Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Design Software History: Historical Development of Additive Manufacturing and Its Integration with Design Software Technologies

September 18, 2025 10 min read

Historical Context and the Emergence of Additive Manufacturing

The evolution of additive manufacturing has its roots in early experiments and theoretical concepts that emerged during the latter half of the twentieth century. Designers and engineers began to challenge the limitations of traditional subtractive processes by exploring ways in which materials could be deposited layer by layer, leading to entirely new fabrication possibilities. In the early days, concepts such as laminate object manufacturing and rapid prototyping started to take shape. These innovative ideas, fueled by advancements in electronics and mechanics, laid the groundwork for what we now consider additive manufacturing. Early computer-aided design (CAD) tools were integral to this process, as they allowed designers to create detailed digital models that could be interpreted by machines. Pioneering software tools enabled the translation of these models into machine-readable instructions, a critical step that bridged the gap between traditional design methods and digital fabrication.

Early Additive Manufacturing Concepts and Processes

In the beginning, research in additive manufacturing was often the result of interdisciplinary collaboration, combining insights from computer science, mechanical engineering, and material science. This period was marked by experimental techniques and innovative methodologies that prioritized precision and rapid iteration. Some of the pioneering concepts included the deposition of thermoplastics and similar composite materials that could be layered to form complex geometries. Key attributes that defined these early processes were flexibility and adaptability, and these innovations quickly became known for their ability to reduce both production costs and material waste. Educators and industry leaders alike began to see the potential for these techniques to revolutionize product design and manufacturing. Important contributions were made not only by industrial entities but also by academic institutions, which laid the theoretical groundwork for what eventually evolved into mainstream additive manufacturing technologies.The Role of Early Computer-Aided Design Tools

Early CAD systems played a transformative role by enabling engineers to convert ideas into powerful digital representations. These systems, developed during the 1960s and 1970s, evolved from simple drafting tools into sophisticated software capable of modeling three-dimensional objects with high precision. Before the advent of these tools, designers were constrained by traditional pen-and-paper methods that lacked the flexibility required for modern engineering challenges. The digital revolution in design introduced by these CAD applications allowed for rapid modifications, intricate detailing, and improved collaboration across different engineering disciplines. The integration of computer-assisted design with additive manufacturing created a paradigm shift; it allowed for the realization of objects that were previously impossible to manufacture using conventional processes. This synergy between CAD and emerging fabrication techniques not only improved design accuracies but also delivered faster turnaround times from conception to final production. It also introduced robust simulation capabilities that helped in predicting potential issues with materials or design geometries before the actual manufacturing process began.Key Milestones in Bridging Traditional Design Software and Additive Manufacturing Needs

Several milestones have been crucial in bridging the traditional design software paradigms with the practical requirements of additive manufacturing. These milestones include the development of integrated software platforms that allow seamless transitions from digital design to physical production. Some notable milestones include the invention of stereolithography in the 1980s, which showcased the precision possible when combining digital data with material deposition. Over time, advances in scanning technologies, digital modeling, and real-time simulation further deepened the integration between design software and manufacturing processes. As computational power increased, CAD systems became more capable, and algorithms evolved to handle more complex tasks such as optimizing material usage and simulating structural integrity under various conditions. The development of specialized file formats and standardized protocols facilitated improved communication between different software and hardware. In addition, these milestones enabled designers to create highly intricate structures, supporting a wide range of industries from aerospace to medical applications. This evolution has been fundamentally marked by strategic decisions made by tech pioneers and software companies who recognized the potential in merging design with production, setting the stage for the explosive growth of additive manufacturing in subsequent decades.The Software Foundations Behind Additive Manufacturing

The software that drives additive manufacturing is built upon decades of research in computational geometry, numerical methods, and simulation algorithms. The evolution of these computational techniques has played a central role in enabling 3D printing and digital fabrication. Early algorithms were designed with the sole purpose of converting complex three-dimensional models into layered instructions that manufacturing machines could interpret. These algorithms needed to account for various factors such as material properties, thermal expansion, and structural integrity, leading to increasingly sophisticated software solutions over time. Key algorithms in use today include slicing, which divides a 3D model into a series of horizontal layers; toolpath generation, which defines the path a printer’s nozzle takes to deposit material; and real-time simulation algorithms that monitor production accuracy. In the realm of engineering computation, mathematical processing capabilities enabled algorithms to simulate physical and chemical properties with high accuracy. The integration of these algorithms within specialized software platforms has resulted in robust systems that allow for the rapid iteration and validation of design models. As a consequence, technological refinements have rapidly spurred the broader adoption and further improvement of additive manufacturing processes.

Advancements in Computational Geometry and 3D Modeling Techniques

One of the key drivers of progress in additive manufacturing software is the evolution of computational geometry and 3D modeling techniques. These advancements have allowed design software to process and generate complex geometric shapes that were once considered unattainable. Early CAD systems primarily focused on simple shapes, but as computational power grew, the need for more effective and efficient algorithms became apparent. Enhanced modeling techniques can now capture the nuances of organic forms as well as intricate mechanical components. Such detailed representations are crucial not only for aesthetic appeal but also for ensuring functional reliability in critical applications. A variety of methodologies—such as constructive solid geometry (CSG) and boundary representation (B-rep)—have been employed to cater to the unique demands of different industries. As these techniques matured, they laid the groundwork for further integration with machine learning algorithms and real-time simulation processing, leading to smarter and more intuitive design environments.Core Algorithms and Their Integration with Hardware Advancements

The evolution of core algorithms such as slicing, toolpath generation, and simulation has been paramount to enabling precise and efficient manufacturing. Slicing algorithms work by converting a three-dimensional model into discrete layers, ensuring that each layer is properly prepared for the printing process. In tandem with toolpath generation, these algorithms effectively transform digital models into a series of machine instructions, optimizing the tool's traversal path for maximum efficiency and minimum print time. Real-time simulation algorithms further ensure that the physical process adheres closely to digital designs by predicting possible errors, optimizing energy consumption, and enabling pre-emptive quality control. Software developers have increasingly integrated these computational tools with rapidly evolving hardware, facilitating a seamless synergy that accelerates printing speed, precision, and reliability. This integration is also characterized by a continuous feedback loop, where hardware challenges inspire further algorithmic refinements, and these software optimizations, in turn, allow for the exploitation of more sophisticated hardware capabilities. Through this constant interplay, a robust framework has been established that has ultimately redefined the parameters of digital fabrication.Influence of Mathematical Models and Engineering Computation

Mathematical models have long served as the backbone of additive manufacturing software. From the early days of numerical analysis to today’s complex simulations, computational methods have been pivotal in ensuring dimensional accuracy and material precision. These models rely on differential equations and finite element analysis to predict how a part will behave once printed and under various loads. By incorporating these models into simulation algorithms, engineers can forecast stress distribution, thermal gradients, and other critical aspects that influence the final product. Engineering computation and mathematical modeling have also significantly affected how software optimizes design structures. A deep understanding of geometrical transformations, interpolation methods, and error minimization techniques has enabled the creation of software that not only designs but also validates the integrity of the prototype before it ever reaches the production stage. Through the application of these advanced mathematical tools, engineers can improve overall product performance and reduce the risk of failure, ensuring that each layer of material—literal and figurative—is perfectly aligned with the intended design.Pioneers, Companies, and Technological Milestones

In the expansive history of design software and its subsequent impact on additive manufacturing, several pioneers and companies have left an indelible mark. Early innovators were often researchers and academics who foresaw the potential of combining computer-aided design with emerging fabrication techniques. Their work established the conceptual frameworks that later enabled companies to develop sophisticated design tools and manufacturing processes. Among the key players that emerged during this period, companies such as Autodesk and Dassault Systèmes have been especially influential in shaping the field with revolutionary software products. These companies not only refined existing design methodologies but also introduced novel concepts that bridged the gap between pure digital design and practical, on-the-ground manufacturing needs. Their innovative software releases helped set industry standards, such as the development of file formats aimed at ensuring smooth data transfer between design and production platforms. With a steady focus on research and development, these companies have continued to adapt and respond to emerging trends, ensuring that their software remains at the cutting edge of both design and fabrication technology.

Contributions by Early Innovators and Design Software Experts

Early innovators in the field of design software were instrumental in establishing a reliable foundation for modern additive manufacturing. Engineers, mathematicians, and computer scientists collaborated to derive algorithms that could effectively transform complex design data into actionable commands. Their work was defined by rigorous experimentation and a visionary approach to problem-solving. From devising initial prototypes to presenting refined software solutions, these experts demonstrated how cohesive collaboration between academic theory and industrial application can drive technological breakthroughs. The legacy of these pioneers is evident in how contemporary design software operates. Today’s tools are imbued with many of the core principles established by these early leaders, including modularity, interoperability, and precision. The cumulative knowledge gleaned from decades of research has empowered modern innovators to further push the boundaries of what digital fabrication can achieve, ensuring that every step in the design and manufacturing process is as refined as possible.Company Highlights and Their Impact on Additive Manufacturing

Numerous companies have made seminal contributions by offering dedicated software platforms that have significantly influenced the trajectory of additive manufacturing. Autodesk stands out for its early adoption of CAD advancements and its efforts to integrate simulation culture with design workflows. Likewise, Dassault Systèmes is renowned for its pioneering work in 3D modeling and simulation which reshaped how products are conceptualized and brought to life. Other major industry players have also introduced solutions that have streamlined additive manufacturing, emphasizing the importance of user-friendly interfaces and robust computational capabilities. A review of the evolution of these solutions reveals a series of technological milestones that have collectively advanced the field:- Introduction of comprehensive design environments that incorporate both creative and engineering perspectives.

- Launch of software solutions capable of real-time simulation and material stress analysis.

- Development of platforms that allow for seamless integration between design files and manufacturing hardware.

- Implementation of robust data management systems to support collaborative design efforts across distributed teams.

Collaborations Between Academia and Industry

An equally important aspect of the technological breakthrough witnessed in additive manufacturing is the **collaboration between academia and industry**. Universities, research institutions, and industrial research labs have worked in tandem to explore new frontiers in materials science, computational geometry, and high-performance computing. These partnerships enabled a continuous feedback loop that accelerated the pace of innovation. Academic research contributed advanced theories and proofs-of-concept that were later translated into practical algorithms by the industry. In parallel, industrial challenges provided real-world testing grounds for academic ideas, thus ensuring they were robust enough for deployment in commercial applications. The synergy that emerged from these collaborations has set a high benchmark for future research endeavors and continues to inspire a new generation of innovators who are dedicated to bridging the gap between theoretical research and practical application.Challenges, Future Trends, and Conclusion

The journey of additive manufacturing from its conceptual origins to its present-day sophistication is not without challenges. Despite the significant progress in design software and digital fabrication technologies, the industry continues to grapple with issues such as material limitations, software interoperability, and user experience. Material constraints often mean that even the most intricate designs must be simplified to avoid failures during production. Furthermore, as the number of software tools continues to rise, ensuring smooth interoperability between different platforms remains an ongoing challenge. This fragmentation can lead to inefficiencies and increased time-to-market for new products. Additionally, user experience, particularly for novices in the field, must be prioritized through intuitive interfaces and comprehensive support systems. These challenges are compounded by rapid technological evolution; as hardware becomes more advanced, software must quickly adapt to manage new functionalities and increased performance demands. Nonetheless, the fundamental strengths of today’s design software have established a robust foundation upon which further innovations can be built.

Emerging Trends in Additive Manufacturing Software

Looking ahead, several trends are poised to redefine additive manufacturing software over the coming years. The integration of AI-driven design is gaining traction, promising enhanced automation and improved optimization in both design and production phases. Real-time simulation is also emerging as a key trend, enabling designers to anticipate defects and improve overall print accuracy while processes are in motion. Cloud-based collaboration tools are set to revolutionize how design teams work remotely, providing centralized data storage that streamlines communications and data sharing. In addition, developments in interoperability promise more seamless transitions between design applications and manufacturing hardware, reducing risk and boosting productivity. Enhanced user interfaces are increasingly being developed to cater to a broader spectrum of users, from seasoned engineers to creative designers new to the technology. The combination of these trends is expected to address many of the current challenges, fostering an environment of accelerated innovation and efficiency.Conclusion and Future Impact of Software Advancements

In conclusion, the evolution of design software for additive manufacturing is a testament to the enduring synergy between technological innovation and creative design. The foundations laid by early CAD pioneers, the continuous refinement of computational geometry and simulation algorithms, and the considerable contributions from industry leaders such as Autodesk and Dassault Systèmes have collectively propelled the field into a mature and dynamic industry segment. The challenges that remain—whether they be material limitations, integration hurdles, or user experience concerns—are being mitigated as new technological advancements steadily overcome these obstacles. Looking into the future, software will not only enable faster and more accurate manufacturing but will also facilitate entirely new ways of thinking about product design and collaboration. As academia and industry continue to work hand in hand, we can expect major leaps forward driven by artificial intelligence, real-time simulation, and enhanced cloud-based collaboration frameworks. Ultimately, the ongoing innovations in design software will continue to catalyze the evolution of manufacturing processes, positively impacting not just industrial production, but the broader landscape of how we conceive, design, and realize the objects that shape our world.Also in Design News

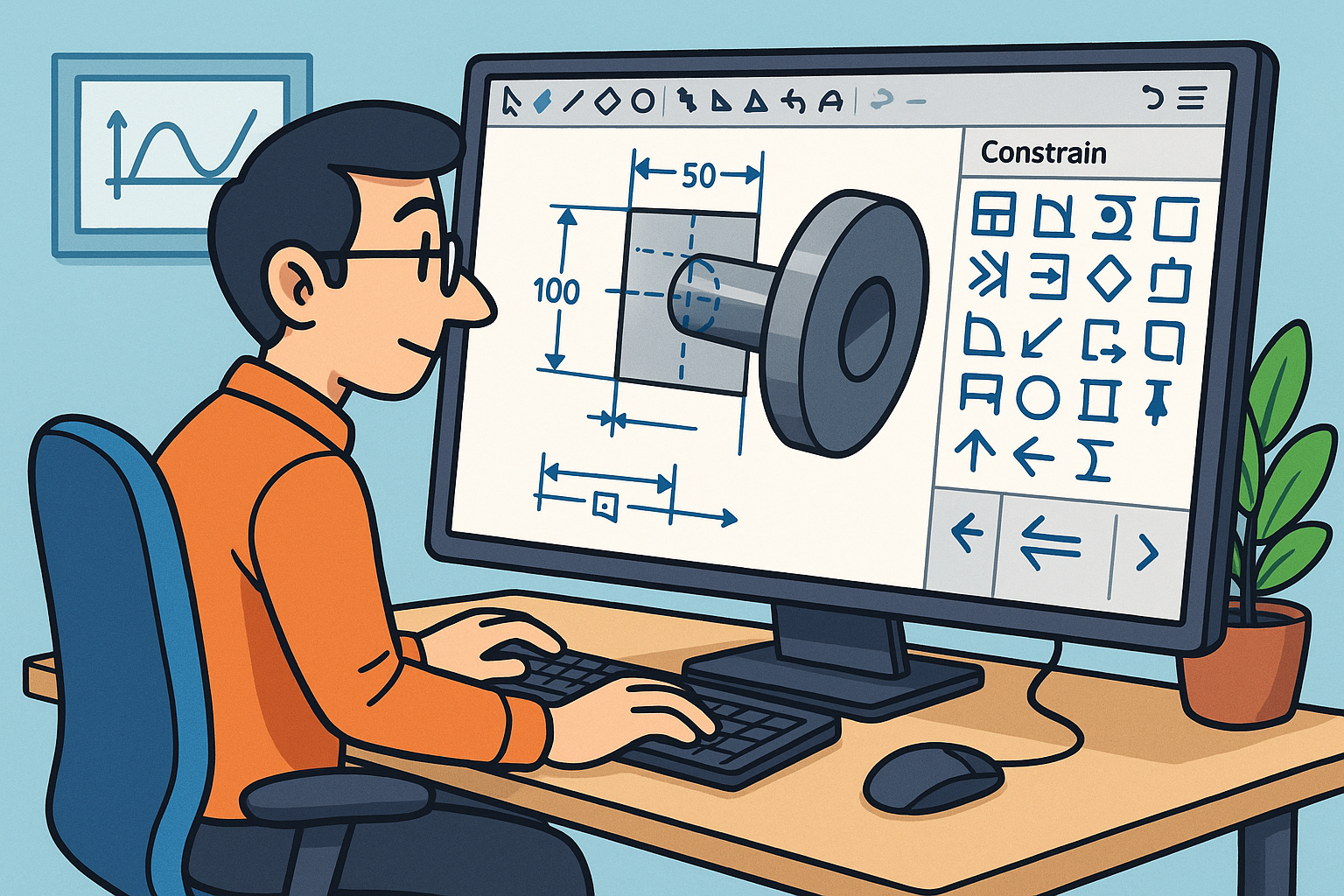

Advanced Parametric Constraints: Revolutionizing Precision in Modern Design Software

September 18, 2025 8 min read

Read More

Cinema 4D Tip: Techniques for Creating Realistic Rock Materials in Cinema 4D

September 18, 2025 3 min read

Read More

Bluebeam Tip: Enhancing PDF Security in Bluebeam Revu: Quick Tips for Protecting Sensitive Files

September 18, 2025 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …