Your Cart is Empty

Get a Personalized Quote×

SpinFire Insight is an enterprise-grade 3D and 2D CAD viewer designed to bring consistent, organization-wide access to CAD information without requiring every stakeholder to have a CAD authoring license. Built on the proven SpinFire technology trusted by automotive and industrial leaders for more than 25 years, SpinFire Insight gives engineering-adjacent teams the ability to open, inspect, measure, and understand complex parts, assemblies, and drawings in a single, uniform environment. From manufacturing and quality to purchasing, sales, marketing, and suppliers, it helps everyone work from the same visual truth—reducing misunderstandings, shortening feedback cycles, and enabling faster decisions across the product lifecycle.

At its core, SpinFire Insight is about turning CAD files into actionable, shareable information. Users can interrogate geometry, evaluate key physical properties such as volume, surface area, weight, and center of mass, and perform precision measurements to validate design intent and manufacturing feasibility. Powerful tools like sectioning, analysis, and comparison make it easy to uncover details that would otherwise stay locked inside specialized CAD systems. With multi-CAD support, teams can collaborate across file types and suppliers, while staying aligned on revisions and change requests.

SpinFire Insight is also engineered for usability at scale. An intuitive interface, available in more than 10 languages, helps standardize reviews and communication across global teams. Whether you’re reviewing an exploded assembly, checking wall thickness, validating draft angles, or annotating a model for a design discussion, SpinFire Insight streamlines the path from CAD data to informed action—helping enterprises move faster, with greater clarity and confidence.

| Communicate with Clear, CAD-Based Feedback SpinFire Insight improves productivity by making CAD information instantly accessible to the people who need it most, even when they are not CAD specialists. Instead of relying on screenshots, lengthy email chains, or ambiguous descriptions, stakeholders can review parts and assemblies directly and provide feedback tied to the actual geometry. This reduces misinterpretation and accelerates decision-making during reviews, change requests, and approvals. The experience is designed to be approachable: the interface is intuitive and available in more than 10 languages, which helps organizations standardize how teams interact with CAD across regions and departments. When teams can see the same model, ask better questions, and document changes more clearly, engineering time is protected and downstream work is less likely to be disrupted by misunderstandings.

|  |

| Collaborate Across Teams and CAD Systems Modern product development rarely happens inside one department or one CAD format. Suppliers, partners, and internal teams often work with different authoring tools, which makes file sharing and review workflows more complex than they need to be. SpinFire Insight is built for multi-CAD enterprise collaboration, enabling users to view and share CAD data across internal and external teams—whether they are at the office, at home, or on the road. By providing a consistent viewer environment, SpinFire Insight reduces friction in cross-team discussions and helps stakeholders focus on the decision at hand rather than the tooling required to open a file. It also supports collaborative workflows by making it easier to distribute CAD information broadly, allowing more contributors to provide input earlier—when changes are cheaper and schedules are easier to protect.

|  |

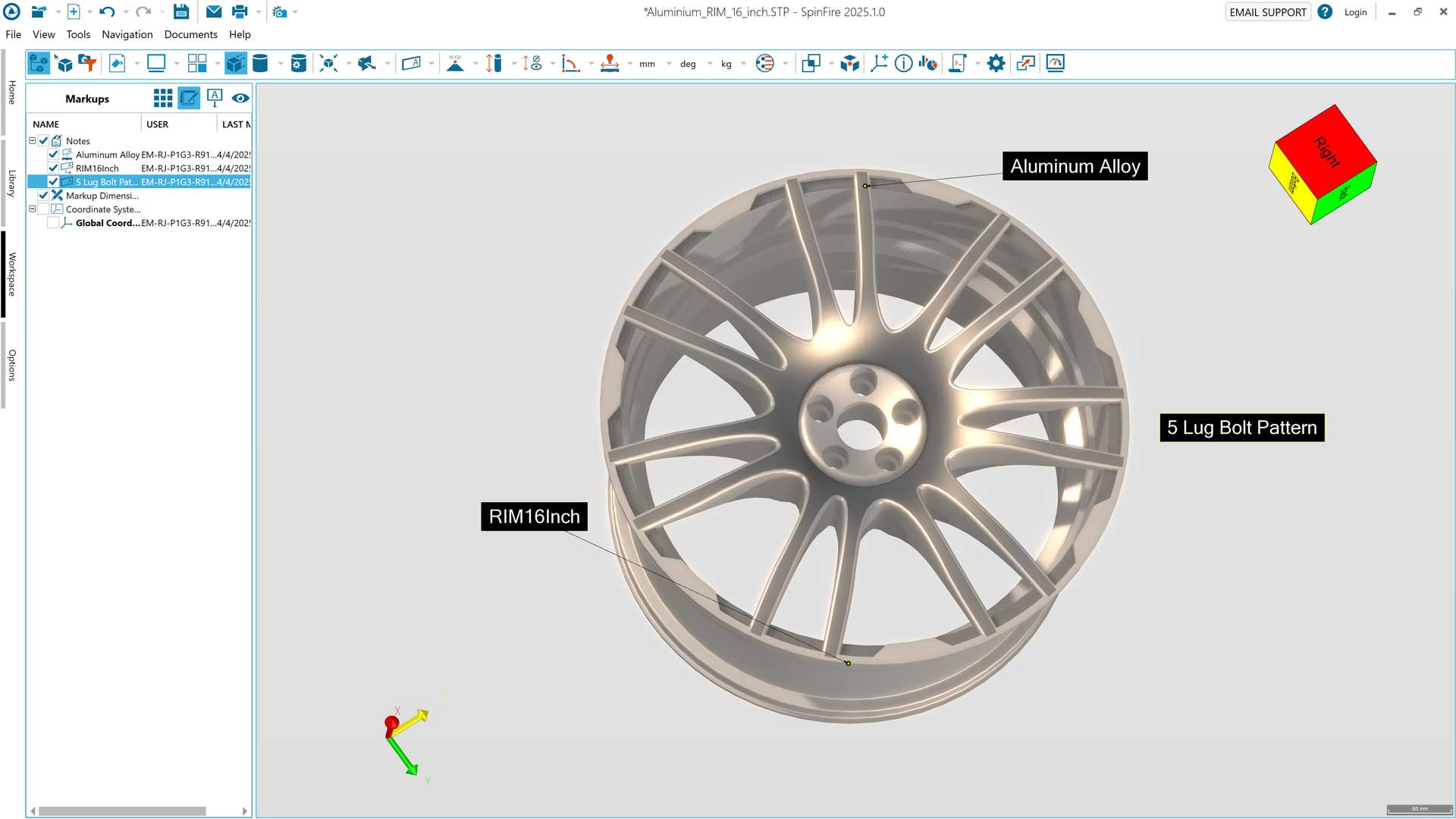

| Comprehend Products Faster with Visual Context SpinFire Insight transforms how organizations understand products by putting “pictures to part numbers.” This capability is especially valuable outside the core engineering team, where decisions often depend on grasping what a component is, how it fits into an assembly, and what design intent it supports. When managers, sales teams, marketing, purchasing, quality, and vendors can clearly see the product structure, they can move faster and make smarter decisions—without waiting for engineering to translate CAD details into simplified formats. The benefit is not only speed; it is consistency. Everyone gains access to the same visual source of truth, which reduces the risk of decisions being made on outdated drawings, incomplete screenshots, or secondhand interpretations. For organizations scaling product lines or managing complex configurations, this shared comprehension is a practical advantage that improves alignment and execution.

| |

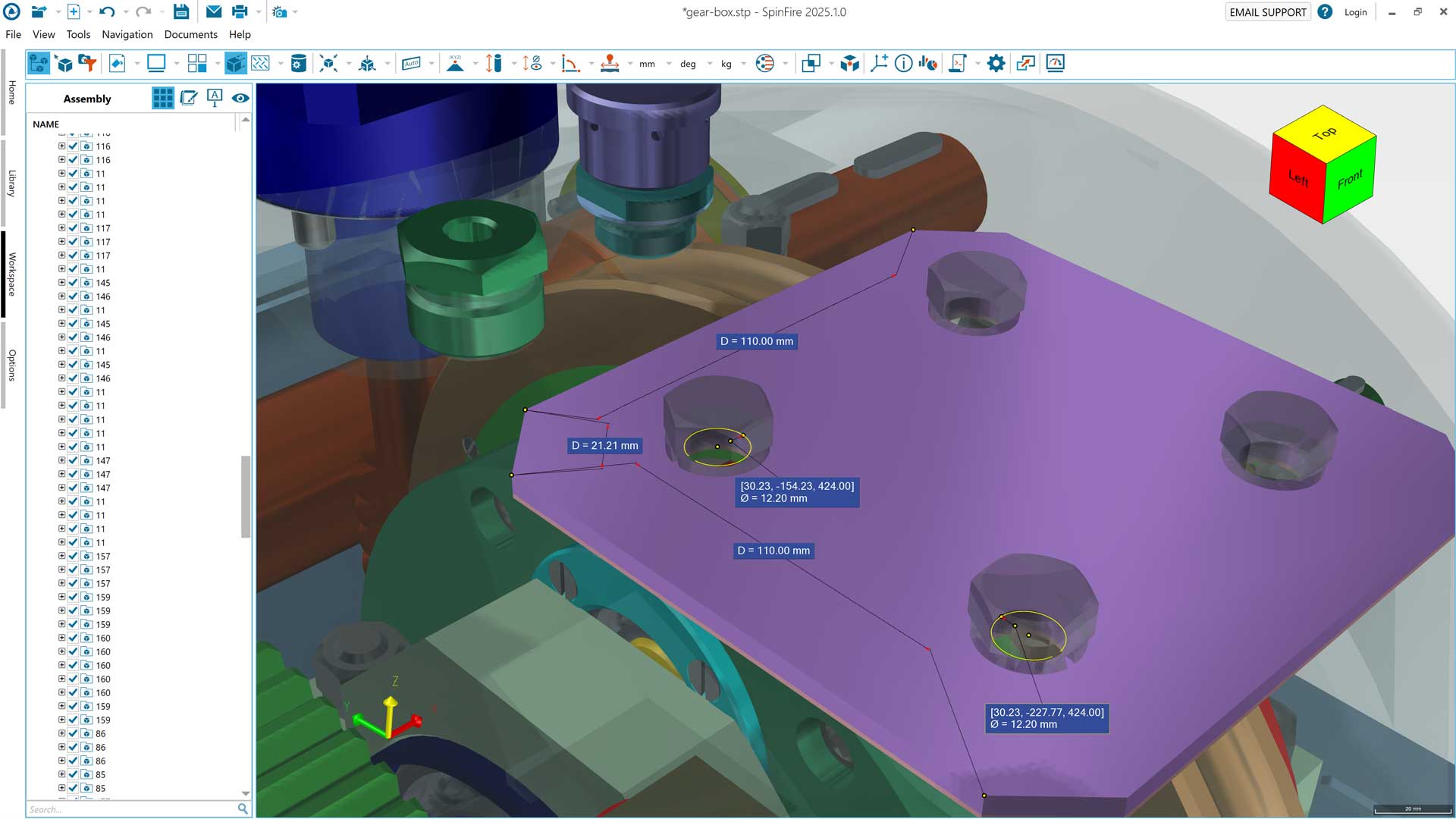

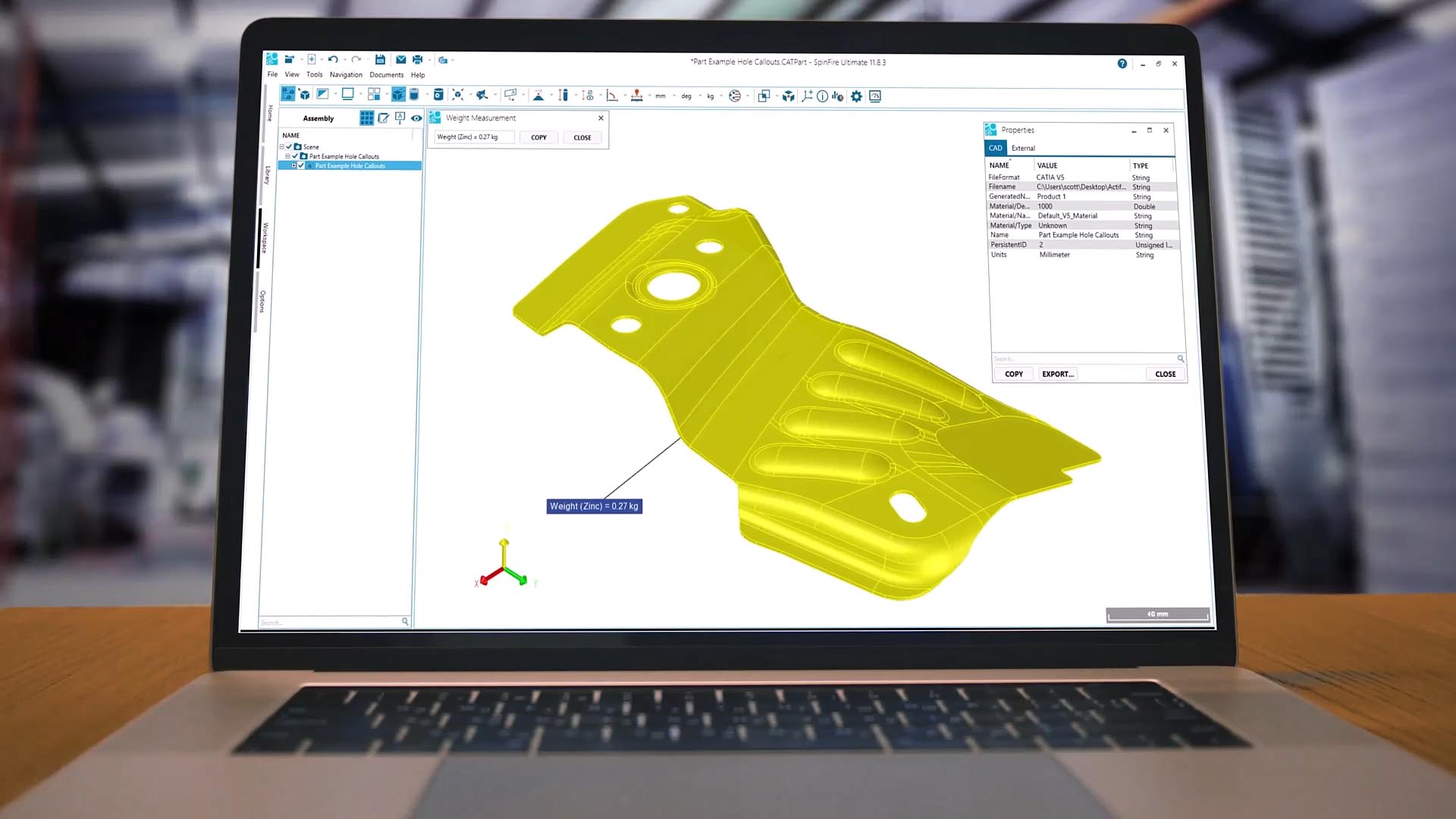

| Comprehensive Interrogation, Measurement, and Analysis Tools SpinFire Insight equips teams with professional-grade tools to inspect and interrogate CAD data with confidence. Beyond simply opening files, users can evaluate assemblies and parts using features that help answer real questions: What changed between revisions? Is there adequate wall thickness? Are draft angles suitable for molding? What is the minimum distance between critical surfaces? These capabilities support better engineering-adjacent decisions and faster iteration cycles. The platform also provides insight into core properties such as volume, weight, surface area, and center of mass, which can help teams validate design assumptions, evaluate manufacturability, and improve planning. Users can also calculate edge-based results, such as the sum of connected edges selected or the area defined by those edges, making it easier to derive actionable measurements from complex geometry without switching tools.

|  |

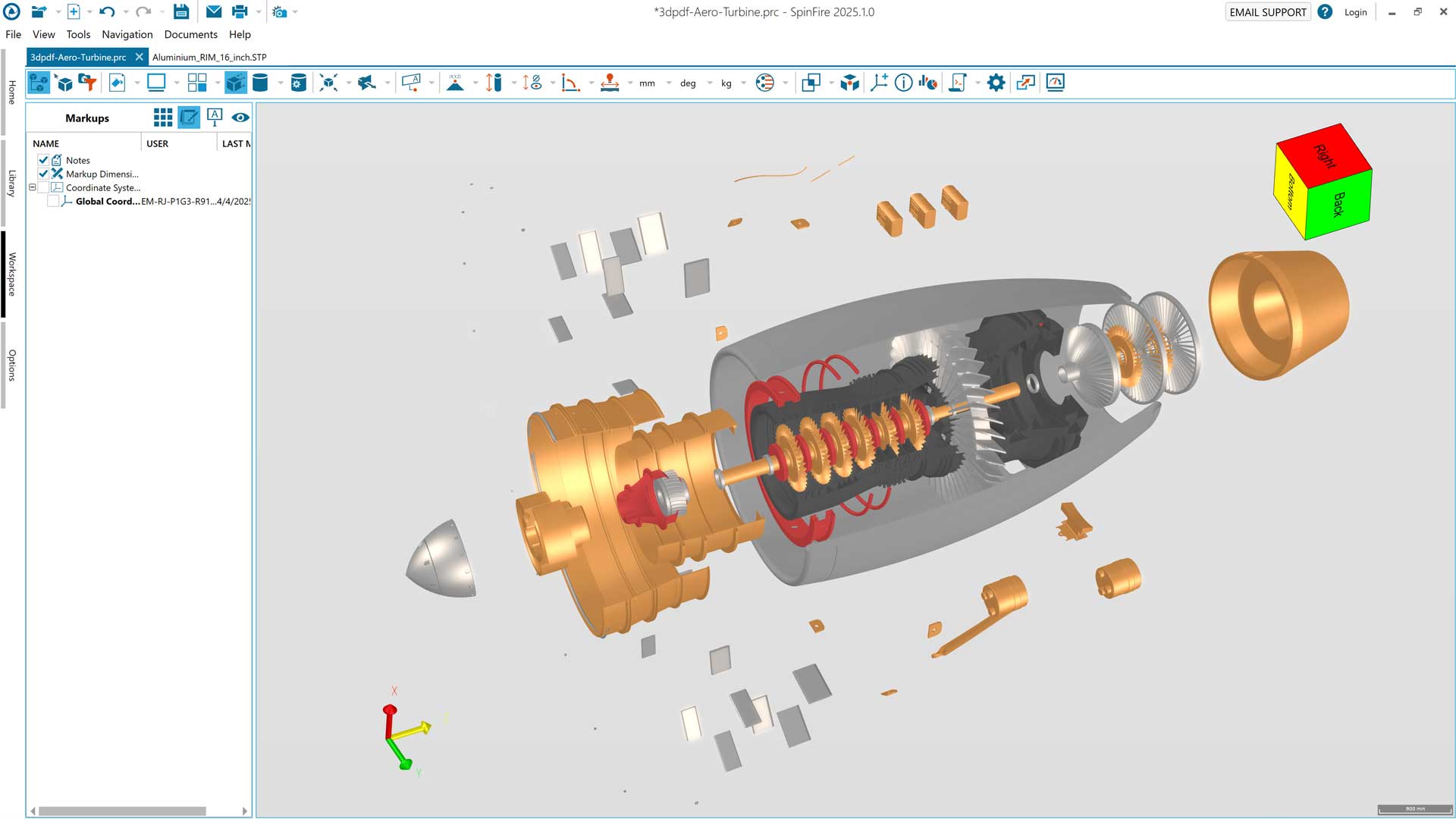

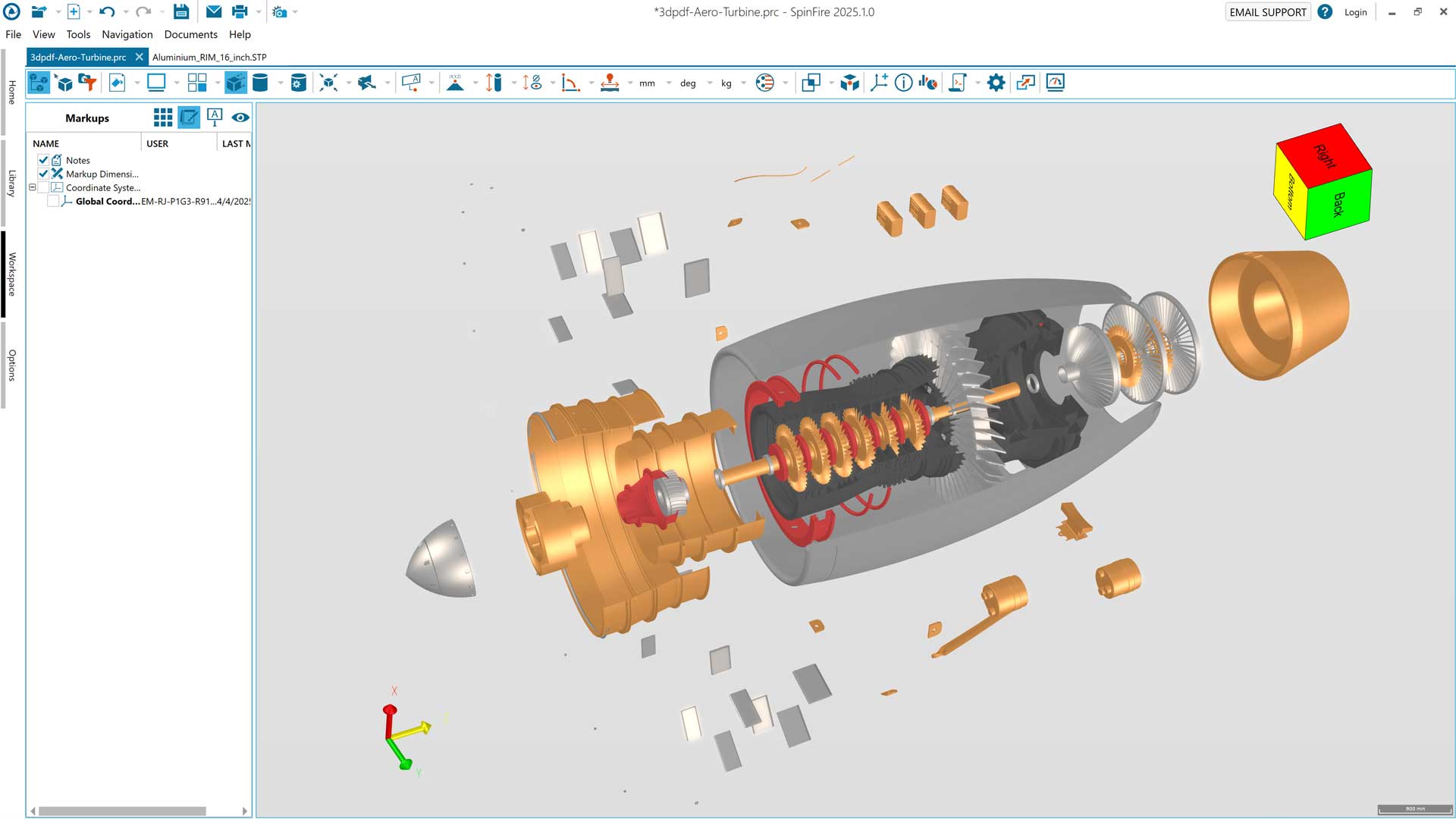

| Exploded Assembly for Fast Structure Reviews The Exploded Assembly feature helps teams understand product structure by transforming multiple—or all—parts of an assembly in a chosen, uniform pattern. This is especially useful when reviewing complex designs where internal relationships and part ordering are difficult to interpret in a standard assembled view. By separating components cleanly, stakeholders can validate assembly intent, identify interferences conceptually, and communicate about specific parts without confusion. Exploded views are also valuable for training, documentation, manufacturing planning, and service discussions, where understanding what goes where is more important than editing geometry. In SpinFire Insight, this capability supports faster meetings and more precise conversations because it turns an intricate assembly into a clear, navigable visual breakdown. The result is improved clarity for both technical and non-technical users reviewing the same dataset. |  |

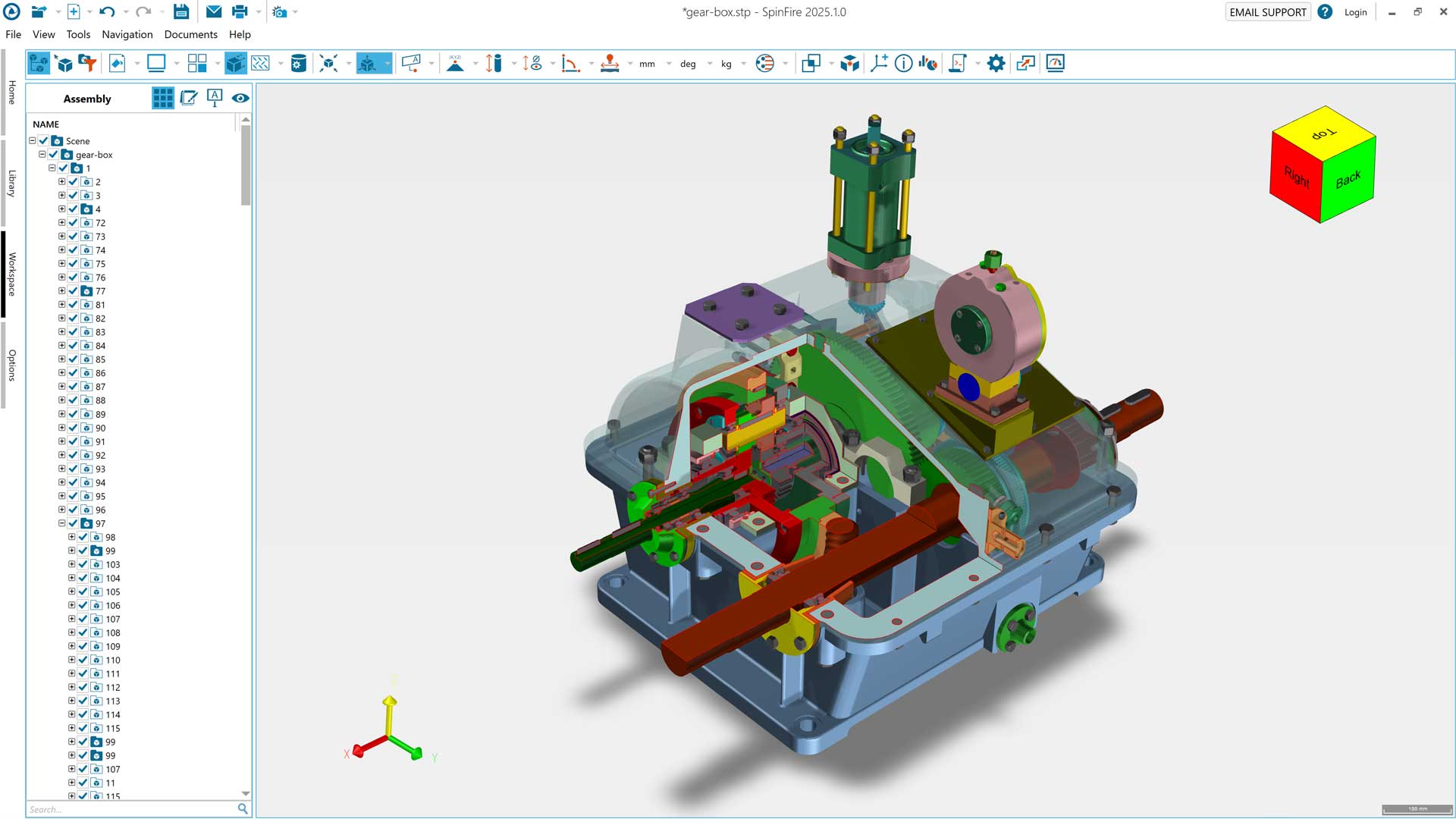

| Section Cut to Reveal Internal Geometry With Section Cut, users can slice through 3D models to reveal hidden internal geometry for clearer analysis and review. This is essential when evaluating parts with internal channels, cavities, ribs, and nested components that are not visible from the outside. Sectioning improves understanding during design reviews, manufacturing planning, and quality investigations by letting teams examine what is happening inside the product without needing the original CAD authoring system. It also supports more accurate conversations about fit, clearance, and internal architecture, which can reduce rework caused by unseen constraints. For stakeholders who must validate the manufacturability or serviceability of a design, section cuts offer a direct way to confirm what’s possible and what may need adjustment. The result is faster insight, fewer assumptions, and more confident decisions across the enterprise. |  |

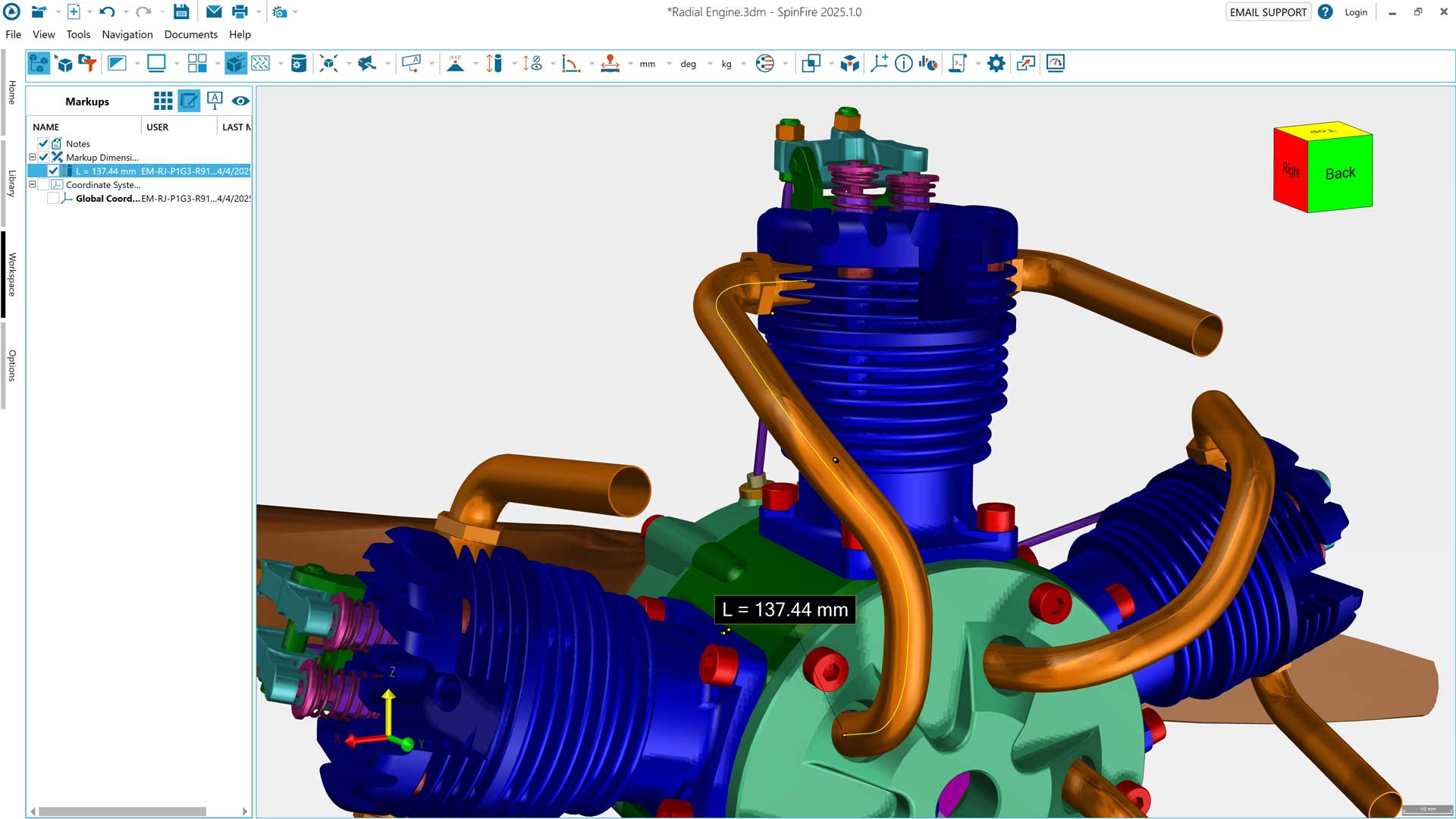

| Smart Dimensioning and Markup for Review Cycles SpinFire Insight supports practical review workflows with tools like Smart Dimensioning and Markup. Smart Dimensioning helps users generate accurate measurements quickly with intuitive, context-aware tools, enabling teams to validate distances and features during discussions without waiting on engineering to extract dimensions. Markup allows users to add comments, annotations, and highlights directly on models, turning reviews into documented, trackable communication. Together, these capabilities help reduce ambiguity and ensure that feedback is tied to the correct geometry and viewpoint. This is particularly valuable in cross-functional settings where multiple teams must agree on changes and where clarity prevents delays. Instead of translating requests into separate documents, teams can capture intent directly on the CAD view, supporting faster alignment and more reliable follow-through.

|   |

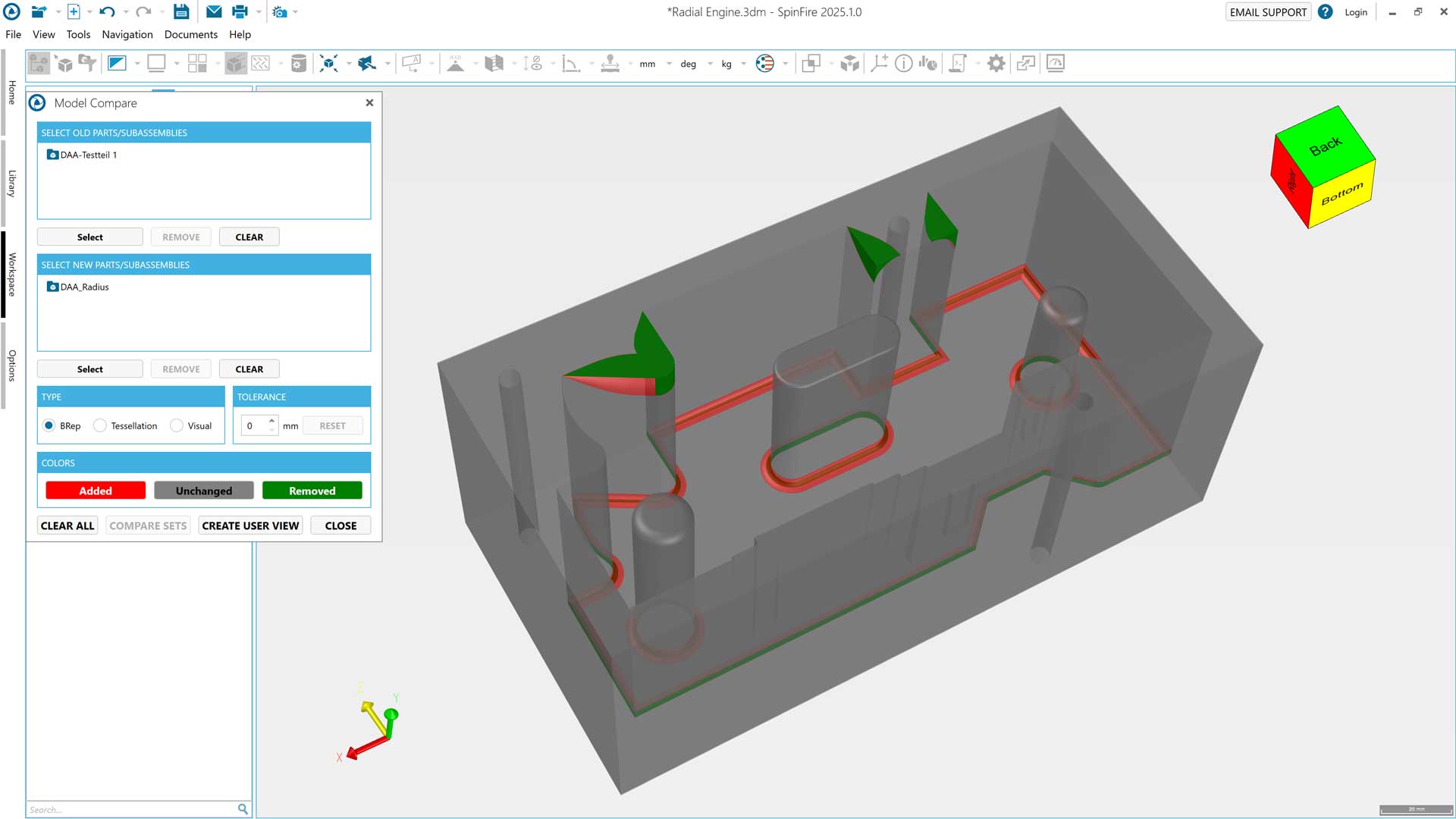

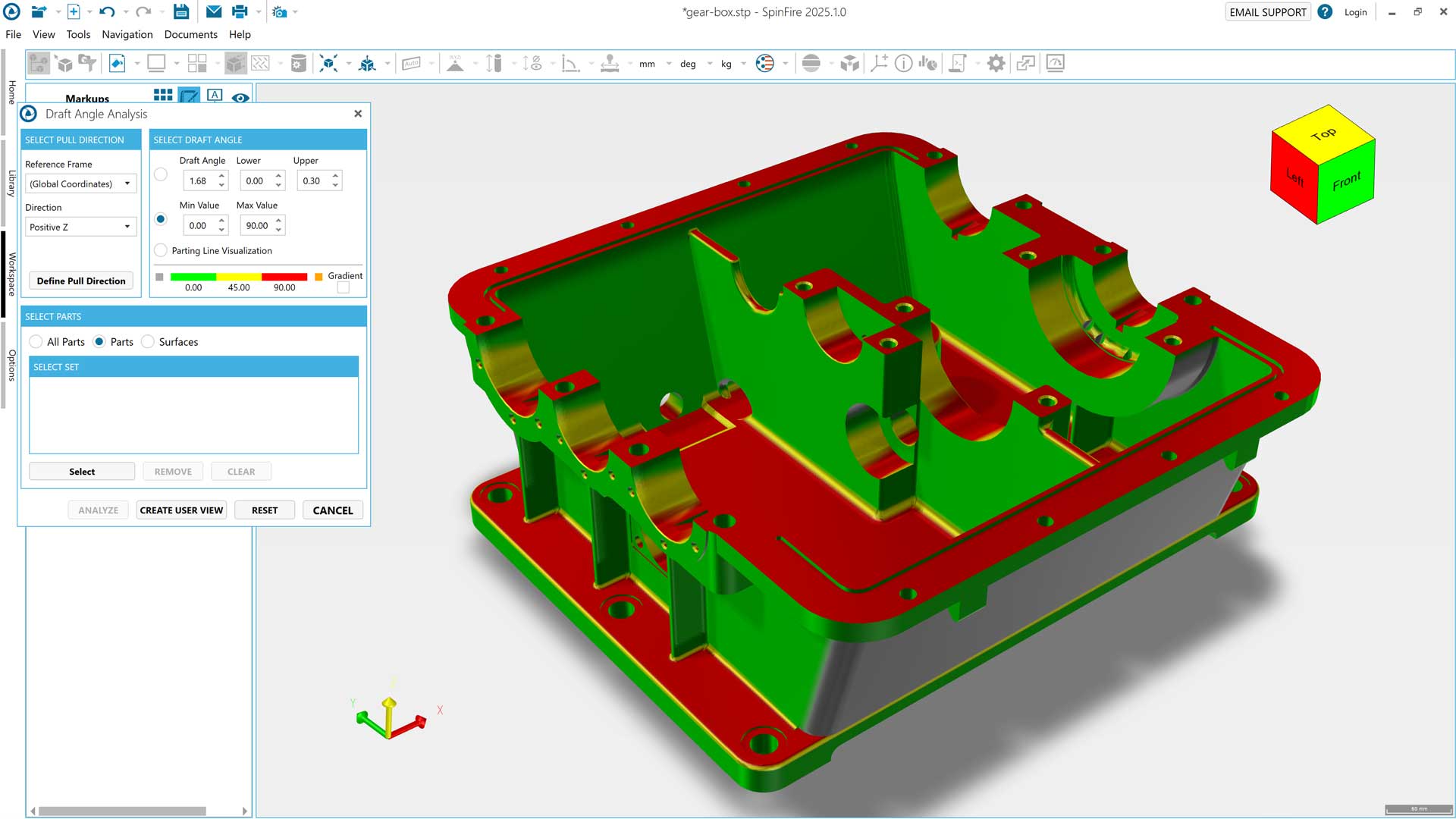

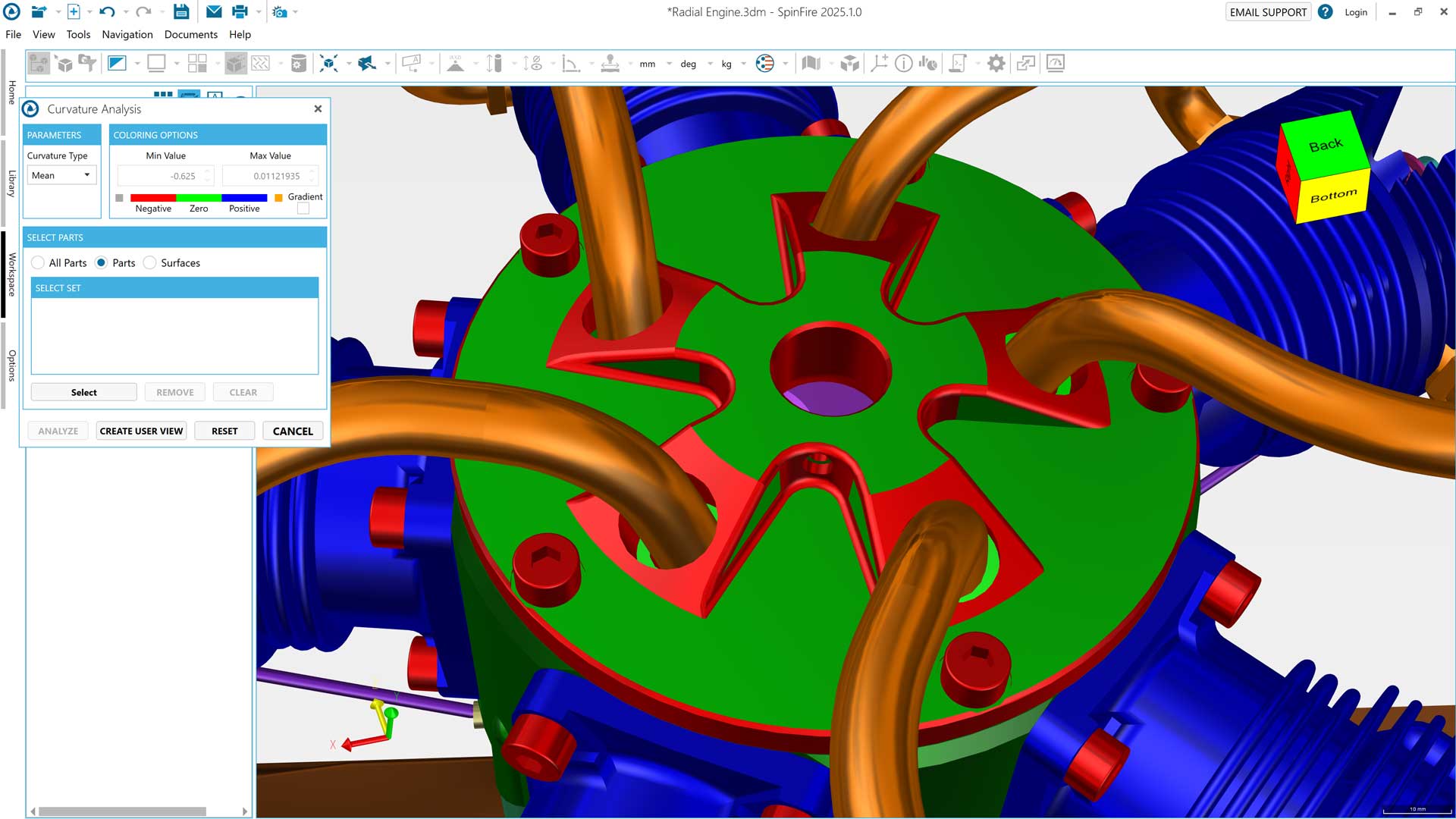

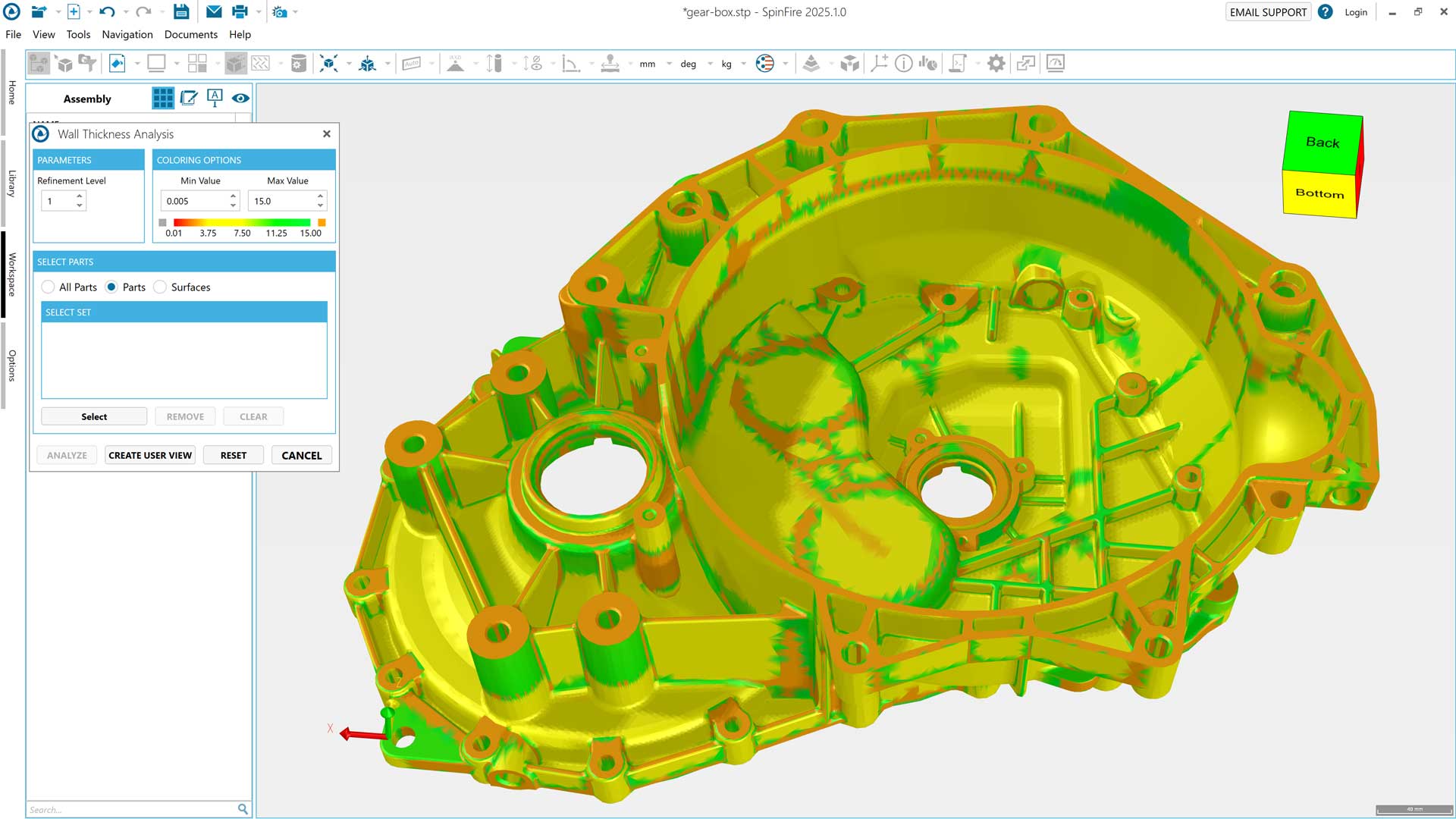

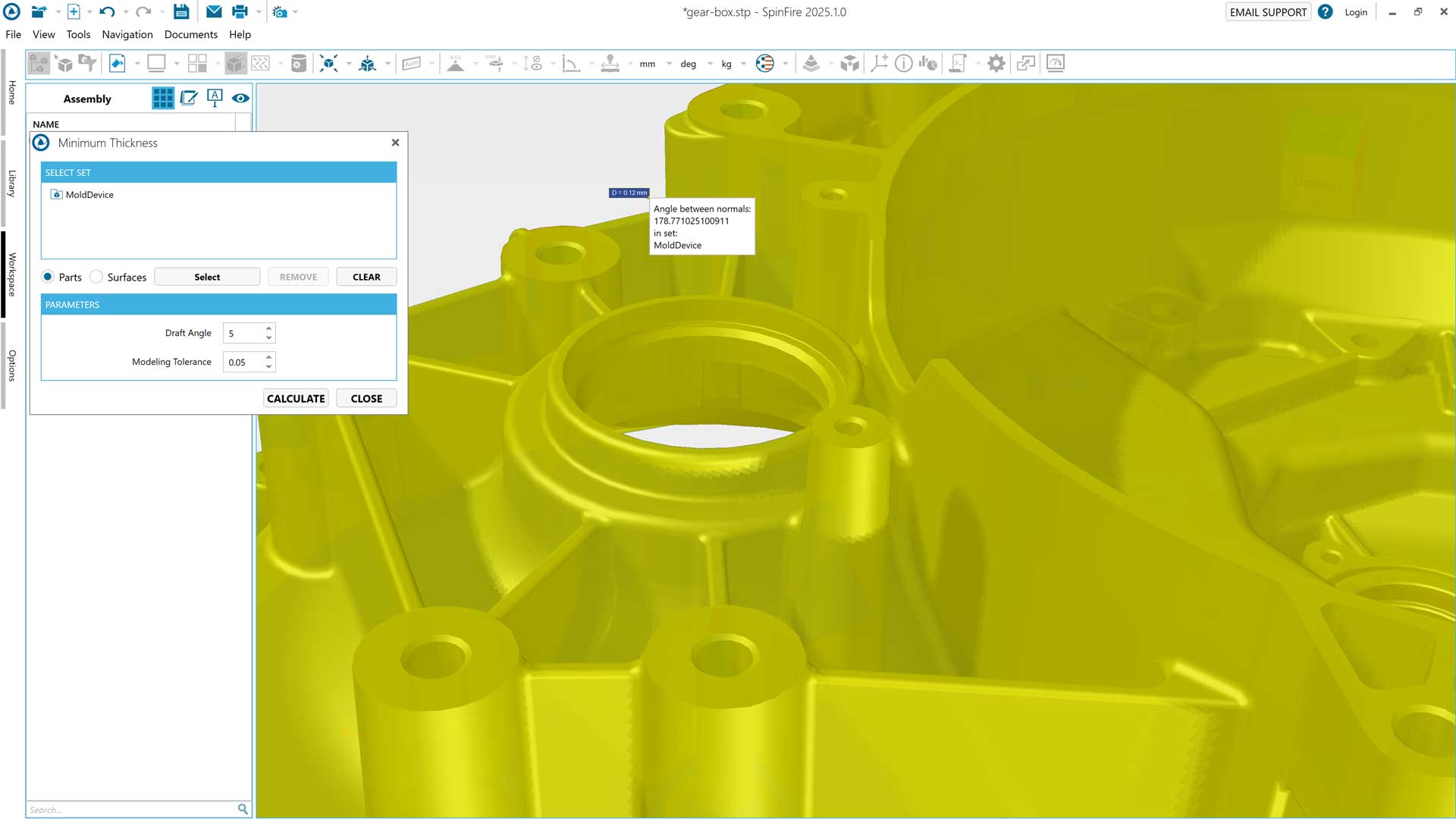

| Model Comparison and Manufacturability Checks SpinFire Insight includes tools that help teams detect changes and validate manufacturability quickly. Model Compare enables users to visually and numerically compare two CAD models to detect design changes and revisions—an essential capability for confirming what changed, supporting supplier communication, and reducing errors caused by working from mismatched versions. For manufactured parts, capabilities like Draft Angle Analysis, Curvature Analysis, and Wall Thickness Analysis help identify potential issues early. Draft angle evaluation supports molded and cast components by confirming that geometry can release from tooling. Curvature inspection helps ensure surface quality and design flow, and wall thickness analysis supports durability and defect reduction. These features provide quick, practical insight that helps teams move from “Is this ready?” to “What needs attention?” without delay.

|     |

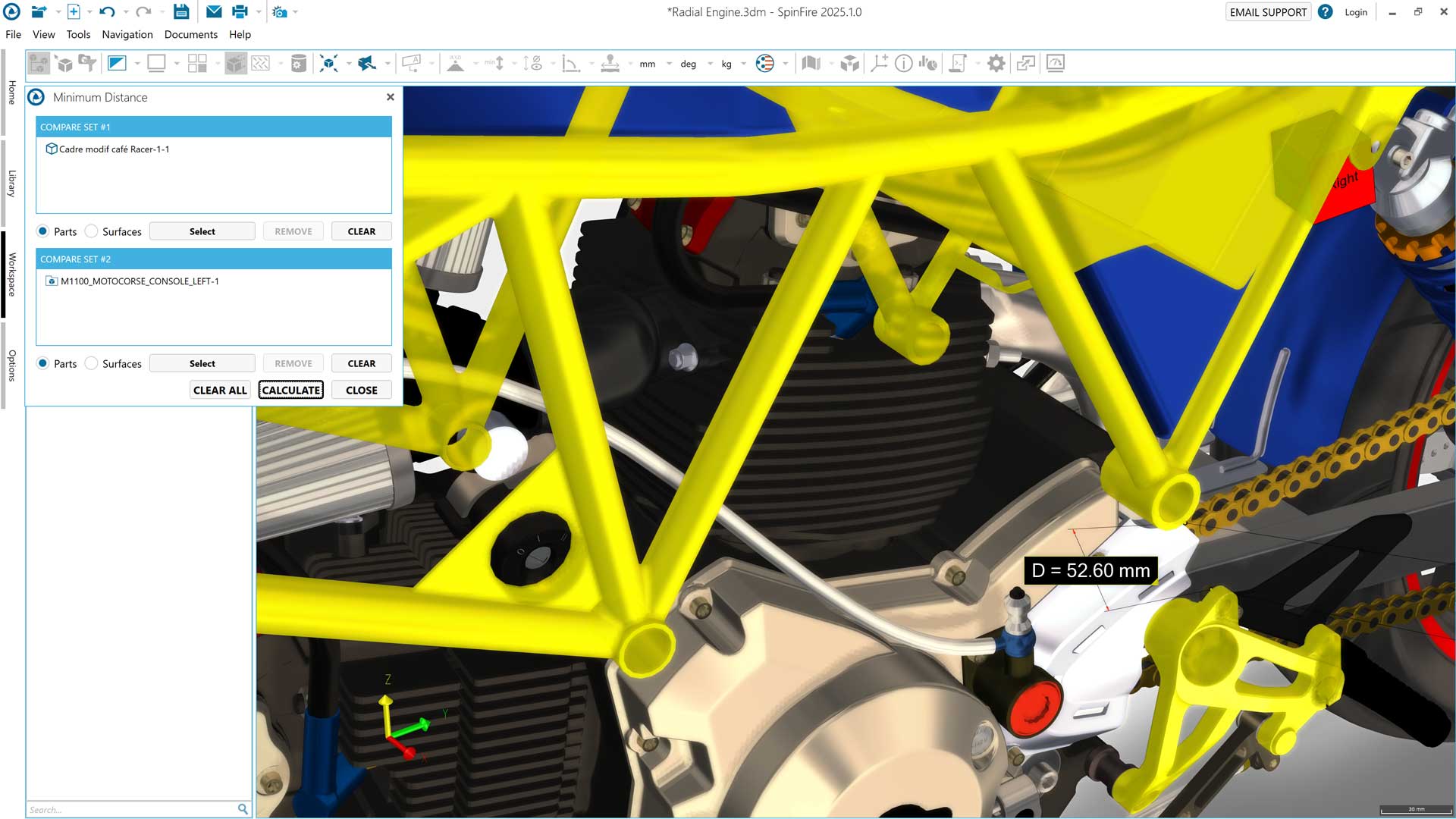

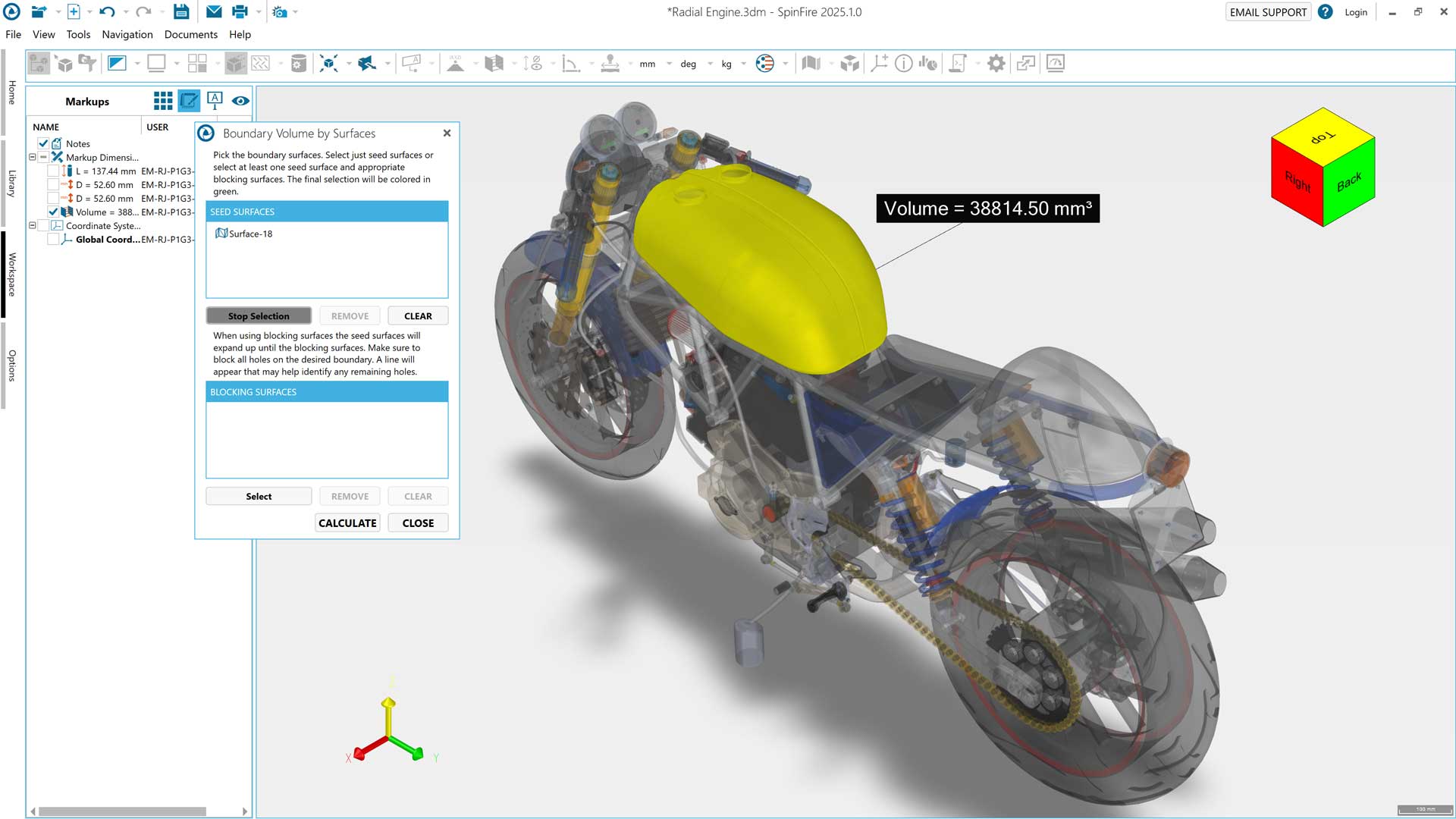

| Advanced Measurements: Distance, Thickness, Tube Length, and Boundary Volume For teams who need measurable answers—fast—SpinFire Insight provides advanced tools that go beyond basic point-to-point dimensioning. Minimum Distance measures the shortest distance between two sets of points or surfaces, supporting clearance checks and fit validation. Minimum Thickness calculates the minimum thickness across a selection, helping users evaluate structural reliability or manufacturability constraints. Tube Length automatically calculates tube and pipe lengths, simplifying manufacturing planning, cost estimation, and downstream documentation for routed components. Boundary Volume by Surface helps determine the volume of a model based on selected bounding surfaces, or measure the volume of a void created by a model—supporting packaging studies, capacity evaluation, and design verification. These capabilities bring engineering-grade insight to a wider audience, enabling better decisions without slowing teams down.

|     |

| Format-Neutral Viewing with Broad Multi-CAD Support SpinFire Insight is built to be format neutral, supporting all major 2D and 3D CAD formats so teams can work efficiently across suppliers and internal groups. Supported formats include CATIA V5, NX, Creo, SOLIDWORKS, Inventor, Solid Edge, as well as neutral and exchange standards such as STEP, JT, IGES, Parasolid, STL, and 3D PDF, among others. This flexibility helps enterprises reduce friction caused by heterogeneous CAD environments and enables fast, accurate viewing without requiring the original CAD application to be installed. The result is simpler collaboration, faster onboarding for stakeholders, and fewer delays caused by file compatibility challenges.

|  |