Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Design Software History: Robotics Revolutionizing Design: Historical Advances, Key Technologies, and Future Trends

June 05, 2024 5 min read

Introduction to Robotics in Design Processes

Robotics in design processes encompasses the integration of robotic systems to enhance and automate various stages of design and manufacturing. This convergence aims to streamline workflows, reduce human error, and achieve higher precision in design outputs. The significance of automation in design cannot be overstated; it has revolutionized industries by enabling more complex, reliable, and faster production cycles.

Historically, the early adoption of robotics in industrial settings laid the groundwork for its eventual influence on design processes. The initial phases saw robotics primarily used for labor-intensive and repetitive tasks in manufacturing sectors such as automotive and electronics. As the technology evolved, its applications expanded, leading to key milestones in the integration of robotics with design software. These advancements have propelled the industry into an era where robots are not just tools but integral components of the design process.

Key Technologies and Innovations

Robotic Design Tools

In the realm of robotic design tools, several technologies have become pivotal. Robotic arms, for example, are extensively used for tasks ranging from material handling to precision assembly. These robotic arms are often integrated with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems, creating a seamless workflow from design to production. CNC (Computer Numerical Control) machining is another critical technology that leverages robotics for precise cutting, milling, and shaping of materials.

Some of the most significant innovations in this domain include autonomous design and fabrication robots. These robots can independently execute design and manufacturing tasks based on predefined parameters and real-time data inputs. Such advancements have transformed traditional manufacturing processes, enabling more dynamic and adaptive production environments.

Software Development

The development of design software has evolved significantly to accommodate the growing integration of robotics. Leading software platforms like SolidWorks, Autodesk, and Rhino have developed specialized modules that facilitate robotic design automation. These platforms offer comprehensive toolsets that enable designers to create, simulate, and optimize robotic workflows within a unified environment.

For instance, SolidWorks provides robust support for robotic kinematics and dynamics, allowing users to model and simulate complex robotic motions. Autodesk's Fusion 360 integrates design, engineering, and manufacturing workflows, offering advanced features for robotic path planning and toolpath generation. Rhino, with its Grasshopper plugin, enables parametric design and algorithmic modeling, which are essential for creating intricate robotic designs.

AI and Machine Learning Integration

The role of Artificial Intelligence (AI) in enhancing robotic design capabilities is becoming increasingly prominent. AI-driven algorithms can optimize design parameters in real-time, reducing the need for iterative testing and prototyping. Machine learning applications in automated design processes have also shown great promise. These applications can analyze vast datasets to identify patterns and predict outcomes, leading to more efficient and innovative design solutions.

Examples of AI and machine learning in this context include generative design, where AI algorithms generate a multitude of design alternatives based on specified criteria. This approach allows designers to explore a broader design space and identify optimal solutions that might not be immediately apparent through traditional methods.

Pioneers and Companies in Robotic Design Automation

Influential Companies

Several companies have played pivotal roles in advancing robotic design automation. ABB Robotics, KUKA, and FANUC are among the leading manufacturers of industrial robots, each contributing unique technologies and solutions to the field.

ABB Robotics is renowned for its collaborative robots and advanced control systems, enabling seamless integration with various design software platforms. KUKA's robots are celebrated for their precision and versatility, making them ideal for a wide range of design and manufacturing applications. FANUC's expertise in CNC and robotic automation has set industry standards, particularly in high-precision and high-speed manufacturing environments.

In the realm of design software, Autodesk and Dassault Systèmes have been instrumental in developing robotic-friendly design tools. Autodesk's suite of software, including AutoCAD and Fusion 360, provides comprehensive support for robotic design and simulation. Dassault Systèmes' CATIA and SOLIDWORKS platforms offer advanced capabilities for robotic kinematics, dynamics, and control, facilitating the creation of sophisticated robotic systems.

Notable Individuals

The contributions of key figures in the field of robotics and design software cannot be overlooked. Rodney Brooks, a pioneering roboticist, has significantly influenced the development of intelligent robots through his work at MIT and iRobot. His research on behavior-based robotics laid the foundation for many modern robotic systems.

John Walker, the co-founder of Autodesk, played a crucial role in the development of CAD software that integrates with robotic systems. His vision and leadership helped establish Autodesk as a leader in the field of design automation.

Contemporary innovators continue to advance the field, bringing fresh perspectives and groundbreaking technologies to the forefront. Their contributions are shaping the future of robotic design automation, paving the way for more intelligent, efficient, and adaptable systems.

Impact and Future Trends

Impact on Various Industries

The impact of robotics in design processes is evident across various industries. In the automotive sector, robots are used for tasks such as welding, painting, and assembly, leading to significant improvements in efficiency and quality. In aerospace, robotic systems are employed for precision manufacturing and inspection, ensuring high standards of safety and reliability.

The architecture industry has also benefited from robotic design automation. Robots are used for tasks such as 3D printing of structural components, enabling the construction of complex and customized designs. The benefits of robotics in these industries include increased efficiency, precision, and innovation in design.

Future Prospects

The future of robotics in design processes is promising, with emerging trends such as collaborative robots (cobots) gaining traction. Cobots are designed to work alongside humans, enhancing their capabilities and efficiency. These robots are equipped with advanced sensors and AI algorithms, enabling them to safely and effectively collaborate with human operators.

Predictions for the future integration of robotics in design software and processes include the development of more intuitive and user-friendly interfaces, enabling designers to interact with robotic systems more seamlessly. Advances in AI and machine learning will further enhance the capabilities of robotic design tools, enabling more sophisticated and adaptive systems.

Challenges and Opportunities

Despite the numerous benefits, the adoption of robotics in design processes is not without its challenges. Technical challenges include the development of robust and reliable robotic systems that can operate in dynamic and unstructured environments. Ethical challenges also arise, particularly concerning the impact on employment and the need for responsible AI.

However, these challenges also present opportunities for future advancements and interdisciplinary collaborations. Researchers, engineers, and designers must work together to address these challenges, leveraging their expertise to create innovative solutions that advance the field of robotic design automation.

In conclusion, the history of design software and its integration with robotics is a fascinating journey of technological evolution and innovation. From the early adoption of robotics in industrial settings to the development of advanced AI-driven design tools, the field has seen remarkable advancements. Key contributors, both individuals and companies, have played pivotal roles in shaping the future of robotic design automation, and the impact of these technologies is evident across various industries. The future holds immense potential for further integration and innovation, paving the way for more intelligent, efficient, and adaptive design processes.

Also in Design News

Rhino 3D Tip: Validate Curvature and Surface Fairness in Rhino

December 15, 2025 2 min read

Read More

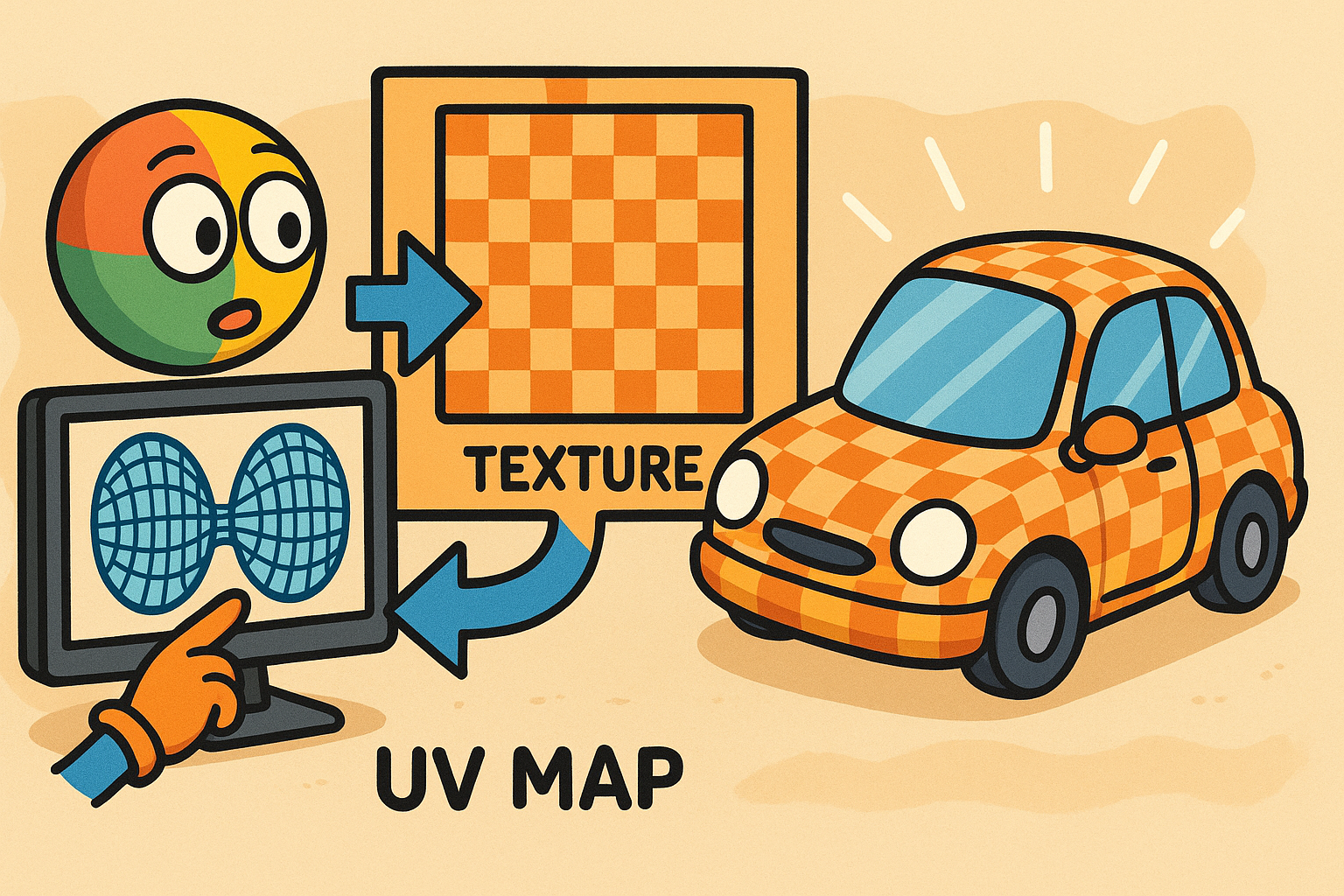

Design Software History: UV Mapping and Texture Pipelines: From Parameter Spaces to Product Visualization

December 15, 2025 11 min read

Read More

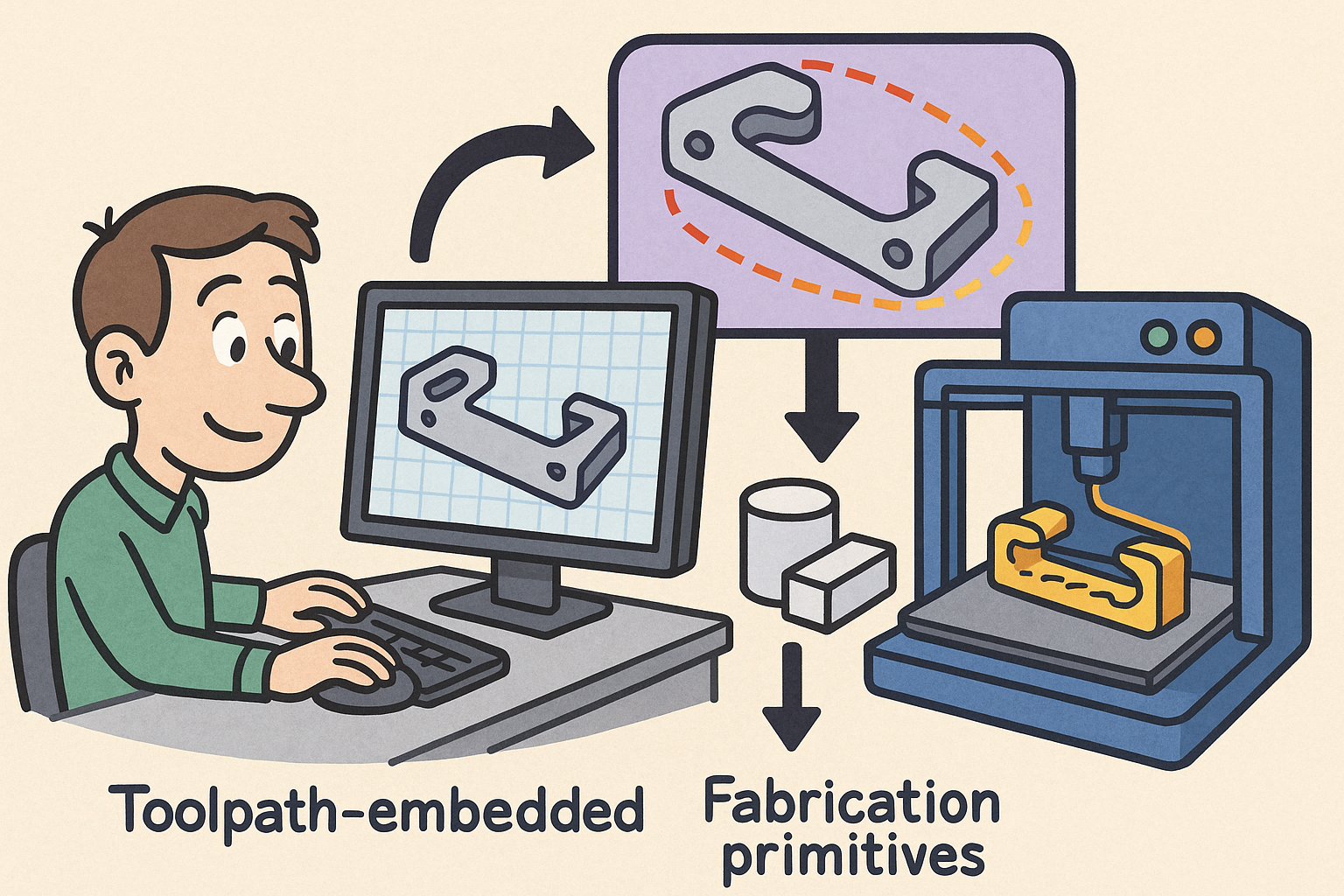

Path-First Modeling: Embedding Toolpath-Aware Constraints and Fabrication Primitives into CAD Kernels

December 15, 2025 13 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …