Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Meet Miranda Bastijns of Materialise: “Our customers inspire us to do great things”

February 19, 2013 4 min read

3D printing is finally entering the consumers market, so I asked Miranda Bastijns, the Business Director of Units at i.materialise and .MGX to talk about her company and 3D printing.

Novedge: Tell us about yourself and your company.

Miranda Bastijns: Materialise is one of the pioneers of 3D printing. For over 20 years, our company has been making 3D prints and developing 3D print related software for the industrial and medical markets. All over the world hospitals and research institutes use our 3D printed models as customized drill and cutting guides, and anatomical models for surgery preparation and/or educational purposes. They also use our software in order to conduct research with virtual 3D models as well as in the creation of 3D models using their own printers. Also, a range of industrial sectors from aviation over automotive to consumer electronics are using the 3D prints of Materialise. It will be hard to find a type of car that Materialise has not supplied a prototyped part for. In 2003 Materialise expanded its range of services towards the consumer. For the first time in history, 3D printed design products became available on the market. This was the .MGX design collection, a range of high-end lamps and decorative elements straight from the 3D printer.

Designer: Patrick Jouin

At the end of 2009 we recognized a growing interest from the consumers to make their own designs. This was the start for i.materialise, the on-line 3D printing service for consumers. This implied that the over 80 printers of Materialise became available to everybody who wanted to make something. I think the name i.materialise is quite self explicative: “Materialise” should be seen as a verb, while the i is in fact I, me, myself, I materialise.

I have been with Materialise for 15 years. When I started, the company employed 40 people, now we are close to 1000. For years I have been responsible for the marketing. Not so easy to be in a commercial role in a company with mainly engineers. For a while I combined my role as marketing manager with the set-up of i.materialise, but very soon it was clear that i.materialise was growing too fast to combine it with another job. So now I am managing this fantastically interesting business unit full time.

Julia Vase 002 – Yin Yang by Virtox

Novedge: What inspires you?

Miranda Bastijns:If you really want to know who is inspiring in the 3D printing world, I am surrounded by so many inspiring figures at work that it is hard to think of any inspirations externally. Materialise has always been at the forefront of the 3D printing wave, trying out new things and going places where no other company had gone before. Many of my colleagues inspire me, for example, our CEO Fried – and many in the industry agree with me about what an inspiration he is. He was voted the most influential person in the industry in fact. Of course, looking beyond 3D printing there are numerous management books where we find inspiration. But also, just looking around and seeing what our customers do inspire us to do great things together with them, whether it is an inspiring design they come up with, or improving a clever software tool together with them…even going as far as developing life saving implants.

Bass Bracelet Constructionist by Maaike van der Horn

Novedge: What is a recent project that you worked on with i.materialise?

Miranda Bastijns:A very nice project is the recent launch of Twikit. Twikit is a start-up company that specializes in creating unique, customizable trophies. They developed an easy-to-use software tool by which people can make their own trophy, meaning every trophy is unique, which of course makes 3D printing the preferred method of production. Together with the people of Twikit, our engineering and customer support team looked into the best possible way to prepare the designs for 3D printing. And now that the product has been launched we are almost as proud of it as the Twikit boys. On top of the production, i.materialise also takes care of the logistic handling, including assembly, white labeling and shipment to customers. We have several of these kinds of start-ups that we collaborate with. And, each time one goes live, it’s quite exiting. Almost as exciting as starting your own business.

But of course, we are also touched by nice, one-off prints. It’s difficult to pick one as a favourite. Every day brings new beauties. I really like my job as I am on the forefront of many new and beautiful objects and projects that enter the world.

Lotus.MGX by Janne Kyttanen

Novedge: What software do you use at i.materialise?

Miranda Bastijns:Every 3D print starts by designing something in a software package or software tool. No file, no print. People uploading files at i.materialise use numerous design software packages, but many files are not immediately suitable for 3D printing. There are a multitude of software packages that can be used to design or model something for 3D printing, ranging from very high end CAD packages to relatively simple ones. Depending on your skills and what you want to make, you use the one or the other. For beginners there are Autodesk123D, Tinkercad, 3DTin and SketchUp.We use Magics, a software package developed in-house at Materialise in order to check and fix files. Then our own Streamics software takes care of the back end and of course we have Materialise’s hundreds of software developers doing whatever is needed to ensure that our web service run smoothly.

36 Pencil Bowl by Michiel Cornelissen

Novedge: What innovations do you see in your field?

Miranda Bastijns:More materials, more materials, and more materials. Thousands of new design tools to make your own something special. More user friendly and better home printers. And, for sure, many more medical applications of 3D printing.

To learn more about Materialise, visit their website.

Also in NOVEDGE Blog

Enhance Your Designs with VisualARQ 3: Effortless Geometry Extensions for Walls and Columns

April 30, 2025 8 min read

Read More

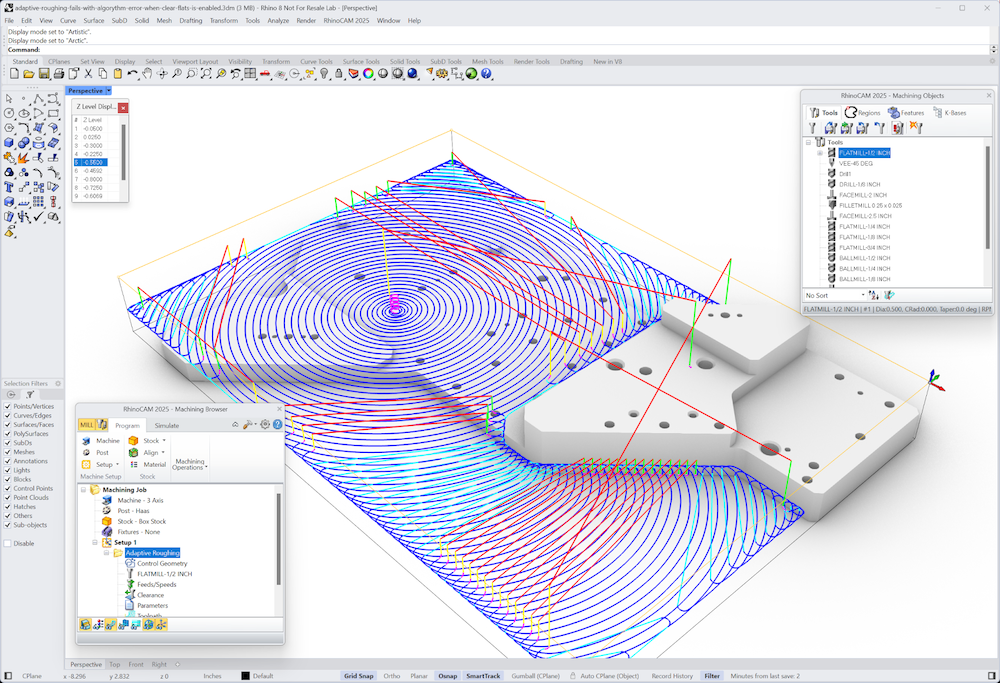

MecSoft Unveils RhinoCAM 2025 and VisualCAD/CAM 2025 with Enhanced Features

March 08, 2025 5 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …