Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

The Edge: Samantha Snabes’s Giant 3D Printer

May 10, 2013 5 min read

Novedge: Tell us about yourself and what you do.

Samantha Snabes: I am the catalysts and co-founder of re:3D.

re:3D was founded in January 2013 by a team of six dynamic entrepreneurs with diverse professional backgrounds, yet united by one singular vision: to transform the tangible world through 3D printing. Our founders have more than 50 years of combined experience in engineering, manufacturing, tool and die, research and entrepreneurship.

Based in Austin, Texas, re:3D is committed to trailblazing new frontiers in 3D printing. Our flagship technology, the GigabotTM, is a high-performance, robust, affordable 3D printer with a build volume of 8 cubic feet — 30 times the build volume of a standard consumer device. re:3D is also at the forefront of material science, developing novel printer feedstocks including recycled plastics and enriched composites. With a global online marketplace and a localized presence in Latin America, re:3D is reaching untapped emerging markets worldwide.

Novedge: Why create a large-format 3D printer?

Samantha Snabes: The vast majority of home 3D printers have a build volume of less than 1 cubic ft, which limits the ability to create at human scale. GigabotTM enables printing in the 8 cubic ft range. Imagine household, industrial, and educational applications. For example, communities are already envisioning 3D-printed furniture, tools, decorative artwork, storage containers, and other functional objects. Architectural firms can now create in-house rapid prototyping at a larger, high-quality scale. Conversely, small production companies can now affordably complete in-house set design. Imagine a micro-entrepreneur in Latin America creating composting toilets and rainwater catchment systems for local sanitation and water conservation projects. Think big, print big.

Novedge: What software do you recommend for 3D printing with the Gigabot?

Samantha Snabes: With some general ideas of what 3D printing is your next step is to obtain a solid model or .stl file of the object you want to print. There are a number of places on the web where you can download models for printing or you can be creative and make your own models. One of the largest 3D model sites on the web is Thingiverse. There are many other sites as well. Some are tailored to specific markets such as video game design or architectural design.

Modeling the object can be done in a variety of modeling software. Some are free and others can cost tens of thousands of dollars. Google SketchUp is free and can be found here. There is an add-on to Google SketchUp that will export .stl files for 3D printing, download it here. Most any 3D modeling software will work if it can export a .stl file.

It is worth to note that sometimes you may receive a .stl file that is either downloaded or exported that has errors. The most common error is for the model to not be “water tight” or not manifold. If you can visualize a model that has a hole in the surface it would not hold water. For 3D printing the entire outside surface of the model must be completely closed with no holes. There are several ways to fix the .stl model. You can use a free online service called Netfabb cloud service that will automatically fix many problems with your .stl file: http://cloud.netfabb.com/. Netfabb offers stand-alone software that is free as well as a pro version you can buy that offers more features.

Once you have a .stl file that you are happy with the next step is to process or ‘slice’ the model and translate it into commands that drive the 3D printer. There are several free open source community developed software packages for slicing. The above RepRap newsletter is a great source for information on different slicing software. Slic3r is very popular software and there is a well written introduction to Slic3r here. The output from the slicing program is a .gcode file that is essentially a list of X, Y and Z coordinates that the printer reads for movement instructions.

The software, Pronterface, that we use to read the .gcode and move the printer is also open source and community developed can be found here. Before you receive Gigabot we will have even more instruction that will help familiarize you with Pronterface and Slic3r.

Novedge: What is your response to the critics who say that a 3D printer would not be helpful to people who lack access to food and basic sanitation?

Samantha Snabes: Modern society is facing complex, dynamic challenges that require solutions capable of spanning local needs with global demands. re:3D's vision is to harness the rapid growth potential of 3D printing technology to create employment opportunities and new end users in Latin America and other emerging markets. By leveraging relationships with local educational institutions, governments, non-profit organizations, and corporations, re:3D seeks to build communities around customized 3D printing solutions.

Also, the materials we use to create products defines the lifecycle of our economies. 3D printing opens new avenues for sourcing and producing objects that will reposition fabrication in a post industrial world. Recognizing this, re:3D is partnering on technologies to transform recycled materials into plastic filament. "3D re:purposing" will not only drive down input costs, but create new markets for recycled materials, thereby reducing landfill waste and resource depletion.

3D printing alone may not solve the multi-variable problem of global food security and sanitation, but it does have the potential to facilitate small steps as citizen scientists, problem solvers, and entrepreneurs we explore opportunities to improve the world around us.

Novedge: As the title of an article about you asked: "Will 3D printers save the world?"

Samantha Snabes: We believe that 3D printers have the potential to be adapted as enabling technologies to help contribute to solutions that improve life on earth.

Novedge: What is social entrepreneurship?

Samantha Snabes: This is a tough question. I wrote about this theme last year on open.nasa.gov. You can read my response here.

Novedge: What are some of the rewards and challenges of founding and being part of a start-up company?

Samantha Snabes: Any engineering endeavor is a balancing act between the opposing forces of physics: form vs. function; precision vs. speed; feature vs. necessity. Matthew Fiedler, Chief Hacker of re:3D, optimized Gigabot for performance and size at a highly affordable price point for serious hobbyists and small businesses alike.

A second obstacle has been maintaining effective lines of communication within a distributed team. The re:3D founders are currently spread across four distinct geographies: Austin, Texas; Santiago, Chile; Houston, Texas; and Syracuse, NY. We’ve overcome the distance by rigorously maintaining biweekly video chat tag-ups, and prioritizing face-to-face meetings whenever possible. We also leverage multiple communication channels including Google Hangouts, Skype chat, and e-mail.

Novedge: You received tremendous support on Kickstarter: what advice would you give to anyone looking into financing their project using that platform?

Samantha Snabes: Take advantage of local resources and timing opportunities. We were incredibly blessed to have the Start-Up Chile community behind our campaign and fortunate to be featured at the SXSW Interactive festival in re:3D’s backyard of Austin, Texas, the day we launched our campaign. Showcased at Startup Chile’s trade show booth, we ran a live demo of Gigabot printing in action for hundreds of SXSW participants. The demo generated significant buzz and media attention, which catapulted our Kickstarter campaign. In just 24 hours, Gigabot had met its Kickstarter goal, only to double it the following day.

Curious about re:3D? Visit their website.

Looking for a smaller 3D printer? Check out what Novedge has to offer here.

Related articles

Also in NOVEDGE Blog

Enhance Your Designs with VisualARQ 3: Effortless Geometry Extensions for Walls and Columns

April 30, 2025 8 min read

Read More

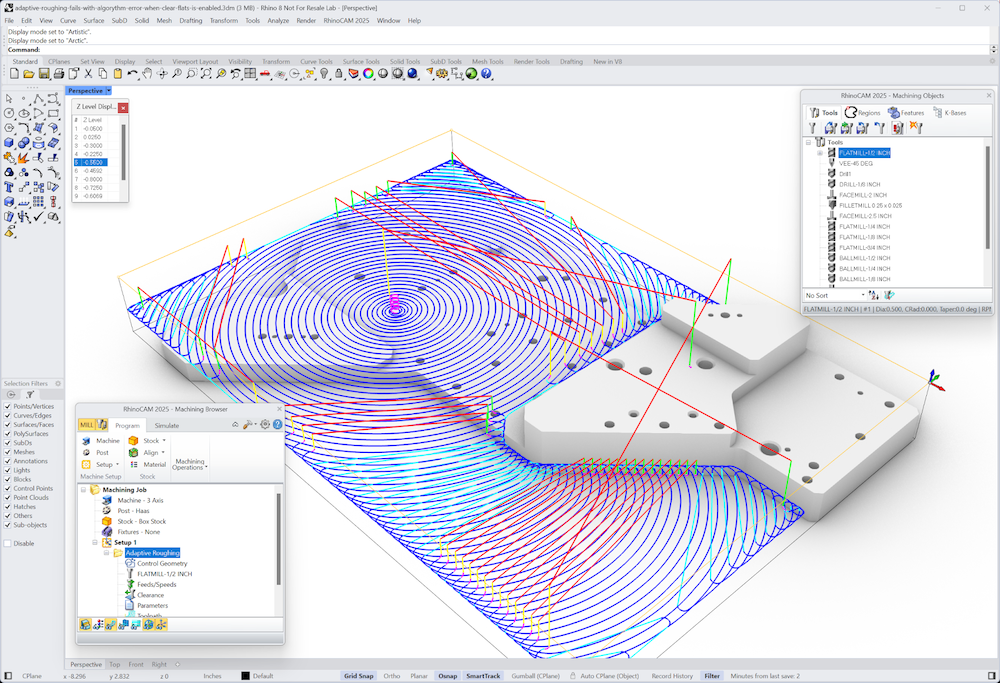

MecSoft Unveils RhinoCAM 2025 and VisualCAD/CAM 2025 with Enhanced Features

March 08, 2025 5 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …