Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

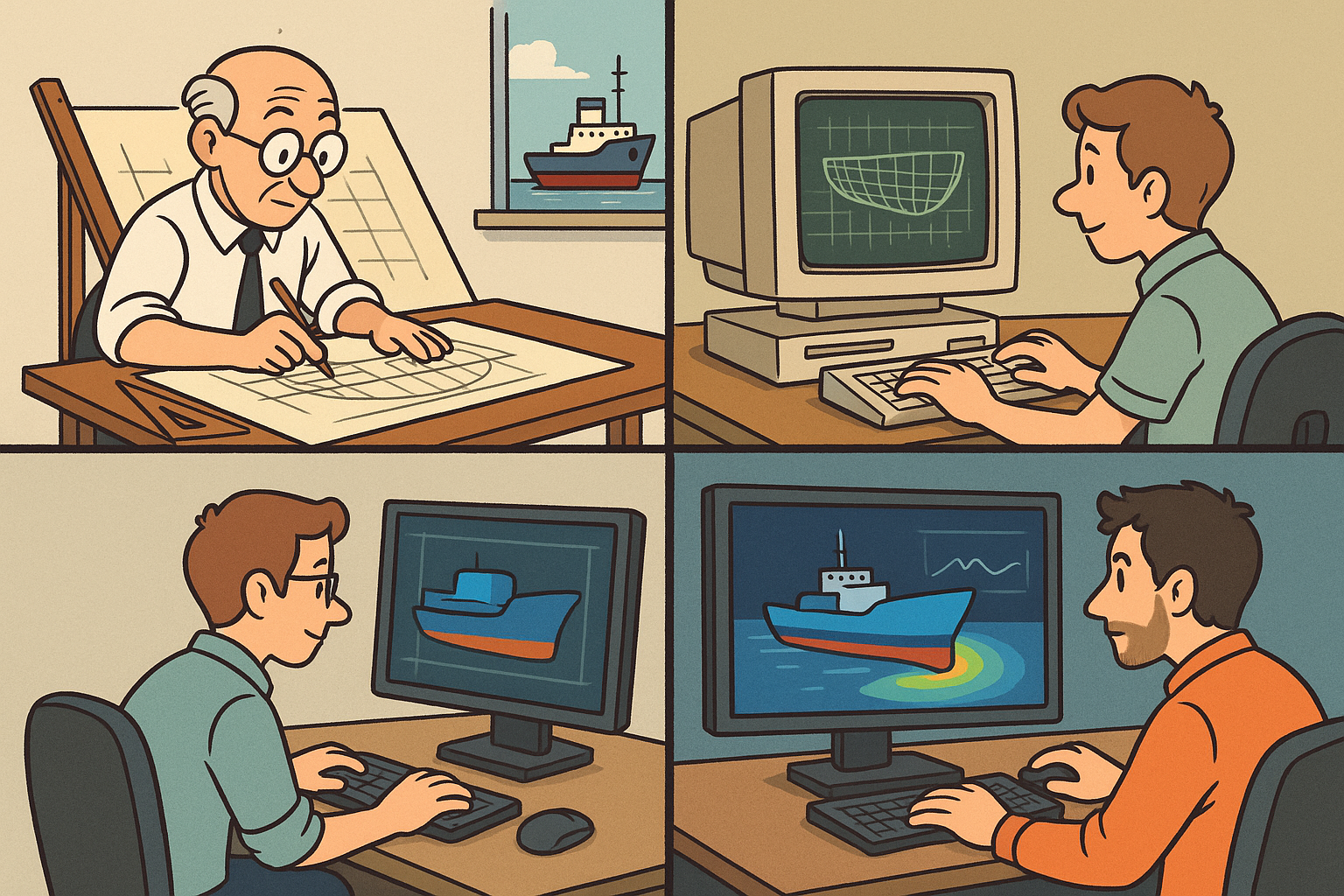

Design Software History: The Evolution of Marine Design Software: From Manual Drafting to Advanced Integrated Simulation Technologies

July 15, 2025 10 min read

Introduction and Historical Context

Marine design software occupies a unique niche within the shipbuilding industry by combining the rigorous demands of marine engineering with the creative challenges of advanced digital design. In defining marine design software, we refer to specialized computer applications that support the design, analysis, and simulation of maritime vessels. These systems have evolved over decades to meet the diverse and often competing requirements of ship construction—from hydrodynamic performance prediction to ensuring safety standards meet stringent regulatory requirements. Historically, traditional ship design was burdened by manual drafting, painstaking computation, and lengthy revision cycles that often limited engineers to iterative hand-drawn sketches and physical models. The digital transformation that began to take shape in the late 20th century has dramatically altered the landscape of ship design, prompting a shift in mindset from purely analog techniques to integrated, computer-aided processes that enhance precision and design flexibility.

Early Challenges in Traditional Ship Design and Engineering

The challenges in early ship design were not merely technical; they also encompassed logistical and managerial dimensions. Shipbuilders traditionally relied on manual drafting practices that required skilled draftsmen, and even minor errors in calculations would result in potentially hazardous design errors. Due to these intrinsic limitations, the industry faced long development cycles and reduced responsiveness to evolving regulatory environments. Moreover, these processes exerted a heavy toll on resource expenditures and time management, thereby amplifying the pressing need for integrated digital solutions that could streamline operations while simultaneously contributing to more reliable designs. The emphasis for many decades was directed towards safety and reliability, with only incremental improvements accompanying design enhancements. The shift from these early techniques to reliable computational methods marked the beginning of a substantial industry transformation that reimagined the use of technology in maritime design.

Timeline of Digital Transformation in the Maritime Industry

The digital transformation in marine design has a well-documented historical timeline. During the 1960s and 1970s, certain early computer-aided design (CAD) systems began emerging, initially meeting the needs of more generalized engineering tasks. Although these early systems were rudimentary by modern standards, they laid the groundwork for a more comprehensive integration of digital methods into shipbuilding. As computing power advanced in the 1980s and 1990s, dedicated applications for maritime design started to appear, supplementing traditional techniques and enabling designers to undertake complex analyses with increasingly greater levels of accuracy. The ensuing decades witnessed rapid evolution—from basic two-dimensional representations to sophisticated three-dimensional modeling, simulations, and structural integrity analyses. This transformation revolutionized how naval architects approached everything from hull design to propulsion system integration. The adoption of innovative software paradigms not only improved operational efficiency but also dramatically reduced design cycle times, significantly changing the landscape of maritime engineering.

Pioneering Innovations and Technological Milestones

The evolution of marine design software has been punctuated by a series of pioneering innovations that have redefined the parameters of shipbuilding design capabilities. The transition from manual drafting to computer-aided design marked a seismic shift in the industry, where technological advancements began to provide engineers with tools that increased both the speed and the accuracy of their designs. Early CAD systems tailored specifically for marine applications enabled designers to integrate complex architectural specifications with aerodynamic and hydrodynamic analyses. This critical evolution not only streamlined processes but also introduced new dimensions of accuracy in hull and structural simulations—components that were previously relegated to mere estimations. The industry's gradual move from traditional drafting towards digital automation quickly positioned marine design software as an essential component in reducing error margins, lowering production costs, and enhancing overall vessel performance.

Transition from Manual Drafting to Computer-Aided Design

The most fundamental innovation in marine design was the shift from manual drafting to computer-aided design (CAD) systems. This transition was fueled by the necessity to overcome the inherent limitations of hand-drawn plans, which were often subject to inconsistencies and required repeated iterations for any modifications. CAD software, while initially developed for architectural and general engineering disciplines, was swiftly adapted to cater to the unique requirements of ship design. Early CAD systems provided functionalities such as geometric construction, drafting tools, and editing capabilities that were completely revolutionary at the time. These tools allowed marine engineers to design intricate hull structures with an unprecedented level of precision, and the corresponding design data could be easily updated and shared among multiple departments, thereby reducing communication errors and streamlining workflow processes. The advent of computer-aided drafting instigated a paradigm shift in how maritime projects were conceptualized, designed, and executed.

Adoption of 2D and Early 3D Modeling Techniques

Complementing the advances in CAD technology was the emergence and refinement of 2D and 3D modeling techniques. Initially, the adoption of these methods offered engineers the ability to visualize ship components in greater detail compared to traditional blueprints. Over time, the implementation of early 3D modeling techniques allowed for the creation of more realistic representations of ship structures, facilitating more sophisticated simulations and performance evaluations. In contrast to 2D representations, these early 3D models equipped designers with a more intuitive understanding of spatial relationships, complex curvatures, and intersecting structural components. The shift to 3D modeling was pivotal for analyzing the aerodynamic and hydrodynamic properties of hull surfaces, enabling engineers to perform simulations that were closer to real-world conditions. The improvements in modeling techniques were essential for the evolution of marine design, especially as the demands for interoperability between design software and simulation tools increased, paving the way for more integrated and holistic design processes.

Introduction of Solid and Geometric Modeling in Shipbuilding

The emergence of solid and geometric modeling further revolutionized marine design. This new approach enabled the detailed representation of both the exterior hull and the internal structure of vessels. Early implementations of solid modeling algorithms allowed for the capture of complex geometric shapes and facilitated the use of simulations to test various structural hypotheses under dynamic conditions. Geometric modeling techniques permitted a granular breakdown of hull surfaces, which was essential for accurate hydrodynamic and structural analysis. These technological breakthroughs provided critical insight into how minor deviations in design could affect overall vessel performance, such as speed, stability, and safety. The transition to solid and geometric modeling was a turning point, as it not only established new safety standards but also allowed for more efficient iterative design practices. The ability to integrate hydrodynamic analysis with structural integrity assessments has become a hallmark of modern marine design, fundamentally altering the process by which naval architects approach the creation of safer and more efficient ships.

Advancements in Hull Surface Representation and Structural Simulations

One of the most important innovations in marine design software is the development of systems capable of detailed hull surface representation coupled with advanced structural simulations. The representation of the hull is not merely an aesthetic concern—it directly influences the vessel's hydrodynamic performance. Modern software leverages solid modeling techniques to capture the complexities of a ship’s curvature, incorporating minute details that have significant consequences for drag reduction and overall speed. These innovations also extend to the prediction of structural stresses and load distributions across the vessel's framework. Enhanced simulation tools allow for comprehensive assessments under various operational scenarios, including extreme weather conditions and collision impacts. By incorporating these features, designers can develop models that not only optimize performance but also ensure compliance with international maritime safety standards. Additionally, the integration of structural simulations into the design phase has paved the way for more predictive maintenance strategies, reducing the likelihood of catastrophic failures during the lifespan of maritime vessels.

Key Breakthroughs in Integrating Hydrodynamic Analysis

A critical milestone in the evolution of marine design software was the integration of sophisticated hydrodynamic analysis tools. Hydrodynamic analysis encompasses a comprehensive evaluation of how water flows around the vessel’s hull, impacting speed, stability, and fuel efficiency. Prior to the development of integrated simulation tools, engineers were often forced to rely on empirical data and simplified mathematical models, which could not fully account for the complex interactions between wave dynamics and ship geometry. The incorporation of computational fluid dynamics (CFD) algorithms into marine design software allowed for real-time analysis of water flow, predicting areas of turbulence and potential cavitation. This breakthrough not only refined the precision of design but also dramatically improved the optimization of hull forms, ensuring that vessels could operate at maximum efficiency under varying load conditions. The ability to simulate these interactions digitally has greatly enhanced safety measures, enabling proactive adjustments long before prototypes ever hit the water. The amalgamation of hydrodynamic analysis with solid and geometric modeling represents a pivotal advancement, empowering designers to deliver more resilient and high-performing maritime vessels.

Industry Impact and Influential Contributions

The transformative impact of marine design software on the shipbuilding industry cannot be overstated. In addition to stimulating increased efficiency and innovation in ship construction, this digital revolution has fundamentally redefined the roles of engineers and designers. Groundbreaking software platforms have enabled companies to transition workflows from traditional labor-intensive processes to highly automated, iterative cycles that facilitate rapid prototyping and real-time simulation. At the core of this transformation are software developers and pioneering companies whose contributions spanned from initial CAD implementations to recent advancements in simulation and integrated design ecosystems. The ripple effects of these innovations continue to shape the industry, driving enhancements in safety, cost efficiency, and overall project management. Over the years, influential players in the field have provided robust toolsets that significantly reduce errors and rework, ensuring that every design is grounded in both precision and practicality.

Notable Companies and Software Developers Shaping Marine Design

Numerous influential companies and software developers have left an indelible mark on the evolution of marine design software. Firms such as Siemens PLM Software, Dassault Systèmes, and Bentley Systems have been at the forefront of developing systems that integrate not only design functionalities but also simulation capabilities for dynamic analysis and environmental impact assessments. Each of these companies has played a pivotal role in demonstrating how specialized applications can transform the shipbuilding process—from initial design sketches to final construction details. Their respective platforms have effectively bridged the gap between theoretical models and real-world applications, providing designers with an essential toolkit to predict performance outcomes accurately and ensure compliance with maritime safety standards. While the industry has witnessed a multitude of contributions, it is the vision and dedication of the developers behind these platforms that have catalyzed momentum, setting the stage for continuous improvement and innovation that spans multiple decades.

Contributions of Pioneers and Thought Leaders in Marine Design

Furthermore, the evolution of marine design software has been driven by the relentless pursuit of excellence by numerous pioneering individuals across the fields of computer science, naval engineering, and simulation technology. Thought leaders in these domains not only pushed the boundaries of what was technologically feasible but also integrated cross-disciplinary approaches that brought novel insights into the mechanics of ship design. Their work has resulted in software enhancements that allow for the holistic integration of various design modules—from hydrodynamic and structural simulations to material performance analysis. Key insights from these experts have emphasized the importance of iterative design and cross-functional collaboration. This integrated approach ensures that every element of a vessel’s design is optimized, resulting in improved safety and operational efficiency over its lifespan. The tireless work of these pioneers continues to be a driving force behind emerging technologies that promise to further revolutionize the field, pushing the envelope of maritime design innovation and reinforcing the critical role of digital transformation within shipbuilding.

Impact on Efficiency, Safety, and Innovation in Ship Construction

The incorporation of advanced marine design software has resulted in significant improvements in operational efficiency, safety metrics, and overall innovation within the industry. The integration of simulation tools that deliver real-world performance predictions has allowed shipbuilders to adopt more proactive safety measures and fine-tune their construction processes. This digital transformation has also led to reduced production time and cost, as comprehensive design validations can be conducted long before physical prototypes are constructed. Additionally, these software solutions have enabled a level of precision in manufacturing methods that was previously unattainable, ensuring that every component of a vessel meets the highest standards of quality control.

Implementation and Benefits of Integrated Simulation Tools

Integrated simulation tools have not only streamlined the design process but have also provided vital data that informs every stage of ship construction. By leveraging computational fluid dynamics, finite element analysis, and other advanced modeling techniques, these systems facilitate the early detection of potential design flaws and structural weaknesses. The ability to simulate a ship’s behavior under a variety of operating conditions—ranging from calm seas to extreme weather scenarios—allows designers to refine their models and ensure that safety is embedded into the design from the outset. Bulleted benefits of these simulation systems include:

- Enhanced accuracy in predicting vessel performance

- Reduction in rework and costly design iterations

- Improved adherence to international maritime safety standards

- Accelerated time-to-market through optimized design cycles

Conclusion

The history of marine design software is a compelling narrative of technological innovation, strategic evolution, and relentless pursuit of excellence in the shipbuilding industry. From the early days when manual drafting and hand calculations defined the design process, to the modern era of integrated simulation, 3D modeling, and advanced hydrodynamic analysis, every phase of this progression has contributed significantly to how ships are conceptualized, designed, and built. The journey from laborious hand-drawn blueprints to highly automated digital ecosystems has been driven by the need for higher precision, improved efficiency, and enhanced safety standards. Today’s marine design software stands as a testament to the collaborative efforts of industry pioneers, thoughtful software developers, and progressive engineering organizations, whose contributions continue to redefine the boundaries of what is possible in maritime engineering.

Reflection on the Evolution of Marine Design Software and Its Milestones

In reflecting upon the significant milestones encountered along this journey, it becomes evident that every breakthrough—whether it be in the form of the early adoption of CAD, the integration of solid modeling techniques, or the sophisticated implementation of hydrodynamic simulations—represents a fundamental leap forward in the capabilities of shipbuilders. These innovations have not only set new benchmarks in design accuracy but have also reshaped the industry’s approach to project management, quality control, and risk mitigation. The critical contributions from major industry players and dedicated pioneers have collectively propelled this field into an era where ships can be built faster, safer, and with a higher degree of innovation than ever before. As the digital landscape continues to evolve, so too does the potential for further advancements that will undoubtedly lead to even more efficient and robust design processes in the future.

Future Outlook: Emerging Trends and Potential Technological Advancements

Looking ahead, the field of marine design software is anticipated to further evolve as emerging trends and technologies continue to reshape the design process. Future advancements are expected to integrate even more sophisticated simulation frameworks, utilization of artificial intelligence and machine learning algorithms for predictive analysis, and increasingly robust interoperability between various marine engineering systems. As new computational methods and hardware capabilities become available, the potential for real-time, fully integrated environments that simulate every aspect of vessel performance grows exponentially. These emerging trends signify not only an enhancement of current practices but also hint at the possibility of revolutionary approaches that might one day redefine the fundamental parameters of marine design. Designers and engineers will likely be able to harness these improved tools to create designs that are not just efficient and safe, but also remarkably innovative in terms of aesthetics and functionality.

Also in Design News

Cinema 4D Tip: Scene‑Referred Color Grading Workflow with ACES and 32‑bit EXR

February 05, 2026 2 min read

Read More

Revit Tip: Consistent Sheet Layouts with View Templates, Scope Boxes and Guide Grids

February 05, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …