Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Revolutionizing Design and Manufacturing: The Impact of Digital Twins

July 20, 2024 2 min read

Introduction to Digital Twins

Digital twins have emerged as a groundbreaking technology in the realm of design and product lifecycle management. At its core, a digital twin is a dynamic, digital replication of a physical object or system. This technology facilitates a deep connection between the physical and virtual worlds, allowing for real-time monitoring and simulation. The concept, though rooted in decades of technological evolution, has gained significant momentum with advancements in IoT, AI, and data analytics, becoming increasingly crucial across various industries.

How Digital Twins Transform Design Processes

The integration of digital twins into the design phase marks a transformative step towards more efficient and effective design methodologies. By leveraging real-time simulation, analysis, and optimization capabilities, engineers and designers can anticipate how products will perform under various conditions, thereby significantly reducing design time, enhancing product functionality, and spurring innovation. This section further delves into the practical implications of digital twins on the design process.

- Real-time simulation offers the ability to test designs under different scenarios without the need for physical prototypes.

- Analysis of data gathered from digital twins helps in understanding the nuances of product performance and areas for improvement.

- Optimization processes are streamlined, enabling the fine-tuning of designs with greater accuracy and efficiency.

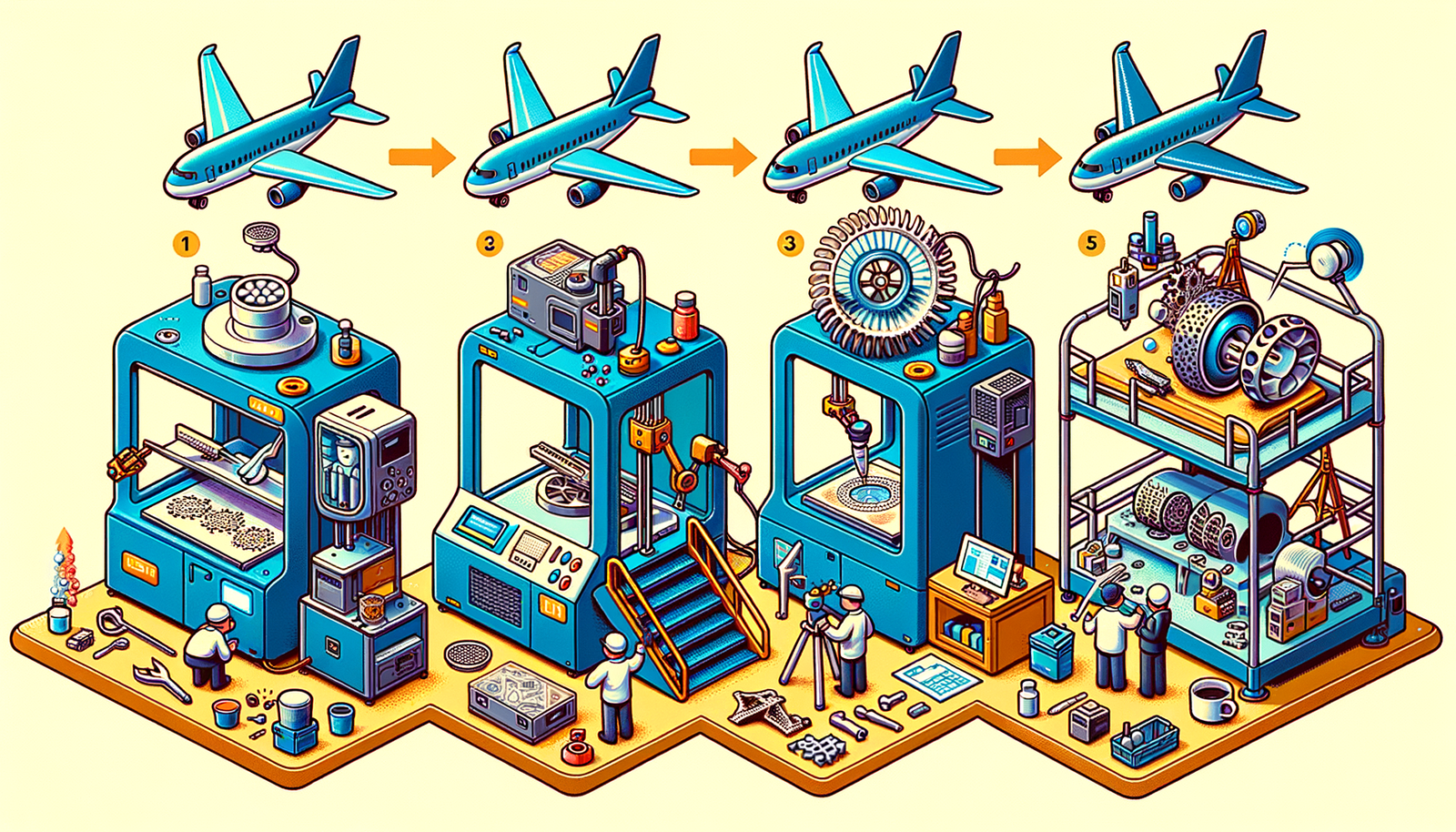

The Role of Digital Twins in Additive Manufacturing and Beyond

The intersection of digital twins and additive manufacturing represents a significant leap towards more advanced manufacturing techniques. This synergy not only enhances precision and efficiency but also enables customization at scale, transforming the production landscape. Furthermore, the application of digital twins extends into maintenance, repair, and operations (MRO), offering unprecedented insights and operational efficiencies.

- Enhancing precision and efficiency in the manufacturing process by predicting outcomes and identifying potential issues before they arise.

- Enabling customization at scale by allowing for the modification of digital twins to suit individual customer requirements without significant increases in cost or time.

- Reducing material waste and production costs through optimized design and manufacturing processes.

Future Trends and Challenges

The future of digital twins holds immense promise for design software and processes. Advancements in technologies such as AI, machine learning, and cloud computing are set to further augment the capabilities of digital twins, opening up new avenues for innovation. However, the path forward is not without its challenges. Technical complexities, integration with existing systems, and concerns regarding data security and privacy are notable hurdles that must be addressed to unlock the full potential of digital twins.

- Technical complexities associated with creating and maintaining accurate digital twins can pose significant challenges, especially for complex systems.

- Integration with existing systems remains a complicated endeavor, requiring significant investment in terms of time and resources.

- Data security and privacy concerns are paramount, given the sensitive nature of the data involved in creating and operating digital twins.

In conclusion, the journey towards fully embracing digital twin technology is fraught with challenges but offers substantial rewards. For designers, engineers, and manufacturers, the adoption of digital twins presents a compelling opportunity to gain a competitive edge and drive sustainability in an increasingly digital world. As we look to the future, it is clear that digital twins will continue to play a pivotal role in reshaping the landscape of product lifecycle management.

Also in Design News

Design Software History: The Evolution of 3D Printing in Aerospace: From Prototyping to Production

November 27, 2024 7 min read

Read More

Cinema 4D Tip: Optimizing Workflow with Team Render in Cinema 4D

November 27, 2024 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …