features like dimensioning, tolerancing, and automatic scaling ensured that designs met exact specifications. Additionally, CAD software automated many repetitive tasks, such as creating standard components or generating bills of materials, which increased efficiency and allowed engineers to focus on more critical aspects of design. The reduction in design and development time led to significant cost savings for companies. CAD also facilitated easier documentation and revision control, ensuring that changes were tracked and the most up-to-date information was available to all team members.

Hardware and Software Innovations

The transition from mainframe computers to personal computers had a profound impact on the accessibility of CAD. In the early days, CAD systems ran on expensive and bulky mainframes, limiting their use to large organizations with substantial resources. However, the advent of personal computers in the 1980s democratized access to computing power. Companies like IBM and Apple played critical roles in this transition by providing affordable hardware capable of running CAD software. Advances in graphic capabilities and user interfaces also expanded adoption. Notably, developments included:

- Introduction of graphic display terminals with higher resolutions.

- Development of the graphical user interface (GUI) for easier interaction.

- Improved input devices like the mouse and digitizing tablets.

- Enhanced processing power and memory capacity in personal computers.

Software companies like Autodesk emerged during this period, releasing products like AutoCAD in 1982, which became widely adopted due to its compatibility with personal computers and relatively lower cost. These innovations made CAD tools more accessible to smaller firms and individual practitioners, broadening the impact of CAD across various sectors.

Emerging Trends and Technologies

The incorporation of parametric and solid modeling techniques marked a significant evolution in CAD technology. Parametric modeling allowed designers to define dimensions and relationships between different parts of a model, enabling easy modifications and updates. Solid modeling provided a complete representation of objects, supporting more accurate simulations and analyses. Companies like PTC introduced parametric, feature-based modeling software with the release of Pro/ENGINEER in the late 1980s. The role of Finite Element Analysis (FEA) and simulation became increasingly important in complex engineering projects. CAD software integrated FEA capabilities, allowing engineers to perform stress analysis, heat transfer, and other simulations directly within the design environment. This integration facilitated early detection of potential issues and optimization of designs before physical prototypes were built.

Growth of Specialized CAD Solutions

The growth of specialized CAD solutions catered to the specific needs of various industries. In aerospace, software like CATIA, developed by Dassault Systèmes, became the standard due to its advanced surface modeling capabilities. The automotive industry also adopted specialized tools for vehicle design and manufacturing processes. In architecture, CAD software evolved to support building design and construction documentation, with programs like ArchiCAD and later Building Information Modeling (BIM) tools like Revit becoming prevalent. The expansion into fields such as industrial design introduced tools that focused on aesthetics and ergonomics, supporting designers in creating consumer products with complex shapes and forms. This specialization allowed for more tailored solutions that addressed the unique challenges of different engineering disciplines.

Ongoing Impact on Engineering Practices

The early CAD tools set the stage for modern engineering methodologies by establishing the foundation for digital design and manufacturing processes. The principles of CAD integrated into engineering education, with universities incorporating CAD courses into their curricula, ensuring that new engineers are proficient in these essential tools. In contemporary engineering practice, CAD remains indispensable, enabling the development of increasingly complex and innovative products. The methodologies introduced by early CAD systems, such as parametric modeling and integrated analysis, continue to evolve, driving improvements in design quality and efficiency. The digital models created in CAD systems serve as the basis for manufacturing processes, including CNC machining and additive manufacturing, linking design directly to production.

Looking Forward: Innovations on the Horizon

The influence of emerging technologies like artificial intelligence (AI) and cloud computing is shaping the future of CAD tools. AI has the potential to automate routine tasks further and provide design recommendations, optimizing the engineering process. Machine learning algorithms can analyze large datasets to identify patterns and suggest improvements or predict potential issues. Cloud computing enables collaborative design across different locations, with real-time updates and access to powerful computing resources without significant investment in hardware. Software-as-a-Service (SaaS) models allow for scalable solutions that can be tailored to the needs of organizations of all sizes. These innovations may lead to shifts in engineering design processes and project management, with a greater emphasis on collaboration, flexibility, and integration of multidisciplinary teams.

Conclusion

The transformative role of early CAD tools in facilitating complex engineering projects cannot be overstated. From the visionary work of pioneers like Dr. Ivan Sutherland to the widespread adoption across various industries, CAD has revolutionized the way engineers design, analyze, and communicate their ideas. The legacy of these early innovations continues to influence contemporary practices, with ongoing advancements promising to drive further evolution in the field. As technology progresses, CAD remains a cornerstone in engineering and design, embodying the relentless pursuit of efficiency, precision, and innovation that defines the discipline.

Also in Design News

Rhino 3D Tip: Manage Rhino History: Disable, Lock, or Purge After Committing Geometry

February 10, 2026 2 min read

Read More

Cinema 4D Tip: Irradiance Cache Tuning for Fast, Stable GI in Cinema 4D

February 10, 2026 2 min read

Read More

V-Ray Tip: Disable Region Feathering for Seamless V-Ray Patch Renders

February 10, 2026 3 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …