Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Design Software History: Evolution and Impact of Autodesk Plant 3D in Process Plant Design

September 04, 2024 4 min read

Introduction to Plant 3D

Overview of Plant 3D

Plant 3D, a pivotal software in the realm of process plant design, has revolutionized the industry with its comprehensive suite of tools tailored for the intricate demands of this sector. Developed by Autodesk, Plant 3D serves as an indispensable tool for engineers and designers focused on creating detailed and efficient plant layouts. It plays a crucial role in enhancing productivity, ensuring accuracy, and facilitating seamless collaboration across various project stakeholders.

Historical Context

Before the advent of digital tools, process plant design was a laborious task, heavily reliant on manual drafting and physical models. This period was marked by significant challenges, including lengthy design cycles, higher susceptibility to errors, and limited flexibility in making changes. The transition to Computer-Aided Design (CAD) tools marked a significant evolution, leading to more efficient and error-free design processes. However, the initial CAD solutions were general-purpose and lacked the specialized features needed for process plant design.

Development and Evolution

Origins and Early Development

The introduction of Plant 3D by Autodesk marked a significant milestone in the history of process plant design software. The development was spearheaded by a dedicated team of engineers and designers who recognized the need for a specialized tool tailored to the unique requirements of plant design. Key figures in this development include visionaries like John Walker and Dan Drake, whose leadership and expertise were instrumental in bringing Plant 3D to life.

Technological Advancements

Since its inception, Plant 3D has undergone numerous technological advancements, continually evolving to meet the changing needs of the industry. Some of the important milestones in its evolution include:

- The integration of advanced 3D modeling capabilities

- The development of specialized tools for piping and instrumentation diagram (P&ID) creation

- The introduction of cloud-based features and collaboration tools

These advancements have significantly enhanced the software's functionality, making it a powerful tool for modern plant design.

Key Versions and Updates

Over the years, Autodesk has released several major updates to Plant 3D, each bringing new features and improvements that enhance usability and functionality. Notable updates include:

- The introduction of intelligent P&ID tools for faster and more accurate design

- Enhanced 3D modeling capabilities for more detailed and complex plant layouts

- Cloud-based collaboration features that allow for real-time project collaboration

These updates have played a crucial role in establishing Plant 3D as a leading tool in the industry, continually pushing the boundaries of what is possible in process plant design.

Core Technologies and Features

Geometric and Solid Modeling

At the heart of Plant 3D lies its robust geometric and solid modeling capabilities. The software leverages advanced mathematical models and algorithms to create accurate 3D representations of plant components. These models are essential for visualizing complex plant layouts, ensuring that all components fit together seamlessly, and identifying potential issues early in the design process. Plant 3D's solid modeling capabilities are specifically tailored to the needs of process plant design, making it a powerful tool for creating detailed and accurate plant layouts.

Process and Piping Design

One of the standout features of Plant 3D is its specialized tools for process and piping design. The software includes a comprehensive set of tools for creating piping and instrumentation diagrams (P&ID), which are essential for planning and documenting the layout of piping systems. These tools allow designers to create detailed and accurate diagrams quickly and easily, enhancing productivity and ensuring consistency across projects. Additionally, Plant 3D includes features for efficient layout and modification of piping systems, making it easier to make changes and updates as needed.

Integration with Other Software

Plant 3D is designed to work seamlessly with other Autodesk products and third-party software, facilitating smooth data exchange and collaboration. This compatibility is particularly important in the context of Building Information Modeling (BIM) workflows, where data interoperability is crucial. By integrating with other software, Plant 3D enables designers to leverage a wide range of tools and resources, enhancing the overall efficiency and effectiveness of the design process.

Impact and Future Trends

Industry Adoption and Case Studies

Plant 3D has been widely adopted across various industries, with many prominent projects and companies utilizing the software for their process plant design needs. Its impact on project efficiency and accuracy is well-documented, with numerous case studies highlighting the benefits of using Plant 3D for complex plant design projects. The software's ability to streamline the design process, reduce errors, and facilitate collaboration has made it an essential tool for modern plant design.

Challenges and Limitations

Despite its many advantages, Plant 3D is not without its challenges and limitations. Some of the current limitations include:

- Complexity of the software, which can make it difficult for new users to learn and use effectively

- Performance issues when working with very large and complex models

- Limited functionality for certain specialized design tasks

Feedback from industry professionals highlights these areas for improvement, suggesting that future updates should focus on addressing these limitations to further enhance the software's usability and functionality.

Future Trends

The future of process plant design is shaped by emerging trends in technology, and Plant 3D is evolving to meet these future needs. Some of the potential advancements include:

- Integration of AI and machine learning to automate routine design tasks and enhance decision-making

- Advancements in automation to further streamline the design process

- Enhanced cloud-based features for improved collaboration and data management

These trends are poised to transform the industry, and Plant 3D is at the forefront of this evolution, continually adapting to leverage new technologies and meet the changing demands of process plant design.

Also in Design News

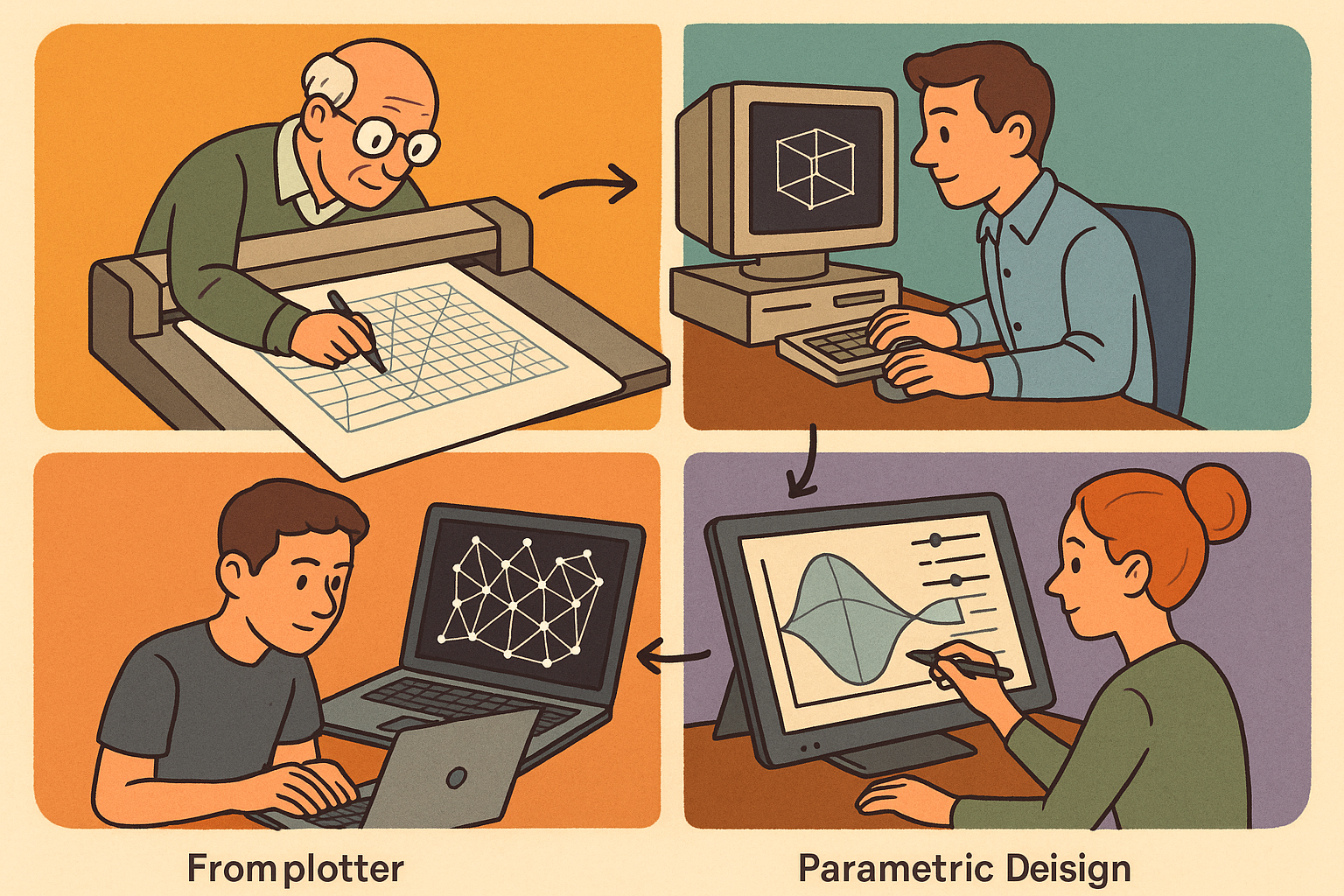

Design Software History: From Plotters to Procedural Intent: A Technical History of Generative and Parametric Design Software

January 04, 2026 13 min read

Read More

Semantic Meshes: Enabling Analytics-Ready Geometry for Digital Twins

January 04, 2026 12 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …