Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

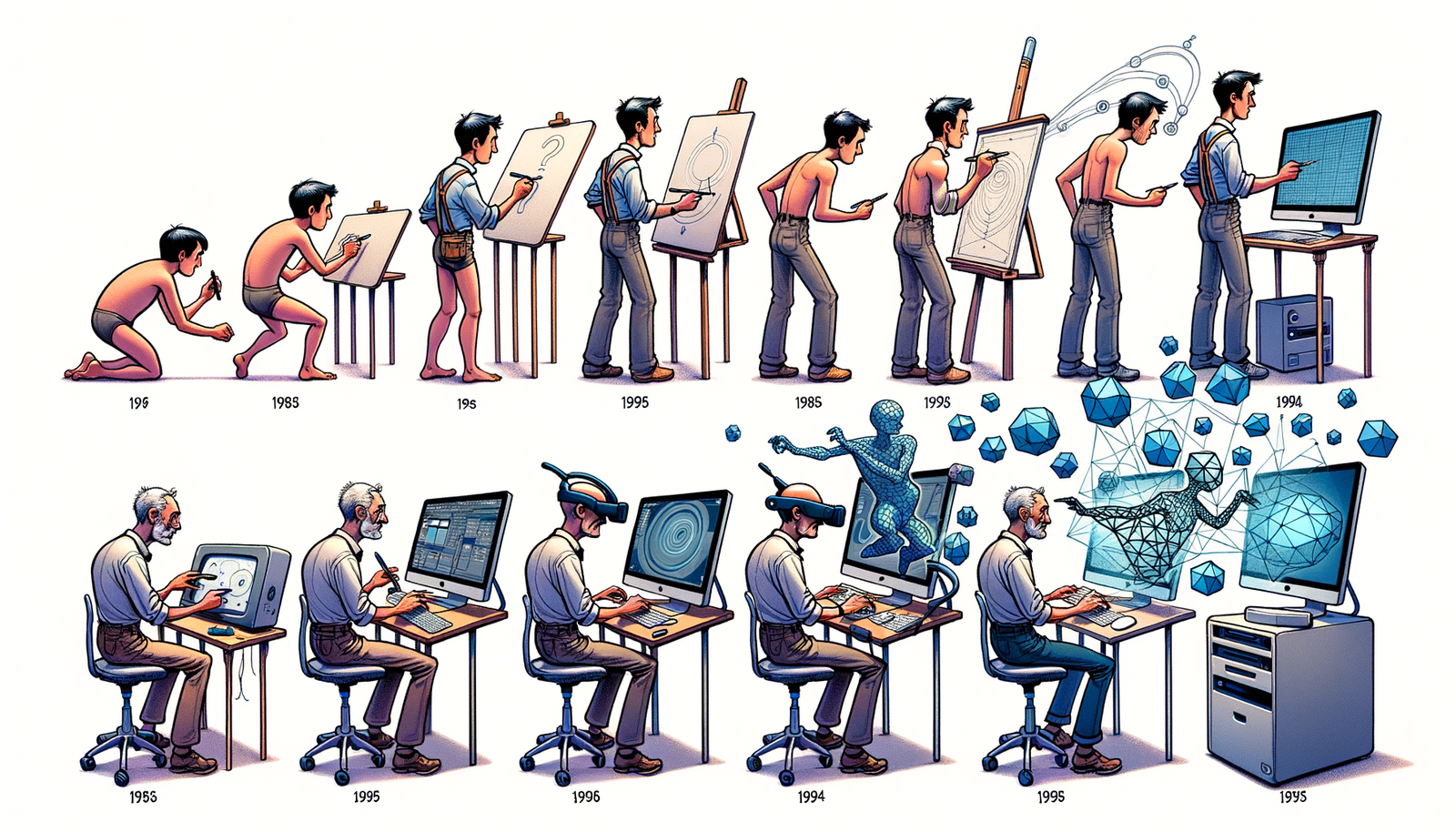

Design Software History: Foundational Challenges and Innovations in Computer-Aided Design: The Evolution of Geometric Modeling and Its Impact on Modern Design Practices

February 08, 2025 7 min read

Foundational Efforts and Early Challenges

In the nascent stages of Computer-Aided Design (CAD) during the 1960s and 1970s, engineers and designers grappled with significant obstacles in representing complex geometries. The technology of the time was limited, and the existing tools were rudimentary compared to today's sophisticated systems. One of the pivotal figures who emerged during this era was Pierre Bézier, a French engineer working for Renault. Bézier revolutionized the field by inventing the Bézier curves, a mathematical formulation that allowed for the precise control and manipulation of curves. This innovation was groundbreaking because it enabled designers to create smooth, complex shapes that were previously impossible to model accurately. Prior to this, representing and manipulating complex curves and shapes was a daunting task due to the lack of advanced mathematical models and computational power. Designers faced challenges such as:- Difficulty in accurately modeling organic and freeform shapes.

- Limited tools for modifying existing designs without extensive rework.

- Time-consuming manual calculations that hindered innovation.

Mathematical Foundations and Computational Limitations

The advancement of CAD technologies was heavily reliant on the development of robust mathematical models. The introduction of Non-Uniform Rational B-Splines (NURBS) played a crucial role in this evolution. NURBS provided a flexible and accurate method for representing complex curves and surfaces, which was essential for precise modeling in various engineering fields. However, implementing these mathematical models was met with significant challenges due to the limited computational power and memory constraints of early computers. The hardware of that era was not equipped to handle the intensive calculations required for rendering detailed geometric models. This limitation necessitated the creation of efficient algorithms in geometric computations. Researchers and mathematicians focused on optimizing computational methods to make the most of the available resources. Efforts were directed towards:- Developing approximation techniques to reduce computational load.

- Enhancing data structures for better memory management.

- Creating algorithms that could perform calculations more efficiently.

Breakthroughs in Solid Modeling

The evolution of solid modeling marked a transformative phase in the history of design software. The introduction of Constructive Solid Geometry (CSG) and Boundary Representation (B-rep) techniques provided powerful methods for representing solid objects in a virtual environment. CSG allowed designers to create complex models by combining simple geometric primitives through Boolean operations, while B-rep described solids by their boundaries, enabling detailed surface and edge definitions. Key companies like Dassault Systèmes were instrumental in advancing solid modeling technologies. Their development of CATIA (Computer-Aided Three-Dimensional Interactive Application) revolutionized the way complex shapes and assemblies were designed and managed. CATIA became a critical tool in industries such as automotive and aerospace, providing capabilities that significantly enhanced design potential. The impact on these industries included:- Facilitating the design of intricate components with greater precision.

- Improving collaboration across different engineering disciplines.

- Reducing development times through efficient modeling and simulation.

Advancements in Surface Modelling

Surface modeling advancements were critical in industries where the aesthetic and aerodynamic properties of a product were paramount. The development of sophisticated surface modeling techniques enabled designers to create smooth, flowing surfaces that enhanced both the visual appeal and functional performance of products. Software such as Alias Systems’ StudioTools (later acquired by Autodesk) became essential in fields like automotive styling and industrial design. The influence of StudioTools was profound, particularly in the automotive industry, where it facilitated the creation of complex surface geometries necessary for modern vehicle designs. Designers like Daniel G. Hillman contributed significantly to this field through their work on sculptured surface design. Hillman's research focused on improving the mathematical foundations of surface modeling, addressing challenges such as surface continuity and smoothness. Advancements in surface modeling provided several benefits:- Enabled the creation of complex and aerodynamically efficient shapes.

- Improved the integration of design and engineering processes.

- Allowed for rapid iteration and refinement of product aesthetics.

Additive Manufacturing: Expanding Design Possibilities

The integration of Additive Manufacturing (AM), commonly known as 3D printing, with CAD technologies opened new frontiers in design and manufacturing. AM allowed for the physical realization of complex, non-traditional geometries that were difficult or impossible to produce using conventional manufacturing methods. This technology expanded design possibilities by eliminating many of the constraints associated with subtractive manufacturing processes. Key software companies like Autodesk played a significant role in facilitating this integration. Autodesk's software solutions provided tools for designers to create intricate models optimized for additive manufacturing. The impact of AM on design was substantial:- Enabled the production of complex internal structures, such as lattices and honeycombs.

- Facilitated rapid prototyping, reducing time from concept to physical model.

- Allowed for customization and personalization of products at scale.

Evolving Computational Techniques

As the complexity of designs increased, so did the need for more advanced computational techniques. Parametric design emerged as a powerful approach, allowing designers to define models based on a set of parameters and relationships. This method made it easier to modify designs systematically and explore different configurations. Generative design, propelled by advances in computational power, took this concept further by using algorithms to generate optimized design solutions based on specific criteria. The role of simulation tools became more prominent in handling geometric complexity. These tools enabled designers to test and validate their models under various conditions, ensuring that they met performance requirements. Advancements in hardware, such as multi-core processors and enhanced graphics capabilities, supported these computationally intensive tasks. Evolving computational techniques brought several advantages:- Improved ability to optimize designs for weight, strength, and material usage.

- Enhanced efficiency in handling complex calculations and data processing.

- Enabled more informed decision-making through accurate predictive modeling.

Impact on Modern Design Practices

The culmination of early struggles and innovations in handling complex geometries has profoundly impacted modern design practices. Today's design software is built upon the mathematical models and computational techniques developed by pioneers in the field. The ability to accurately represent and manipulate complex geometries is now a fundamental expectation, enabling a level of sophistication in design that was previously unattainable. Early innovators like Pierre Bézier, companies such as Dassault Systèmes, and contributors like Daniel G. Hillman played crucial roles in shaping the tools and methodologies used today. Their work laid the groundwork for advancements in various design fields, including automotive, aerospace, consumer products, and architecture. The impact on modern design practices includes:- Streamlined workflows that integrate design, analysis, and manufacturing.

- Enhanced collaboration through interoperable software platforms.

- Greater innovation driven by powerful visualization and simulation tools.

Future Trends and Ongoing Challenges

As we look to the future, the integration of Artificial Intelligence (AI) and machine learning presents exciting opportunities for further advancements in geometric modeling. AI has the potential to automate complex tasks, optimize designs beyond human capability, and provide insights through data analysis. Machine learning algorithms can learn from vast amounts of data to predict outcomes and suggest improvements, enhancing the efficiency and effectiveness of the design process. However, these developments also bring ongoing challenges:- Managing the increased complexity of designs generated by AI algorithms.

- Ensuring that AI tools are transparent and that designers understand how decisions are made.

- Addressing ethical considerations related to data usage and algorithmic bias.

Also in Design News

Rhino 3D Tip: GPU Optimization for Rhino Render (Cycles), V-Ray, and Real‑Time Plugins

January 01, 2026 2 min read

Read More

Cinema 4D Tip: Efficient Lookdev Iteration Using Cinema 4D Picture Viewer History

January 01, 2026 2 min read

Read More

Revit Tip: Standardized Revit Export for Reliable Navisworks Clash Detection

January 01, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …