Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

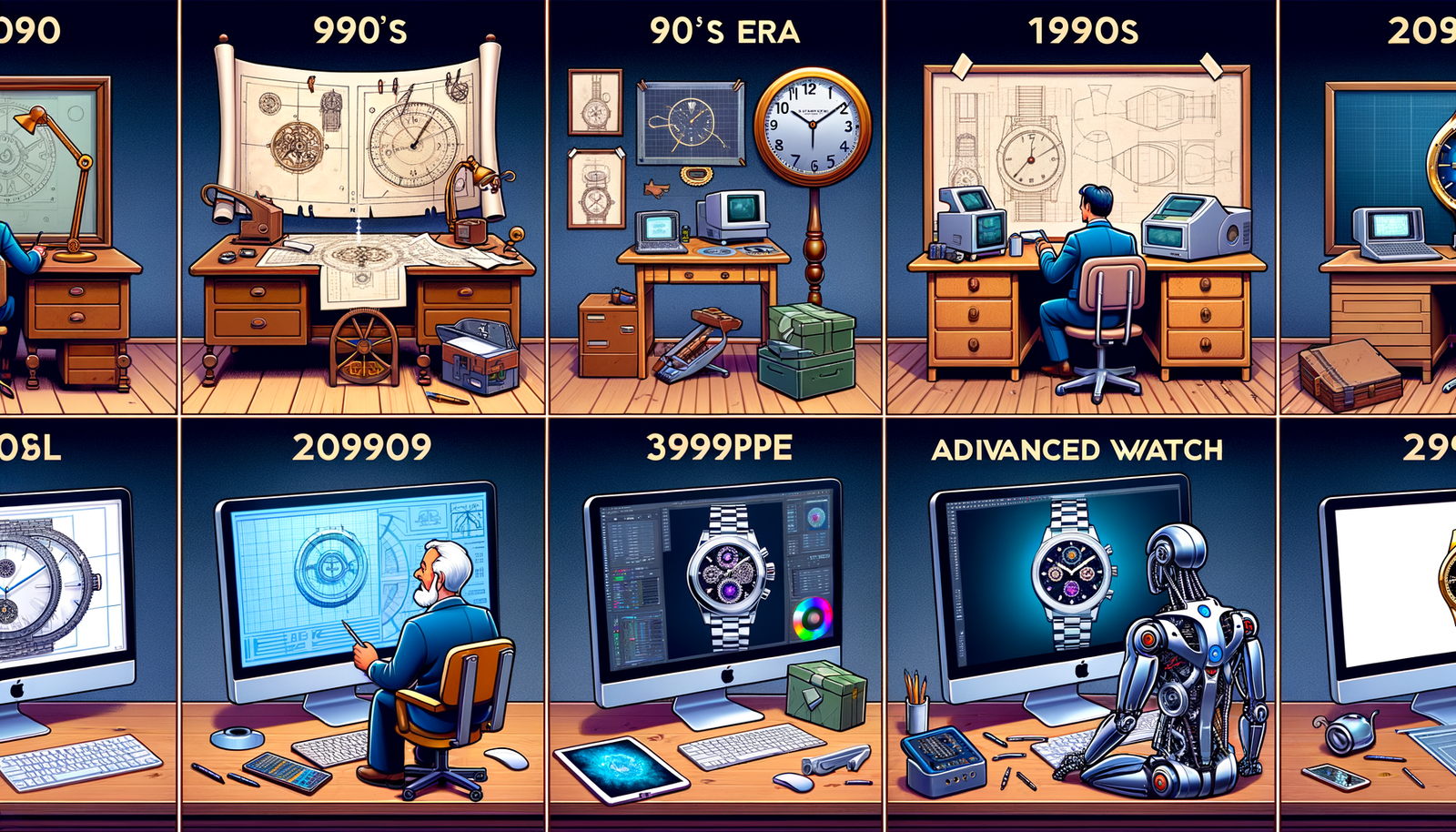

Design Software History: The Evolution of Design Software in the Watchmaking Industry: From CAD to AI and Beyond

September 07, 2024 3 min read

Introduction to Design Software in Watchmaking

The watchmaking industry, renowned for its blend of precision and aesthetics, has undergone a tremendous evolution. Transitioning from the era of traditional handcrafting, where artisans meticulously crafted each component, to modern design techniques powered by advanced software, the industry has continually adapted to technological advancements.

Early watch designers faced substantial challenges, primarily due to the intricate nature of watch components and the necessity for precision. Influenced heavily by mechanical engineering principles, solutions began to emerge that addressed these initial limitations, allowing for more accurate and efficient design processes.

Pioneering Software in Watch Design

Early Adoption of CAD

The introduction of Computer-Aided Design (CAD) in the 1980s marked a significant milestone in watch design. Leading companies such as PTC with their software Pro/ENGINEER and Dassault Systèmes with CATIA pioneered the use of CAD in watchmaking. These tools provided designers with the ability to create detailed and precise models, thus revolutionizing the design process.

Key Figures and Innovators

The early adoption of CAD in watchmaking can be attributed to several notable engineers and designers who drove the industry's transformation. Their contributions laid the foundation for many modern techniques and tools used today. Through their innovative designs, these pioneers showcased the potential of CAD software in creating intricate and aesthetically pleasing timepieces.

Evolution of Design Techniques and Tools

Advancements in Solid and Surface Modeling

The evolution from simple 2D sketches to complex 3D models was a game-changer for the watchmaking industry. Solid modeling software such as SolidWorks and Autodesk Inventor played a crucial role in this transition. These software tools allowed designers to create highly detailed and accurate representations of watch components, facilitating better visualization and refinement of designs.

Integration of Simulation and Finite Element Analysis (FEA)

Another significant advancement in watch design was the integration of simulation and Finite Element Analysis (FEA). Software like ANSYS and COMSOL enabled designers to predict the durability and performance of watch components under various conditions. This capability was especially important for ensuring the reliability and longevity of high-end timepieces.

Parametric and Generative Design

With the rise of parametric design tools such as Siemens NX, the watchmaking industry saw a shift towards more flexible and innovative design approaches. Parametric design allows for the creation of models that can be easily adjusted by changing specific parameters. Generative design, a more recent development, leverages algorithms to generate optimized designs based on predefined criteria, pushing the boundaries of creativity and functionality.

Modern Innovations and Future Directions

Additive Manufacturing and Prototyping

The advent of additive manufacturing, commonly known as 3D printing, has had a profound impact on watch design and production. Companies like Stratasys and Formlabs have led the way in providing cutting-edge 3D printing solutions. This technology enables rapid prototyping, allowing designers to quickly produce and test physical models of their designs before committing to full-scale production.

Virtual and Augmented Reality

Virtual Reality (VR) and Augmented Reality (AR) have become invaluable tools for design visualization and client presentations. These immersive technologies offer a new way to experience and interact with watch designs, providing a more comprehensive understanding of the final product. VR/AR applications have transformed how designers communicate their ideas and receive feedback.

Artificial Intelligence and Machine Learning

The implementation of Artificial Intelligence (AI) and Machine Learning (ML) in watchmaking is an emerging trend that promises to optimize both design and manufacturing processes. AI algorithms can analyze vast amounts of data to identify patterns and suggest improvements, while ML models can continuously learn and adapt to enhance design efficiency. These technologies hold great potential for future innovation in the industry.

Conclusion

Summary of Key Developments

The journey from traditional handcrafting to digital design in the watchmaking industry has been marked by numerous major milestones. From the early adoption of CAD to the integration of advanced simulation and the introduction of AI, each development has played a crucial role in shaping the industry. These advancements have not only improved the precision and efficiency of watch design but have also opened up new possibilities for creativity and innovation.

Looking Ahead

As we look to the future, several trends are likely to continue influencing the watchmaking industry. The ongoing development of generative design and AI-driven optimization will further enhance the capabilities of design software. However, challenges remain, particularly in balancing technological advancements with traditional craftsmanship. The industry will need to navigate these challenges to fully realize the potential of modern design software while preserving the artistry that defines watchmaking.

Also in Design News

Rhino 3D Tip: Rhino Material Optimization: Nesting, Lightweighting, and Cut-Length Reduction

December 31, 2025 2 min read

Read More

Design Software History: Constraint Solving in CAD: From Sketchpad to Modern Parametric Engines

December 31, 2025 12 min read

Read More

Intent-Aware Scan-to-BRep: Integrating LiDAR Point Clouds into Solid Modeling Pipelines

December 31, 2025 12 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …