Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Integrating Collaborative Robots in Manufacturing: The Role of Advanced Design Software

June 10, 2024 2 min read

Introduction to Collaborative Robotics and Design Software

The manufacturing landscape is undergoing a transformative shift with the advent of Industry 4.0, characterized by the integration of smart technologies into manufacturing processes. At the heart of this technological revolution are collaborative robots (cobots), designed to work alongside human operatives, enhancing productivity and flexibility. The significance of cobots lies in their ability to democratize automation, making it accessible to a wider range of industries, including small and medium enterprises.

Central to the effective integration of cobots into manufacturing workflows is design software. These advanced software solutions are crucial for programming, controlling, and optimizing cobot operations, ensuring seamless human-robot collaboration.

Advancements in Design Software for Cobots

The realm of design software for cobots has seen significant advancements, making the programming and control of these robotic assistants more intuitive and efficient. Noteworthy features include:

- Graphical programming environments that allow users to visually map out cobot tasks.

- Simulation capabilities that enable designers to test and refine cobot workflows in a virtual environment.

- Integration tools that facilitate seamless communication between cobots and other manufacturing systems.

These advancements underscore the importance of user-friendly interfaces, allowing engineers and designers to harness the full potential of cobots without the need for deep programming expertise.

The Impact of Cobots on Manufacturing Efficiency and Creativity

Cobots, driven by sophisticated design software, have a profound impact on manufacturing efficiency. By taking over repetitive, labor-intensive tasks, cobots free human workers to focus on more complex and creative aspects of production. This collaboration leads to:

- Reduced production times and increased throughput.

- Improved product quality and consistency.

- Enhanced worker safety and ergonomics.

Beyond efficiency gains, cobots have sparked creativity in various industries. From customizing products on the fly to developing innovative solutions for traditional manufacturing challenges, the versatility of cobots is a catalyst for creative problem-solving. This is only set to expand as design software becomes even more capable, offering new ways for industries to utilize cobots.

Challenges and Future Outlook

The integration of cobots into manufacturing processes is not without challenges. Key among these is the compatibility of cobots with existing design software systems. Many industries find themselves grappling with the need to overhaul or significantly upgrade their software infrastructure to fully benefit from cobot technology. Additionally, there is an urgent need for education and training among engineers and designers to keep pace with the evolving landscape of collaborative robotics.

Looking ahead, the future of design software in relation to cobots is incredibly promising. Innovations are likely to focus on enhancing interoperability, simplifying user interfaces, and expanding the capabilities of cobots through advanced computing techniques like machine learning and artificial intelligence. This evolution will not only address current challenges but also unlock new avenues for the application of cobots, potentially transforming manufacturing industries in ways we are just beginning to imagine.

Also in Design News

Design Software History: Visualizing Engineering Intent: Feature Histories, Constraints, and Semantic PMI in CAD

December 29, 2025 16 min read

Read More

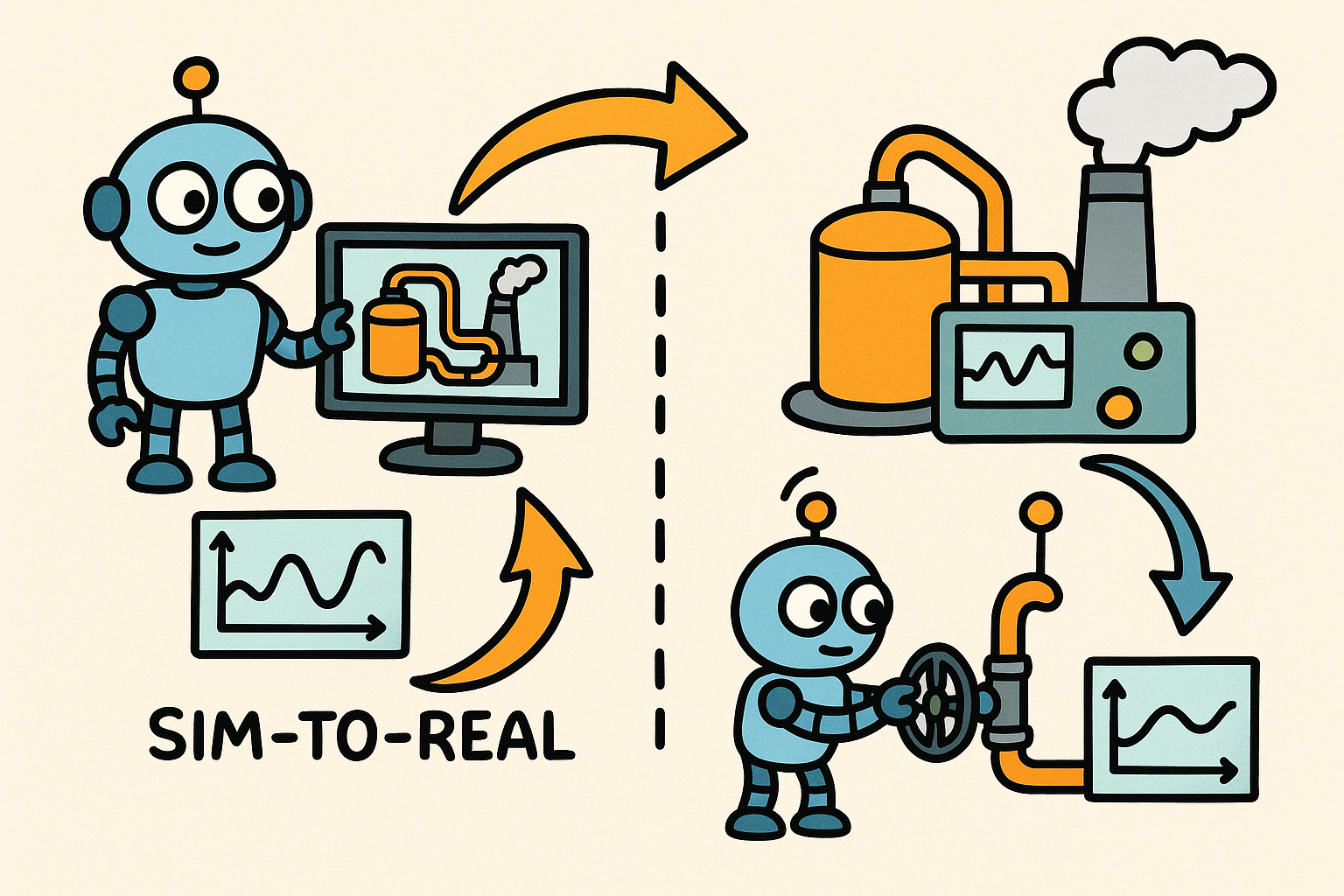

Sim-to-Real Transfer for Closed-Loop Process Calibration and Control

December 29, 2025 12 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …