Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

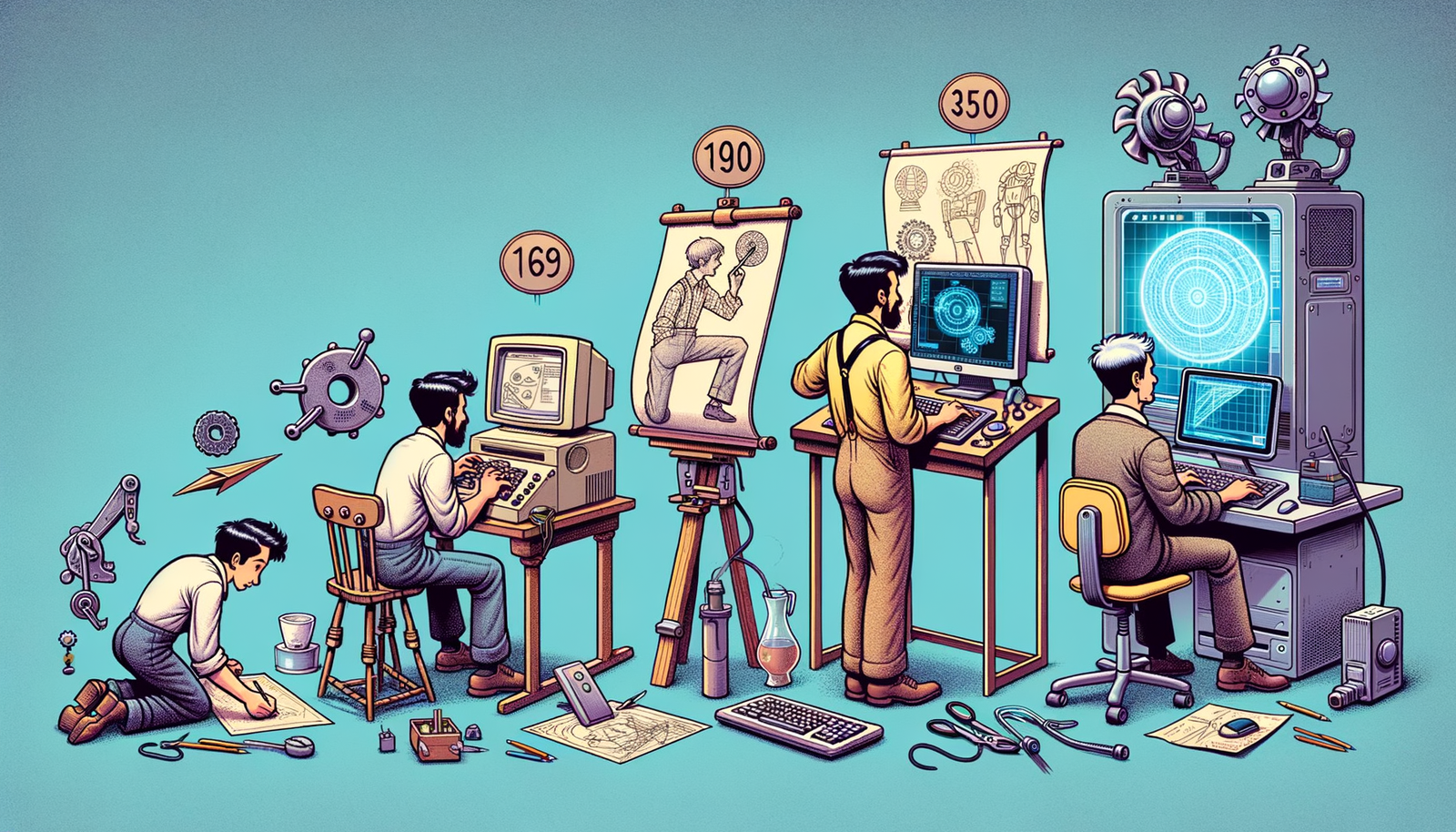

Design Software History: Evolution of CAD: From Sketchpad to Pro/ENGINEER and Beyond

July 08, 2024 5 min read

The Early Days of CAD - From Sketchpad to Pro/ENGINEER

Introduction to CAD

Before the advent of Computer-Aided Design (CAD) systems, the design processes relied heavily on manual drafting and physical prototypes. Engineers and designers used drafting tables, compasses, protractors, and other manual tools to create precise diagrams and blueprints. This meticulous and time-consuming process was prone to errors and required considerable skill and experience.

The significance of Ivan Sutherland's Sketchpad in 1963 cannot be overstated. Sutherland's Sketchpad was the world's first CAD system, introducing the concept of directly interacting with a computer to create drawings. It allowed users to draw on a CRT monitor with a light pen, and for the first time, designs could be created and manipulated digitally. Sketchpad's importance lies in its pioneering user interface and its foundational role in the development of interactive computer graphics.

Development of Early CAD Systems

The initial forays into CAD development saw significant contributions from various entities. Large corporations like General Motors introduced their own CAD systems, notably the DAC-1 (Design Augmented by Computer), which enabled engineers to create 2D designs more efficiently. Similarly, McDonnell Douglas developed its CADD (Computer-Aided Design and Drafting) system to enhance aerospace design and drafting capabilities.

In parallel, academic institutions were making substantial contributions. MIT's Project MAC (Multiple Access Computing) played a crucial role in advancing CAD technologies. Researchers at MIT, including Steven Coons, made early strides in developing mathematical models for computer graphics and CAD, laying the groundwork for future systems.

Transition to 3D Modeling

As CAD technologies progressed, the industry transitioned from 2D drafting to 3D modeling, significantly enhancing design capabilities. Early systems such as the 3D wireframe model enabled more complex visual representations of objects. However, 3D wireframe models had limitations, such as the inability to accurately represent internal structures and complexities of solid objects.

The Birth of Solid Modeling - A Game-Changer in CAD

Pioneers of Solid Modeling

The advent of solid modeling marked a revolutionary leap in CAD. Solid modeling allowed for the accurate representation of the volume and mass properties of objects, which was a game-changer for engineering and design. Early systems such as SynthaVision and BUILD were among the pioneers in this field.

Key figures in the development of solid modeling include Herbert Voelcker and Bruce Baumgart. Voelcker's work on mathematical models of solid objects and Baumgart's contributions to geometric modeling were instrumental in advancing the technology. Their research laid the foundation for robust solid modeling systems that would soon emerge.

Boundary Representation (B-Rep) and Constructive Solid Geometry (CSG)

Solid modeling primarily utilizes two approaches: Boundary Representation (B-Rep) and Constructive Solid Geometry (CSG).

- B-Rep: This approach represents the shape of a solid object using its surface boundaries. It defines the object by its vertices, edges, and faces, making it suitable for complex geometries.

- CSG: Constructive Solid Geometry builds complex objects by combining simple primitives like spheres, cylinders, and cubes using Boolean operations (union, intersection, and difference).

Early software utilizing these techniques included systems like PADL-1 (Part and Assembly Description Language), which helped engineers create detailed solid models for various applications.

Impact on Design and Engineering

Solid modeling transformed product design and simulation by allowing engineers to visualize and analyze objects with unprecedented precision. It facilitated more accurate simulations of physical properties, such as stress analysis and thermal dynamics, leading to better-engineered products. Industries such as automotive, aerospace, and consumer products were among the early adopters, recognizing the immense benefits of solid modeling in enhancing design and manufacturing processes.

Rise of Parametric and Feature-Based Design with Pro/ENGINEER

Introduction to Parametric Design

Parametric and feature-based modeling introduced a new paradigm in CAD systems, allowing for designs that could be easily modified and updated. Parametric design uses parameters and constraints to define the geometry of a model, enabling designers to make changes dynamically without having to redraw the entire design.

Parametric Technology Corporation (PTC) revolutionized the industry with the release of Pro/ENGINEER in 1988. This groundbreaking software brought parametric and feature-based design to the forefront, setting new standards for CAD systems.

Innovative Features of Pro/ENGINEER

Pro/ENGINEER introduced several innovative features that set it apart from existing systems:

- Parametric Constraints: Users could define relationships between different parts of the model, ensuring that changes to one part would automatically update related parts.

- Feature-Based Design: Designers could create models using high-level features such as holes, fillets, and chamfers, streamlining the design process.

- Assembly Modeling: Pro/ENGINEER's robust assembly modeling capabilities allowed for the creation of complex assemblies with numerous components.

These functionalities provided significant competitive advantages, making Pro/ENGINEER a preferred choice for many industries.

Industry Adoption and Influence

Pro/ENGINEER's impact on the aerospace, automotive, and manufacturing industries was profound. Its adoption led to more efficient design processes, reduced time-to-market, and improved product quality. The success of Pro/ENGINEER also influenced subsequent developments in CAD software, pushing competitors to incorporate similar parametric and feature-based capabilities.

Modern CAD Systems and the Future of Design Software

Current State of CAD

Today, the landscape of CAD systems is dominated by several leading software solutions, each offering unique capabilities tailored to different industries and applications. Among the most prominent are:

- AutoCAD: A versatile and widely-used CAD software from Autodesk, known for its robust 2D drafting and 3D modeling capabilities.

- SolidWorks: A popular choice for mechanical design, offering powerful solid modeling and simulation tools.

- CATIA: Developed by Dassault Systèmes, CATIA is renowned for its advanced surface modeling and engineering capabilities, particularly in aerospace and automotive industries.

- Fusion 360: Autodesk's cloud-based CAD/CAM software that integrates CAD, CAM, and CAE functionalities, promoting collaboration and innovation.

The integration of CAD with CAM (Computer-Aided Manufacturing), CAE (Computer-Aided Engineering), and PLM (Product Lifecycle Management) systems has further enhanced the capabilities of modern design software, enabling seamless workflows from design to manufacturing.

Technological Innovations

The rapid advancement of technology continues to shape the future of CAD. Innovations such as cloud computing, artificial intelligence (AI), and machine learning are playing a pivotal role in enhancing design processes and capabilities.

The impact of VR/AR (Virtual Reality and Augmented Reality) on design visualization and collaboration is also significant. These technologies allow designers to immerse themselves in virtual environments, providing a deeper understanding of spatial relationships and design aesthetics. Collaboration is enhanced as team members can interact with digital models in real-time, regardless of their physical location.

Future Trends

Several emerging trends and technologies are poised to shape the future of CAD:

- Predictive Maintenance: Leveraging real-time data and AI to predict equipment failures and maintenance needs, improving reliability and reducing downtime.

- Generative Design: Using algorithms to generate optimized design solutions based on specified parameters and constraints, leading to innovative and efficient designs.

- Digital Twins: Creating digital replicas of physical objects or systems for real-time monitoring, simulation, and optimization.

As these technologies continue to evolve, their integration with CAD systems will drive further advancements in design, engineering, and manufacturing, opening new possibilities for innovation and efficiency.

Also in Design News

Rhino 3D Tip: Configure Document Units and Tolerances Before Modeling

February 19, 2026 2 min read

Read More

Design Software History: From Sketchpad to Node Graphs: A Technical History of Constraint and Visual Design Software

February 19, 2026 15 min read

Read More

Unified Structural, Thermal, and Cost Optimization: MDO Architecture, Algorithms, and Governance

February 19, 2026 12 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …