Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

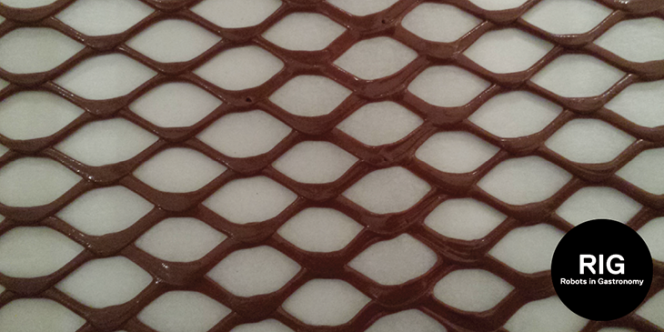

The Edge: FoodForm and Robots in Gastronomy

September 02, 2014 5 min read

Novedge: Tell us a bit about who you are and what you do

Luis E. Fraguada: My name is Luis E. Fraguada. My background is in Architecture and Environmental Design, but my central focus is on the application of computation on any given field of work or task. I teach computational tools at the Institute for Advanced Architecture of Catalonia in Barcelona, Spain, and I am the Research Director of Built by Associative Data which is an architecture and design studio specialized in offering analysis and performance based design solutions.

Robots in Gastronomy is a spin off from our research in the studio. We were working on custom digital fabrication machines and at the same time were meeting some chefs. One thing led to another and before we knew it, we were 3d printing food.

I also collaborate with my wife, Elizabeth Fraguada, on her fashion brand, Jorge & Esther. She and I designed the Lüme Collection, a series of garments with embedded technology that can be controlled wirelessly by your smartphone.

Novedge: What is or has been the biggest influence on your work?

Luis E. Fraguada: If I had to describe it in such detail, I would say it is a combination of the people I work with as well as the means by which we collaborate which almost always involves some sort of programming or computational process.

Novedge: In your research you bring together multiple disciplines. Can you talk about your approach to it?

Luis E. Fraguada: For me, I try not to see it as separate disciplines, but that is not to say that I am a master of many disciplines either. I find a common ground in what others might define as separate fields of knowledge. Again, I have to cite programming and computation as the means by which I feel I can do this. It is a way to structure solutions, a common means by which a designer can create protocols that are useful across disciplines.

Novedge: What is a recent project that you worked on?

Luis E. Fraguada:

FoodForm

The project that has been keeping me busy over the last few months is the development of the FoodForm 3D Food Printer. It is currently on its 3rd revision, and soon we will debut publically the 4th revision. One of my roles as Research Director at Built by Associative Data is to look outside of Architecture for knowledge and capabilities that might make our small studio operate differently. We were investigating the creation of custom 3d printing machines for several reasons: A.) to invent new techniques in how architecture could be fabricated, and B.) to learn about electronics, controlling motors, sensors, etc. At the same time we were collaborating with a chef on a separate project. The chef asked us why we could not just print the food directly? We thought this was an interesting challenge, and we tried several ways to deposit edible materials.

All of this research was consolidated last year in the FoodForm 3D Food Printer. We took all of the feedback from the chefs we worked with and developed a machine specifically for their kitchens. This is a tough environment for a moving mechanical platform depositing food, but through several design revisions, we've arrived at something we think could be interesting to chefs who want to invent new ways of cooking.

Most recently, we partnered with Cocktail Lab here in Barcelona. They have some incredible machines. For a long time we've been wanting to 3d print ice cream with the FoodForm, and Cocktail Lab had just the instrument which could make that happen. We combined the FoodForm with Polyscience's Anti-Griddle. The Anti-Griddle is just as it sounds, instead of heating a surface, it actually cools it to -34ºC/-30ºF. Any substance it touches freezes on impact. Last week we set out to formulate an ice cream recipe that would work well with the FoodForm, and achieved a very tasty homemade vanilla ice cream. We designed a few test pieces, and set out to 3d print them. The ice cream printing is part of a future project we are working on, but I am happy to say that our first experience with this ingredient was very successful!

Novedge: What software do you use?

Luis E. Fraguada: My platform of choice is McNeel's Rhinoceros 3d. I've been a user since 2005 and was really drawn to the flexibility of the software when it comes to extending its functionality. I can prototype the application of an algorithm in Grasshopper 3d, and then move that to C# and compile plugins. It is a platform that really lends itself well to working on diverse projects, be it food printing, fashion, architectural design. David Rutten's Grasshopper 3d has to be one of the most entertaining ways to develop an idea. Also, the people at McNeel (both in the United States and Europe) have been incredibly supportive, either via direct contact, or through the documentation. You get a feeling that the user can really influence the development of the software, which is something very unique.

Novedge: What are the challenges specific to 3d printing food?

Luis E. Fraguada: Beyond the manufacturing of the machine, there are two distinct challenges:

A. We do not focus on one material (as FDM printers do with ABS or PLA) so each ingredient has to be studied. Also, the flow of the ingredient is heavily dependent on ambient temperature and humidity. What can flow well one day, might not work well the next.

B. The most difficult challenge is that chefs do not necessarily learn CAD during their education. Actually, chefs are already thinking in 4D, they have to consider the time from the beginning of cooking a dish, to when it is consumed. So they are conceiving dishes in 4D, they are assembled in 3D. This is very difficult to digitize, which is what is needed in order to interface with the FoodForm 3D food printer which we make. We are in the process of developing interfaces for chefs which start to address this issue. Like most things challenging, this is also the most rewarding part to work on because you learn intimately how the mind of a chef works, which is a really fascinating thing.

Novedge: What rewards and challenges have you encountered in your professional life?

Luis E. Fraguada: The biggest challenge has been to find a platform where I am not focused specifically on one thing or one type of thing. I feel I work better when I am tasked to find solutions for diverse problems. This 'place' has not been easy to find, and in the end, it is why we formed Built by Associative Data, and why I am the Research Director. I had to build the platform where such a mode of working was viable.

Novedge: What's next for you?

Luis E. Fraguada: We are putting the finishing touches on the next revision of the FoodForm 3D Food Printer. This will debut at the London 3D Print Show September 4-6, 2014. We are excited to show the world the product of our labor. Built by Associative Data will begin construction of our first built project in Beirut, Lebanon towards the end of 2014. With Jorge & Esther we are working on something very interesting which will also be made public in the next months.

To see more of Luis's work, visit Built by Associative Data, Robots in Gastronomy and Jorge and Esther. Or connect with Luis on Twitter.

To be the first to read new interviews and blog posts, subscribe to the Novedge Blog here.

Related articles

Also in NOVEDGE Blog

How the AEC Industry Shifted Towards Essential Sustainable Building Design

August 15, 2024 4 min read

Read More

Unlocking New Realms of Design with Enscape 4.1: Introducing Impact Add-on and Lot More

August 02, 2024 2 min read

Read More

Explore Autodesk Revit 2025.2: New Features and Enhancements for Enhanced BIM Workflows

July 30, 2024 3 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …