Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Design Software History: From Drafting to Associativity: The Rise of Parametric, Fabrication-Aware Modeling (Mid‑1990s–Late‑2000s)

November 01, 2025 10 min read

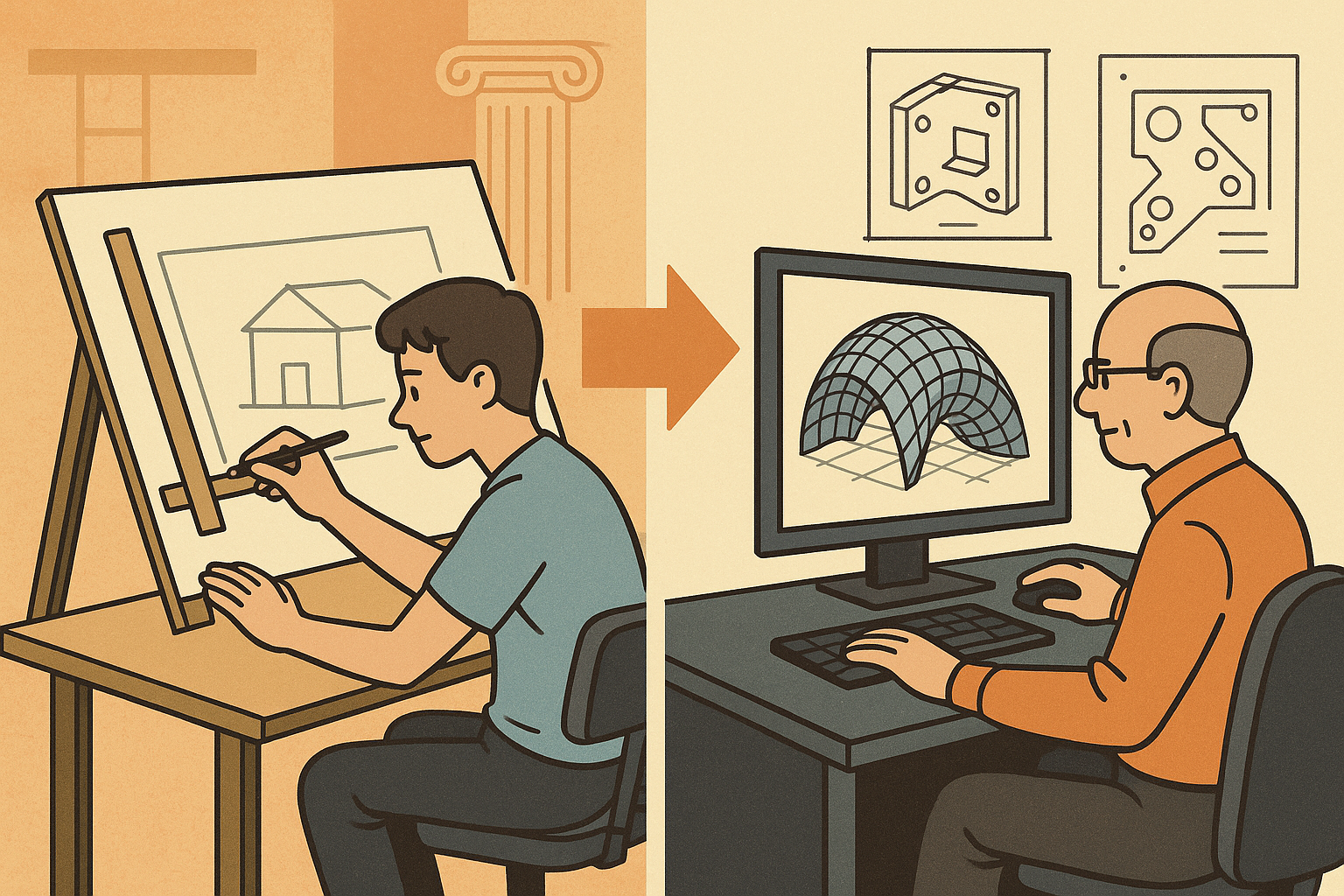

Parametric design did not arrive as a manifesto; it emerged from day-to-day problem solving when architects and engineers began encoding intent as relationships rather than drawings. From the mid‑1990s through the late‑2000s, a cluster of studios, software developers, and engineering collaborators quietly transformed authoring tools, workflows, and expectations about how geometry should behave when changed. That shift—away from static drafting and toward associative, fabrication-aware modeling—gave designers the means to rehearse options quickly, coordinate with partners, and carry constraints to the shop floor. The following account traces the cultural, technical, and organizational moves that made this possible, focusing on the intertwined paths of Zaha Hadid Architects and UNStudio, the SmartGeometry community, and partners at Arup and AKT II. It is a story about software and hardware, but more importantly about people who insisted that geometry be computationally legible, analyzable, and buildable. By the time the decade closed, parametric thinking had become a lingua franca across concept design, engineering exchange, and fabrication, setting foundations for contemporary generative, performance-driven practice.

Context and catalysts (mid-1990s to late-2000s)

Studios and voices reframing authorship

Both Zaha Hadid Architects and UNStudio turned away from the drawing as a terminal artifact and toward rule-based form-making as a way to manage complexity while preserving authorship. At ZHA, Zaha Hadid’s compositional fearlessness coupled with Patrik Schumacher’s systematic emphasis on “parametricism” gave the studio a clear mandate: write intent into the model so that families of options can be explored without redrawing. This meant master sketches, curve hierarchies, and dependency structures became core to the studio’s grammar. UNStudio, under Ben van Berkel and Caroline Bos, framed their practice around organizational systems, foregrounding circulation, sectioning, and material logics as relational networks rather than isolated schemas. Both studios hired designers who were as comfortable with scripts and constraint networks as with pencil and paper, and both pushed their digital teams to maintain associativity from concept to coordination. The shared ethos was not a stylistic preference for curvature; it was a methodological insistence that design variables remain tractable. This implied that a curve drawn for an exhibition rendering could and should be promoted into a controller for reinforcement zones, facade seams, or casting sequences, with tolerances encoded long before the shop drawings.

Industry inflection points and communities of practice

Several converging forces transformed the industry from “surface-as-drawing” to “surface-as-system.” The SmartGeometry group—convened by figures including Robert Aish, Hugh Whitehead, and Lars Hesselgren—was pivotal in bridging practice, research, and software. SmartGeometry’s workshops and conferences created a testing ground where architects, engineers, and developers could prototype features, compare algorithms, and stress-test ideas against real projects. Simultaneously, engineering partnerships normalized algorithmic exchange: at Arup, designers worked with Cecil Balmond and teams adept at custom analysis scripts; AKT II, spearheaded by Hanif Kara and collaborators, pursued parametric structural models that could swallow and return high-fidelity data. The result was a culture of shared computational models rather than a relay of disconnected files. Key inflection points included:

- Associative modeling environments where geometry inherited rules from controllers and constraints.

- Reusable “definitions” or scripts allowing design moves to be replayed, audited, and edited.

- Fabrication-aware detailing woven into early design, shortening the loop between intention and buildability.

- Open dialogues with software vendors—Bentley, McNeel, Autodesk, Dassault Systèmes—accelerating feature development aligned to practice.

Hardware and software backdrop enabling continuity

The technical substrate mattered. Affordable dual‑CPU workstations with Intel Xeon processors, 64‑bit operating systems, and expanding RAM pools removed the ceiling on model size. GPU‑accelerated viewports—via NVIDIA Quadro and ATI FireGL boards—made shaded NURBS and mesh previews fluid enough for interactive iteration. Underneath, robust NURBS implementations supported precise curvature continuity (G1/G2) and stable reparameterization, while polygon and subdivision modeling pipelines offered speed for early sculpting. Crucially, early pipelines to CNC, laser cutting, and complex formwork plugged associative intent into the shop. Router beds and laser cutters in university labs and specialist fabricators turned panelization and nesting from abstractions into daily tasks, making tolerance and material behavior explicit. Networked storage, SVN repositories, and later DVCS systems supported versioning of scripts and master models across distributed teams. The net effect: what once required mainframe-class resources became desk-side, allowing studios to test, fail, and refine in-house. With scripting hooks exposed—MEL in Maya, RhinoScript and later Python in Rhino, VBA and .NET APIs in MicroStation—designers could improvise their own tools. That autonomy, combined with partnerships that expected algorithmic exchanges, normalized a workflow where geometry, metadata, and analysis cohabited from concept through coordination.

Toolchains and techniques that made “parametric” concrete

Core platforms and kernels that shaped practice

Parametric practice coalesced around a few platforms, each bringing specific strengths and biases that shaped workflows. Bentley’s MicroStation paired with GenerativeComponents (GC)—with Robert Aish’s influence prominent in its early conception—offered feature graphs, associative references, and transaction histories woven into a robust CAD backbone. GC made dependency visible: a designer could declare a line as the parent of a surface, set constraints, and replay changes reliably. Rhino, from Robert McNeel & Associates, earned trust for its fast, forgiving NURBS modeling and a scriptable core that evolved from RhinoScript to full Python integration. From 2007 onward, David Rutten’s Grasshopper—framed as “Explicit History”—recast parametric modeling as a visual canvas where nodes produced not just geometry but also control of data trees and iteration. Autodesk’s Maya provided polygon and subdivision freedom with MEL scripting (later Python), making it a go-to for form finding and animation-driven studies; many workflows then “rationalized” its meshes into NURBS/B‑reps for documentation. Finally, CATIA V5, deployed by Gehry Technologies as Digital Project, offered high-end surface control and rigorous master-model workflows, with downstream coordination tools suited to complex cladding and aerospace-grade tolerances. Together, these tools enabled:

- Associative skeletons where curves and section families drove lofts, sweeps, and ribbons.

- Constraint networks encoding dimensional/relational rules so intent persisted across variants.

- Surface diagnostics for curvature, planarity, and Gaussian targets guiding rationalization.

- Metadata-rich exports to analysis tools and fabrication pipelines.

Parametric patterns: from drivers to fabrication and feedback

Techniques matured into reusable patterns that connected sketch to shop. Designers established associative skeletons: master curves, guide rails, and section families that drove lofts and sweeps, making hierarchy explicit. Constraint solving—dimensional, angular, and relational—preserved intent under change, enabling rapid variant studies where sliders mapped to meaningful design moves. Surface rationalization transformed freeform aspirations into buildable families: ruled or developable strips for sheet materials, triangulations for double curvature with flat facets, quad grids tuned for target curvature and planarity tolerances. Panelization to fabrication completed the chain: UV unrolling where appropriate, seam logic designed to avoid stress concentrations, indexing and nesting scripted to minimize waste, and data handoffs carrying IDs, normals, and drilling coordinates directly to CNC, mold-making, or rebar/formwork systems. Feedback loops made the system intelligent rather than merely descriptive. Curvature analysis flagged hotspots requiring thicker skins or denser substructure. Daylight and visibility studies fed back into aperture size and orientation. Structural simulations—via Arup and AKT II toolchains—returned stress contours that informed parameter ranges and discretization density. Typical patterns included:

- Master sketches whose topology aligned with circulation and MEP routing, preventing downstream clashes.

- Bidirectional links between panel families and analysis, allowing scripts to thicken or thin members based on utilization.

- Export recipes that generated both human-readable schedules and machine-ready cut files in one pass.

Canonical workflows and case notes

Zaha Hadid Architects — Phaeno Science Center (Wolfsburg, 1998–2005)

Phaeno’s complex soffits and shells demanded a workflow that merged sculptural intent with construction logic. Early exploratory modeling in Maya and Rhino captured the project’s fluid massing, but to stabilize design intent and manage change, the team established associative control lines in MicroStation/GenerativeComponents. These controllers—curves, rails, and section families—governed the ribbon-like surfaces, allowing designers to adjust key profiles while preserving continuity and intersection behavior. Rationalization became the bridge to buildability: freeform regions were decomposed into toleranced parts, with scripted patterns guiding openings and edge conditions to respect curvature thresholds. Collaboration with engineering teams—drawing on Arup’s experience with custom analysis routines—produced thickening logics tied to stress ranges, and formwork strategies aligned to feasible mold types and casting sequences. Parametric definitions indexed parts, coordinated seams to minimize rework, and produced schedules that fed directly to fabricators handling CNC templates and complex rebar cages. Critically, the GC transaction history documented the lineage of changes, allowing the team to revisit earlier states, compare options, and ensure that shape edits propagated consistently through details. The outcome was a model that did not merely describe geometry but maintained the relationships that made it constructible under the time and tolerance pressures of site.

Zaha Hadid Architects — MAXXI Museum (Rome, 1998–2009)

At MAXXI, the ribbon-like galleries and interlaced volumes were orchestrated by controlling splines and sections that encoded continuity targets—G1/G2 where appropriate—and rules for clash-free intersections. The team set up a family of “ribbons” in MicroStation and Rhino whose cross-sections produced slabs, beams, and soffits as parametric derivatives, while intersection scripts policed junctions to avoid unbuildable saddle points. Parametric re-parameterization proved decisive for construction planning: reinforcement zones, MEP pathways, and casting sequences were linked to the master curves so that a change in curvature or alignment reissued updated rebar densities, sleeve penetrations, and pour sequences. Exchanges with Arup’s structural group iterated toward simpler, more robust geometries where analysis indicated marginal gains; in many places, subtle flattening or rationalization replaced exuberant curvature to ease formwork without losing spatial intent. Panel and shutter schedules emerged from scripted generators that tagged elements with position, rotation, and casting order, while clash detection against MEP preserved the continuity of public ribbons without contortions downstream. The model functioned as a decision ledger: each relation—thickness to span, aperture to daylight factor, rib spacing to stress envelope—lived as a parameter with a range rather than a fixed number, enabling negotiation through shared data rather than redlines alone.

UNStudio — Mercedes-Benz Museum (Stuttgart, 2001–2006)

The museum’s iconic double-helix circulation exemplified UNStudio’s use of parametric families to keep a complex spatial script legible. A compact set of drivers—helix pitch, offset, radii, and floor-to-floor heights—generated slabs, cores, and balustrades from a single source-of-truth geometry. This master model propagated to 2D drawings and coordination views, ensuring that documentation tracked changes without duplication. Structural logic was folded into the same parameter set: thickness, spacing, and torsion thresholds informed by analysis scripts constrained allowable edits, so designers operated within a safe solution space. Export scripts emitted geometry and metadata for engineer-side models, where utilization data returned as color-mapped feedback and numbers the architects could act on. The result was a loop where circulation adjustments could be tested against egress, daylight, and structure within hours, not weeks. Fabrication intent followed suit: seam logics for cladding, panel sizes governed by transport and handling, and indexing and nesting routines for sheet materials were all connected to the helix drivers, keeping envelope rationalization aligned with the spatial narrative. By articulating the whole project as a set of controllable relationships, the team avoided brittle one-off solutions and maintained coherence across variants demanded by client reviews and engineering developments.

UNStudio — Arnhem Central Transfer Hall (1997–2015)

Arnhem’s “twist” element—an intricate merging of floor, wall, and roof—was tamed through a reduced set of drivers designed to maintain continuity while respecting steel plate fabrication. Heights, edge curves, and tangency conditions became the core controllers, from which the surface was regenerated as a family rather than a monolith. Surface analysis tools identified curvature zones where developability could be preserved or approximated, guiding the split between ruled, singly curved, and doubly curved segments. Panelization and plate unfolding workflows built measurable, bidirectional links between design changes and shop data: when an edge curve moved, unfolded plates reissued with correct bend lines, bevel angles, and part IDs ready for nesting. Tolerances were not afterthoughts; they were parameters embedded in the definition so that gaps for welding or allowances for thermal distortion could be dialed in. Coordination with AKT II and fabricators closed the loop: stress feedback tightened parameter ranges, and cutting-path optimizations reduced waste while preserving seam logic for assembly. In this project, as elsewhere, the core achievement was not a shape but an information architecture in which continuity, fabrication, and assembly were articulated as adjustable relationships rather than fixed drawings, allowing the team to react to site realities without breaking the model.

Conclusion

From drafting to associativity: legacies and trajectories

The shift led by ZHA and UNStudio reframed architecture as a choreography of relationships, not isolated shapes. Tools like MicroStation with GenerativeComponents, Rhino with Grasshopper, Maya, and Digital Project mattered, but their deeper contribution was cultural: they encouraged scripting, analysis feedback, and tight engineer–architect collaboration as normal practice. Techniques such as master sketches, constraint networks, and surface rationalization matured into a shared digital DNA that later infused mainstream computational design and BIM-integrated workflows. In practical terms, studios learned to narrate design in parameters—curvature targets, daylight factors, utilization ratios, planarity tolerances—making change negotiable and testable. Fabrication-awareness moved upstream, so panel sizes, seam logic, nesting efficiency, and tool access were part of early conversations rather than late crises. The legacy is not merely the now-ubiquitous visual programming canvas; it is a profession comfortable with rule-based iteration, multidisciplinary feedback loops, and models that double as contracts between intent and reality. The foundations laid in the late 1990s and 2000s continue to power contemporary parametric, generative, and performance-driven practice, enabling teams to steer complexity rather than be overwhelmed by it, and to translate vision into manufacturable, measurable, and adaptable building systems.

What endures and what evolves

As computational design spreads across scales—from furniture and facades to urban systems—the enduring lesson from this era is the value of explicit relationships that travel with the model. The best workflows still start with associative skeletons and constraints that encode purpose, then iterate through analysis and fabrication-aware detailing. What evolves is the breadth of data and the reach of automation: today’s toolchains blend multi-objective optimization, machine learning–assisted exploration, and cloud-based simulation with the very same discipline of dependency and rationalization pioneered by SmartGeometry veterans and their engineering partners. The spirit of open exchange between practice and software development persists, now through APIs, package ecosystems, and communities that treat definitions as literature. And the collaboration models forged with Arup and AKT II—fast, algorithmic, and conversational—remain a benchmark for how architects and engineers can co-author solutions. In that sense, the parametric turn was less a stylistic departure than a methodological upgrade: by insisting that geometry be intelligible to both people and machines, the field equipped itself to design under uncertainty, accelerate feedback, and land visionary forms squarely in the realm of the buildable.

Also in Design News

Cinema 4D Tip: Maintain scene scale to prevent floating‑point precision errors

November 01, 2025 2 min read

Read More

ZBrush Tip: Tailoring ZBrush UI Colors for Comfort and Clarity

November 01, 2025 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …