Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

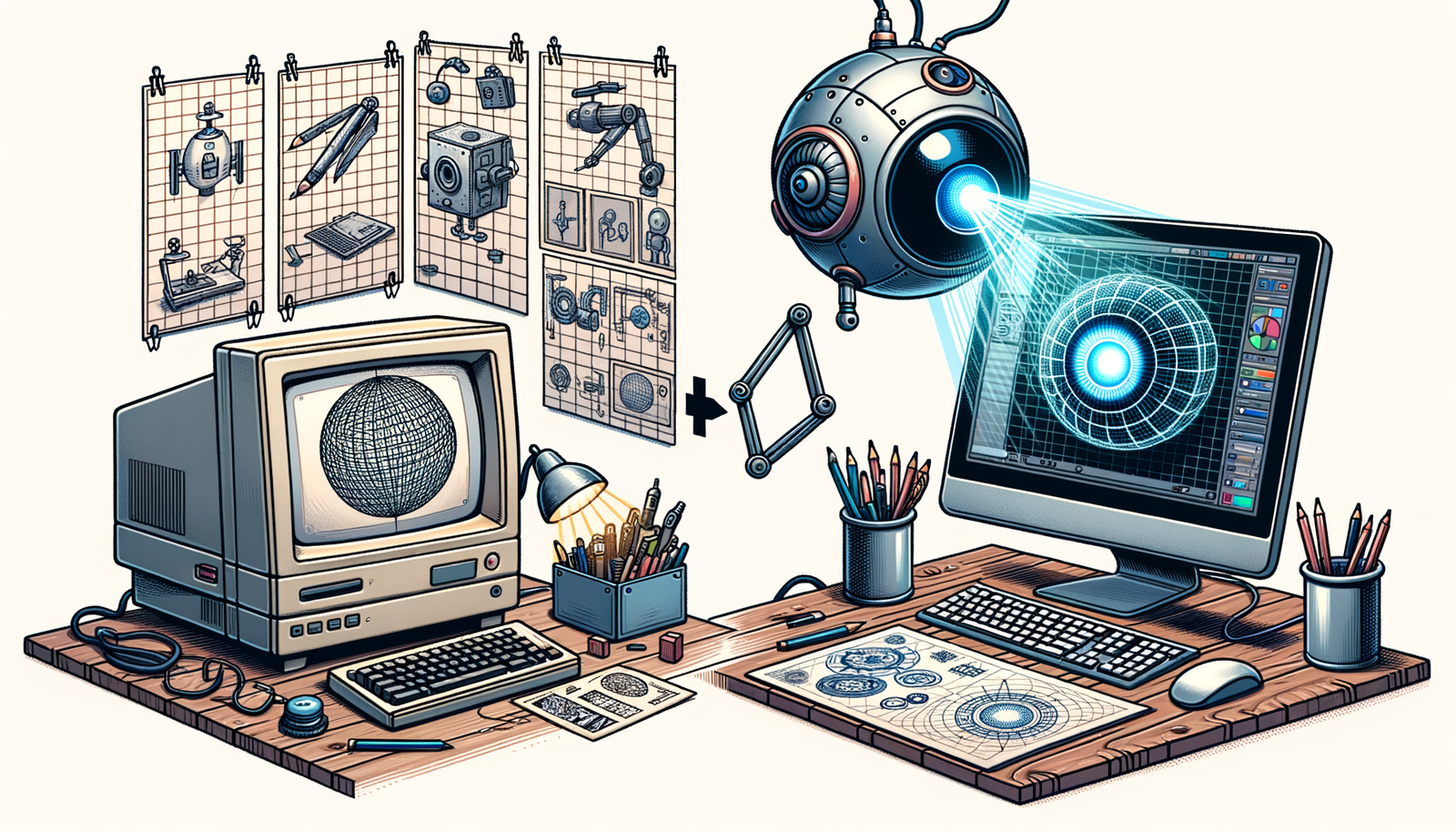

Design Software History: Machine Vision's Transformative Role in the Evolution of Design Software

August 29, 2024 6 min read

Introduction to Machine Vision and Its Relevance in Design Software

Machine vision is a field of computer science and engineering that enables machines to interpret and understand visual data from the surrounding environment. This technology has rapidly evolved from basic image processing to sophisticated systems capable of performing complex tasks with high accuracy. As design software continues to advance, machine vision plays an increasingly vital role in enhancing various design processes across multiple industries.

Definition and Overview

What is machine vision?

Machine vision, also known as computer vision, involves the use of cameras, sensors, and software algorithms to capture and analyze visual information. This technology enables machines to "see" and interpret images or videos, allowing them to perform tasks such as object detection, classification, and scene reconstruction.

Brief history and evolution of machine vision technology

The origins of machine vision can be traced back to the 1960s when researchers began exploring the possibility of using computers to process visual data. Early efforts focused on simple image processing techniques, such as edge detection and pattern recognition. Over the decades, advancements in hardware, software, and artificial intelligence have propelled machine vision into a critical technology for various applications, including design software.

Importance in Design Software

How machine vision integrates into the design process

Machine vision seamlessly integrates into the design process by providing real-time analysis and feedback. This integration enhances precision, efficiency, and automation in various design tasks. For instance, in computer-aided design (CAD) and computer-aided manufacturing (CAM), machine vision can automate quality control, detect defects, and ensure that designs meet stringent specifications.

Initial applications and breakthroughs

Several breakthroughs in machine vision technology have paved the way for its adoption in design software. Early applications included automated inspection systems in manufacturing, where machine vision was used to detect defects and ensure product quality. Over time, the technology has evolved to support more complex design tasks, such as 3D modeling, virtual reality, and augmented reality, significantly enhancing the capabilities of design software.

Core Technologies and Mathematical Models Underpinning Machine Vision

Core Technologies

Image processing techniques

Image processing techniques are fundamental to machine vision. These techniques involve the manipulation and analysis of digital images to extract meaningful information. Key image processing methods include:

- Edge detection: Identifying the boundaries of objects within an image.

- Pattern recognition: Recognizing specific patterns or features in an image.

- Image segmentation: Dividing an image into regions or segments for further analysis.

Artificial intelligence and neural networks in machine vision

Artificial intelligence (AI) and neural networks have revolutionized machine vision by enabling machines to learn from data and improve their performance over time. Convolutional neural networks (CNNs), a type of deep learning model, are particularly effective in image recognition tasks. These neural networks can automatically learn to identify features and patterns in images, making them invaluable for complex design applications.

Hardware advancements

Advancements in hardware have also played a crucial role in the development of machine vision technology. High-resolution cameras, sensors, and powerful processing units enable the capture and analysis of detailed visual information. Innovations in hardware have significantly increased the speed and accuracy of machine vision systems, making them more suitable for demanding design applications.

Mathematical Models

Algorithms and computational models used in machine vision

Underlying many machine vision systems are sophisticated algorithms and computational models that process visual data. These include:

- Convolutional neural networks (CNNs): Deep learning models designed for image recognition tasks.

- Support vector machines (SVMs): Supervised learning models used for classification and regression.

- Random forests: Ensemble learning methods that combine multiple decision trees to improve accuracy.

The role of geometric modeling and 3D reconstruction

Geometric modeling and 3D reconstruction are critical components of machine vision in design software. Geometric modeling involves the mathematical representation of objects in 3D space, while 3D reconstruction refers to the process of creating a 3D model from 2D images. These techniques enable designers to visualize and manipulate complex objects with high precision.

Applications and Impact on Various Design Domains

Product Design and Manufacturing

Automated quality control and defect detection

In product design and manufacturing, machine vision is widely used for automated quality control and defect detection. Machine vision systems can inspect products at various stages of production, identifying defects and ensuring that specifications are met. This automation enhances efficiency, reduces waste, and improves overall product quality.

Enhancing precision and efficiency in CAD/CAM systems

Machine vision also enhances precision and efficiency in CAD/CAM systems. By providing real-time feedback and analysis, machine vision enables designers to create more accurate and detailed models. This integration streamlines the design process, reduces errors, and accelerates the development of complex products.

Architectural and Construction Design

Real-time site monitoring and progress tracking

In architectural and construction design, machine vision is used for real-time site monitoring and progress tracking. Cameras and sensors monitor construction sites, capturing visual data that is analyzed to track progress, detect issues, and ensure compliance with design plans. This technology enhances project management and improves safety on construction sites.

Integration with Building Information Modeling (BIM) for enhanced visualization

Machine vision is also integrated with Building Information Modeling (BIM) to enhance visualization and collaboration in architectural design. BIM involves the creation of detailed 3D models of buildings, which are used for planning, design, and construction. Machine vision systems can capture and analyze visual data from construction sites, updating the BIM models in real-time and providing accurate visualizations for stakeholders.

Medical and Biomedical Design

Applications in medical imaging and diagnostics

Machine vision has significant applications in medical imaging and diagnostics. Advanced image processing techniques enable the analysis of medical images, such as X-rays, MRIs, and CT scans, to detect abnormalities and diagnose conditions. This technology improves the accuracy and speed of medical diagnoses, leading to better patient outcomes.

Design and manufacturing of medical devices using machine vision

Machine vision is also used in the design and manufacturing of medical devices. By providing precise measurements and real-time feedback, machine vision systems ensure that medical devices meet strict regulatory standards and are safe for use. This technology enhances the design process, reduces errors, and accelerates the development of innovative medical devices.

Pioneers, Companies, and Future Directions

Key Players and Innovators

Companies leading the integration of machine vision in design software

Several companies have played a pivotal role in integrating machine vision into design software. Siemens and Autodesk are among the leaders in this field, developing advanced machine vision solutions that enhance various design processes. These companies invest heavily in research and development, driving innovation and setting industry standards.

Notable individuals contributing to the field

Numerous individuals have made significant contributions to the field of machine vision. Researchers, engineers, and entrepreneurs have developed groundbreaking technologies and algorithms that underpin modern machine vision systems. Their work has paved the way for the widespread adoption of machine vision in design software.

Future Trends and Challenges

Emerging trends in machine vision technology

The future of machine vision technology is marked by several emerging trends. These include the integration of AI and machine learning, the development of more advanced sensors and cameras, and the use of augmented reality (AR) and virtual reality (VR) in design applications. These trends promise to further enhance the capabilities of machine vision and expand its applications in design software.

Potential challenges and limitations in widespread adoption

Despite its advancements, machine vision technology faces several challenges and limitations. These include the need for large datasets for training AI models, the complexity of integrating machine vision systems with existing design software, and concerns about privacy and security. Addressing these challenges will be crucial for the widespread adoption of machine vision in design software.

Predictions for the future impact of machine vision on design software

Looking ahead, machine vision is expected to have a profound impact on design software. As technology continues to evolve, machine vision will enable more precise, efficient, and automated design processes. This will lead to the creation of innovative products, improved architectural and construction practices, and advancements in medical and biomedical design. The future of design software is undoubtedly intertwined with the ongoing development of machine vision technology.

Also in Design News

Subscribe

Sign up to get the latest on sales, new releases and more …