Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Harnessing Machine Learning for Advanced Predictive Maintenance in Product Design

May 19, 2024 2 min read

Introduction to Predictive Maintenance through Machine Learning

In the dynamic realm of product design, the advent of predictive maintenance has marked a significant evolution, shifting the focus from reactive to proactive measures. This transformative approach, powered by machine learning (ML), leverages data analytics to predict equipment failures before they occur, ensuring uninterrupted operation and longevity of products.

Machine learning, a subset of artificial intelligence, plays a pivotal role in this paradigm shift. By analyzing vast amounts of data, ML algorithms can identify patterns and predict possible breakdowns, making predictive maintenance not just a possibility but a reality in today's advanced design processes.

The transition from traditional to predictive maintenance strategies, enabled by sophisticated design software, signifies a leap towards more efficient, reliable, and cost-effective product design and maintenance.

Machine Learning Algorithms for Predictive Maintenance

Predictive maintenance utilizes a variety of machine learning algorithms to forecast equipment failure, including:

- Regression algorithms for predicting continuous outputs,

- Neural networks for their ability to learn complex patterns from data, and

- Decision trees for their simplicity and interpretability.

Integrating these algorithms into design software enables the prediction of potential failures, transforming how products are designed, maintained, and serviced. Through advanced analytics, designers and engineers can anticipate issues and mitigate them before they escalate into costly downtime.

While specific case studies are not discussed here, numerous industries including aerospace, manufacturing, and automotive have successfully implemented predictive maintenance strategies, showcasing significant improvements in product reliability and operational efficiency.

Benefits and Challenges

The adoption of machine learning for predictive maintenance brings forth a plethora of benefits, chiefly:

- Reduced downtime, as potential issues are addressed before they lead to equipment failure,

- Cost savings through optimized maintenance schedules and reduced need for emergency repairs, and

- Improved product reliability, enhancing customer satisfaction and trust.

However, the path to implementing predictive maintenance is not devoid of challenges. Key considerations include the quality of data available for analysis, the selection of the most appropriate machine learning algorithm for specific maintenance tasks, and the seamless integration of these technologies into existing design and maintenance workflows.

Designers can navigate these challenges by prioritizing high-quality data collection, selecting algorithms based on the specific needs of their maintenance tasks, and adopting design software that facilitates easy integration of predictive maintenance capabilities.

Future Trends and Developments

The future of machine learning in predictive maintenance is poised for remarkable advancements. As algorithms become more sophisticated and data processing capabilities enhance, the integration of predictive maintenance into design processes will become even more seamless and efficient. Furthermore, the convergence of machine learning with the Internet of Things (IoT) devices promises to revolutionize how designers monitor and maintain equipment.

The role of design software is evolving to not only facilitate these advanced predictive maintenance practices but also to empower designers to stay ahead of technological developments. By leveraging cutting-edge design software, professionals can ensure their products are not only innovative but also reliable and maintainable in the long term.

In conclusion, the importance of embracing these technological advancements cannot be overstated. As machine learning and predictive maintenance continue to advance, staying informed and adaptable will be key for designers aiming to achieve excellence in product design and maintenance.

Also in Design News

Design Software History: From Usenet to Cloud: How Forums, Tutorials, and Open Libraries Transformed CAD Practice

February 07, 2026 13 min read

Read More

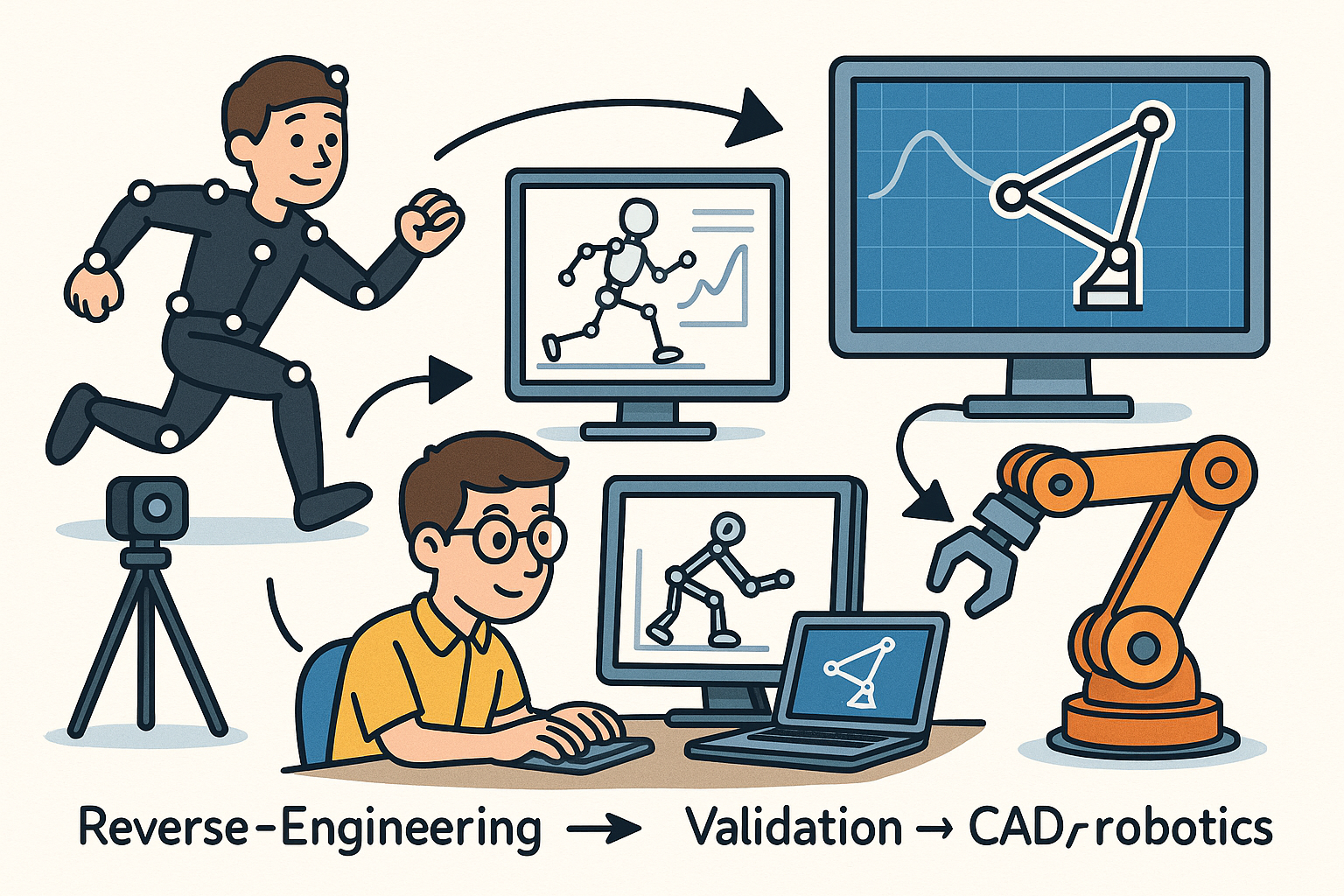

Reverse-Engineering Mechanisms from Motion Capture: Kinematic Identification, Validation, and CAD/Robotics Export

February 07, 2026 12 min read

Read More

Cinema 4D Tip: Guide-First Hair Grooming Workflow for Cinema 4D

February 07, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …