Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Evolution and Future of 3D Printing Software: Historical Milestones, Current Innovations, and Emerging Trends

September 01, 2024 4 min read

Historical Overview of 3D Printing Software

Early Beginnings

The early days of 3D printing software were marked by simplicity and limited functionalities. The first generation of 3D printing software primarily focused on basic slicing tasks. This software took 3D models and converted them into instructions that 3D printers could understand. The functionalities were minimal, often limited to layering and rudimentary path generation.

Key milestones during this period included the introduction of pioneering software like MakerWare and Skeinforge. These early tools were instrumental in transitioning from theoretical concepts to practical applications of 3D printing. They set the groundwork for the sophisticated tools we have today.

Evolutionary Phases

As the demand for 3D printing grew, so did the complexity and capabilities of the software. The transition from basic slicing software to more advanced design tools began. New features were introduced, such as support generation, which allowed for more intricate designs, and infill patterns, which optimized the strength and weight of printed objects.

The introduction of multi-material capabilities represented a significant leap forward. Users could now print with different materials in a single print job, opening up a myriad of possibilities for complex and functional designs.

Impact of Open-Source Movements

The open-source movement had a profound impact on the evolution of 3D printing software. Projects like Cura and OctoPrint democratized access to advanced 3D printing capabilities. These open-source platforms encouraged community contributions and collaborations, driving rapid innovation.

The collective efforts of hobbyists, developers, and researchers led to the development of robust features and improvements that would not have been possible within the constraints of proprietary software. This has significantly broadened the user base and accelerated technological advancements.

Current State of 3D Printing Software

Diverse Software Ecosystem

The current landscape of 3D printing software is characterized by a diverse ecosystem catering to different aspects of the 3D printing process. The software can be broadly categorized into:

- Slicing Software: These are used to convert 3D models into printable layers. Examples include Cura, Simplify3D, and PrusaSlicer.

- Design Software: These tools are used to create and modify 3D models. Popular options include AutoCAD, SolidWorks, and Blender.

- Print Management Software: These tools help manage multiple printers and print jobs. Examples include OctoPrint and Repetier-Server.

Each category has leading software products that offer unique features tailored to specific user needs, from hobbyists to industrial applications.

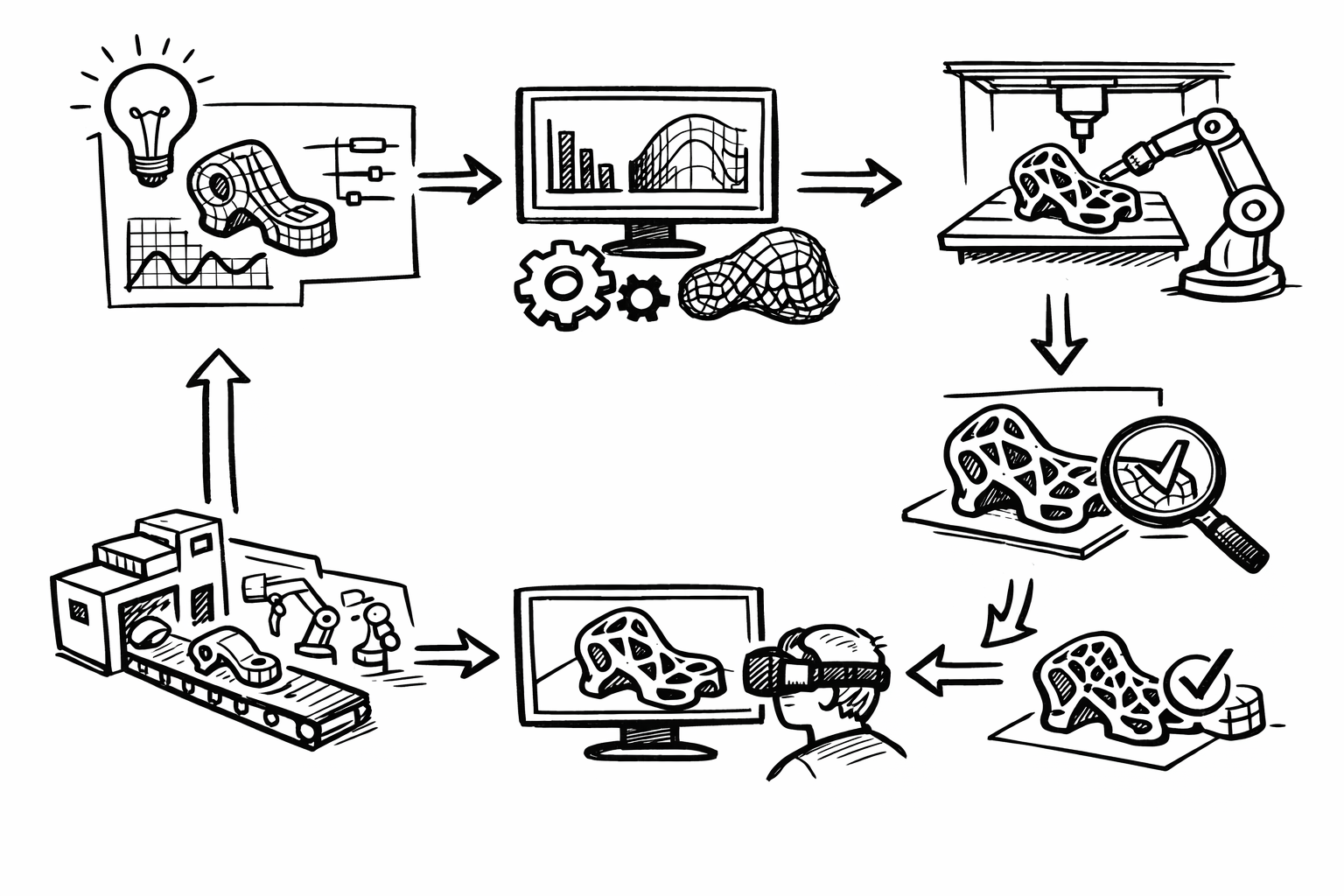

Integration with Other Technologies

Modern 3D printing software does not operate in isolation. It integrates seamlessly with other technologies such as CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), and ERP (Enterprise Resource Planning) systems. This integration streamlines workflows, from initial design to final production, enhancing efficiency and reducing errors.

Cloud services have also become integral, offering remote monitoring and management capabilities. Users can now oversee multiple printers from anywhere in the world, ensuring that print jobs are completed correctly and on time.

User-Friendly Features

The focus on user experience has led to the development of more user-friendly interfaces and features. Modern 3D printing software often includes automated settings and profiles for different materials and printer models, simplifying the printing process for users of all skill levels.

These enhancements make it easier for beginners to get started with 3D printing while providing advanced options for more experienced users, thereby bridging the gap between novice and expert users.

Emerging Trends and Innovations

Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing 3D printing software. AI is being implemented for predictive maintenance and print quality optimization. It can predict when a printer might fail or need maintenance, reducing downtime and increasing productivity.

Machine learning algorithms are being used for automated design adjustments and error corrections. These intelligent systems can learn from previous prints to improve future performance, leading to higher quality prints and fewer failed jobs.

Generative Design

Generative design is another cutting-edge innovation transforming the field. This technology uses algorithms to create optimized and innovative structures based on user-defined parameters. It allows for the creation of designs that would be impossible or highly impractical to achieve manually.

Generative design is particularly beneficial in industries like aerospace and automotive, where weight reduction and strength optimization are critical. It not only enhances performance but also drives innovation by exploring a wider range of design possibilities.

Advanced Material Handling

Software advancements in handling multi-material and composite printing are enabling more complex and functional prints. These advancements allow for the combination of different materials within a single print, such as combining rigid and flexible materials or incorporating conductive materials for electronic applications.

The integration of material science with 3D printing software is also playing a crucial role. It helps in understanding the properties and behaviors of different materials, leading to better performance and sustainability in printed products.

Future Directions and Challenges

Customization and Personalization

The future of 3D printing software holds immense potential for highly customized and personalized solutions. This is particularly relevant in sectors like healthcare, where personalized medical devices and prosthetics can significantly improve patient outcomes.

Software will play a pivotal role in enabling mass customization, allowing manufacturers to produce unique, tailored products at scale. This shift will redefine traditional manufacturing paradigms and open up new business opportunities.

Scalability and Industrial Adoption

One of the significant challenges facing 3D printing is scaling from prototyping to full-scale manufacturing. Issues like consistency and reliability need to be addressed to make 3D printing viable for industrial production.

Solutions are being developed to tackle these challenges, including more robust software algorithms and better integration with industrial workflows. These advancements aim to improve the repeatability and reliability of 3D printed parts, making large-scale adoption more feasible.

Sustainability and Environmental Impact

As concerns about environmental impact grow, efforts to make 3D printing more sustainable are gaining traction. Software innovations are crucial in this regard, enabling simulation and optimization to reduce waste and energy consumption.

By optimizing print paths, reducing material usage, and improving energy efficiency, software can significantly mitigate the environmental impact of 3D printing. These efforts are essential for making 3D printing a more sustainable and responsible manufacturing option.

Also in Design News

Subscribe

Sign up to get the latest on sales, new releases and more …