Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Unleashing Innovation with Design for Additive Manufacturing: Overcoming Constraints and Embracing Future Trends

July 26, 2024 3 min read

Introduction to Design for Additive Manufacturing (DfAM)

The landscape of manufacturing has undergone a significant transformation with the advent of additive manufacturing (AM) technology. Once primarily used for prototyping, AM has evolved to offer unparalleled design freedom and the ability to fabricate complex geometries that were previously unachievable or prohibitively expensive with traditional manufacturing methods. This shift from traditional constraints to design freedom marks the essence of Design for Additive Manufacturing (DfAM). DfAM leverages the capabilities of AM to create designs that optimize material usage, enable customization, and achieve complex geometries with enhanced functionality and performance.

The key benefits of DfAM include the ability to produce complex and intricate designs, the potential for high levels of customization, and improved material efficiency through the reduction of waste. These advantages open up new possibilities in various industries, from aerospace and automotive to medical devices and consumer products.

Overcoming Traditional Design Constraints

The transition to additive manufacturing enables designers and engineers to overcome many of the limitations inherent in traditional manufacturing. Where traditional methods impose constraints on part complexity, material usage, and the economics of customization, additive manufacturing offers a new paradigm.

- Material usage and waste reduction: AM builds parts layer-by-layer, significantly reducing material waste compared to subtractive manufacturing processes.

- Complexity and cost relationship: Unlike traditional manufacturing, where increased complexity often leads to higher costs, AM maintains cost-effectiveness across varying levels of complexity.

- Customization at scale: AM allows for high levels of customization without the need for tooling changes, making it economically feasible to produce small batches of customized products.

Through specific examples, it is evident that redesigning parts for additive manufacturing can achieve optimizations not possible with conventional methods, underscoring the transformative potential of DfAM in overcoming traditional design constraints.

Principles and Best Practices in DfAM

To fully leverage the capabilities of additive manufacturing, a shift in the design mindset is essential. Designers and engineers must rethink design processes and principles, focusing on the unique advantages and considerations of the AM process.

Key DfAM considerations include the orientation of the part during printing, optimization of support structures to minimize material use and post-processing, the incorporation of lattice structures for material efficiency and functional performance, and the application of topology optimization to achieve optimal material distribution and performance characteristics.

Software tools play a crucial role in facilitating effective DfAM strategies by providing simulations and analyses that inform design decisions. Additionally, understanding material properties and selecting the appropriate materials are critical to achieving desired outcomes in additive manufacturing.

Future Trends and Challenges in DfAM

The field of additive manufacturing is rapidly evolving, with advancements in materials, technologies, and processes continuously expanding the boundaries of what is possible. Looking forward, the integration of AI-driven design, multi-material printing, and the incorporation of electronics into 3D printed parts are among the most promising developments in DfAM.

However, integrating DfAM into existing manufacturing ecosystems presents several challenges, including the need for new design skills, the adaptation of supply chains, and the development of standards and certifications. Despite these challenges, the potential for innovation and efficiency gains makes the pursuit of advanced DfAM capabilities a compelling proposition for industries across the spectrum.

Education and skill development for designers and engineers is paramount to unlocking the full potential of DfAM. As the technology continues to mature, the cultivation of a skilled workforce equipped with the knowledge and tools to innovate in the realm of additive manufacturing will be critical to achieving the transformative impacts envisioned by the pioneers of DfAM.

Also in Design News

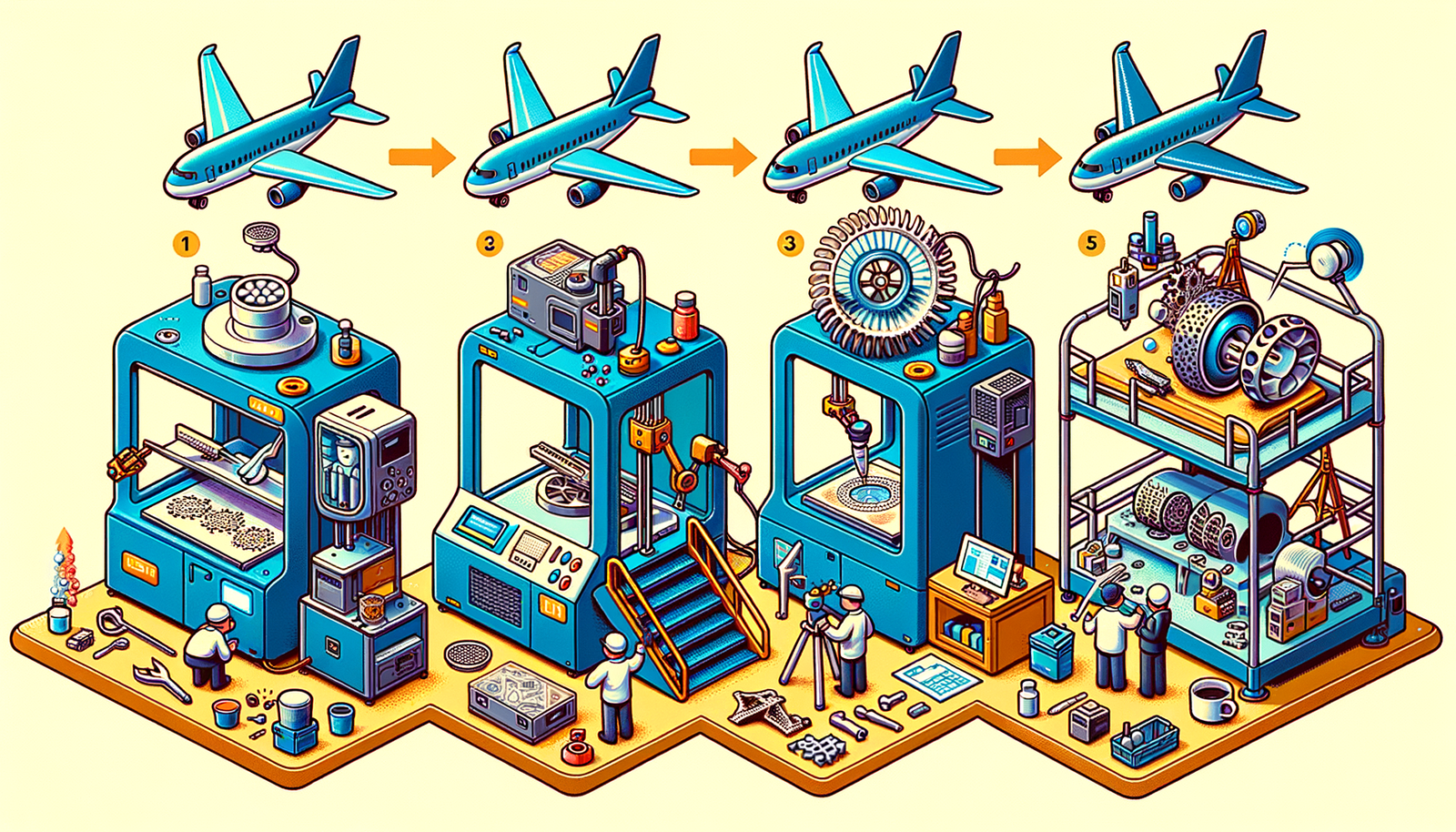

Design Software History: The Evolution of 3D Printing in Aerospace: From Prototyping to Production

November 27, 2024 7 min read

Read More

Cinema 4D Tip: Optimizing Workflow with Team Render in Cinema 4D

November 27, 2024 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …