Your Cart is Empty

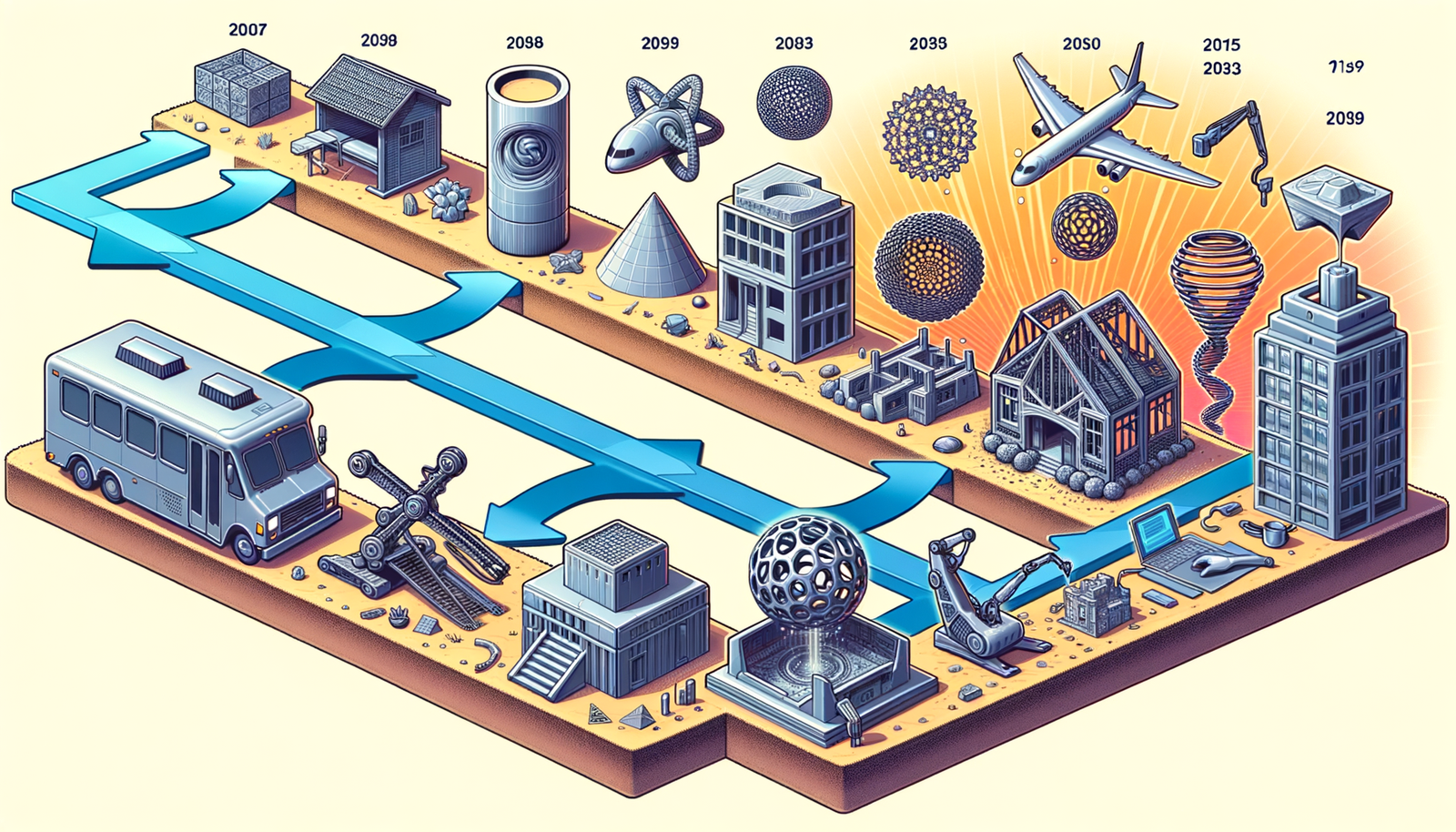

Origins and Early Developments

Introduction to Additive Manufacturing

Additive manufacturing (AM), commonly known as 3D printing, represents a transformative approach to creating objects. Unlike traditional subtractive manufacturing, which involves cutting away material from a solid block, AM builds objects layer by layer from digital models. This fundamental shift allows for unprecedented design flexibility, complexity, and customization.

The initial impetus for design software tailored for AM emerged from the need to efficiently translate digital models into physical objects. Early AM technologies, such as Stereolithography (SLA) and Selective Laser Sintering (SLS), required precise control over the additive process, necessitating specialized software.

Pioneering Software and Companies

The early days of AM saw adaptations of existing Computer-Aided Design (CAD) software to meet the unique requirements of layer-based manufacturing. A pivotal figure in this era was Charles Hull, who not only invented the concept of SLA but also co-founded 3D Systems in 1986 to commercialize it. His work laid the foundation for the development of the Standard Tessellation Language (STL) file format, which became a cornerstone for 3D printing. The STL format simplified the process of turning CAD models into printable objects by representing 3D surfaces as a series of interconnected triangles.

Technological Foundations

The technological underpinnings of AM are rooted in techniques like Stereolithography (SLA), developed by Charles Hull, and Selective Laser Sintering (SLS), pioneered by Dr. Carl Deckard. SLA uses a laser to cure liquid resin into solid form, layer by layer, while SLS employs a laser to fuse powdered material. These processes required software capable of handling complex geometries and precise control over layer deposition.

Initial software requirements for these technologies included the ability to slice 3D models into thin layers, generate support structures for overhanging parts, and ensure proper adhesion between layers. The constraints of early AM software were significant, as they had to balance computational efficiency with the accuracy and resolution needed to produce high-quality prints.

The Rise of Specialized Design Tools

Transition from General CAD to AM-Specific Software

The limitations of traditional CAD software in addressing the unique challenges of AM led to the development of specialized design tools. Traditional CAD systems were primarily designed for subtractive manufacturing and often struggled with the intricacies of layer-based fabrication. This gap paved the way for software tailored specifically to the needs of AM processes.

Specialized design tools introduced capabilities such as automatic support generation, mesh repair functionalities, and optimization for printability. These advancements significantly improved the efficiency and quality of 3D-printed objects, making AM more accessible and reliable for a wide range of applications.

Key Software Developments

Several software solutions emerged to address the specific needs of AM. Notably, Autodesk Netfabb and Materialise Magics became industry standards for their robust features. Autodesk Netfabb offered advanced tools for STL file repair, support generation, and build preparation, while Materialise Magics excelled in mesh repair, part orientation, and support structure optimization.

These software packages introduced innovations that enhanced the capabilities of AM, such as:

- Support Generation: Automatic creation of support structures to stabilize overhanging sections during printing.

- Mesh Repair: Tools to fix common issues in 3D models, such as holes, intersecting triangles, and non-manifold edges.

- Build Preparation: Features to optimize part orientation, nesting, and slicing for efficient and accurate printing.

Influential Companies and Individuals

The evolution of software for AM was driven by key companies and individuals who made significant contributions to the field. Stratasys and EOS were instrumental in advancing AM technologies and developing corresponding software solutions. Stratasys, co-founded by Scott Crump, introduced Fused Deposition Modeling (FDM) and developed software that optimized the printing process for this technology.

EOS, a leader in SLS technology, also made substantial advancements in software for powder-based AM. Their software offerings included tools for part orientation, support generation, and process parameter optimization, enabling users to achieve high-quality prints with minimal material waste.

Advanced Modeling Techniques and Integration

Evolution of Geometric and Solid Modeling

As AM technologies matured, so did the modeling techniques used to create complex geometries. Advanced modeling techniques, such as lattice structures and topology optimization, became increasingly important for maximizing the benefits of AM. Lattice structures, for instance, allowed for lightweight yet robust designs, while topology optimization enabled the creation of parts with optimized strength-to-weight ratios.

The incorporation of Non-Uniform Rational B-Splines (NURBS) and parametric modeling further enhanced the capabilities of AM software. NURBS allowed for the creation of smooth, freeform surfaces, while parametric modeling enabled designers to easily modify and optimize their designs based on specific parameters and constraints.

Integration with Other Technologies

The integration of AM software with other technologies, such as simulation tools and Finite Element Analysis (FEA), played a crucial role in refining designs for additive manufacturing. Simulation tools allowed designers to predict and analyze the behavior of printed parts under various conditions, such as stress, thermal properties, and deformation. This integration helped identify potential issues early in the design process, reducing the need for costly and time-consuming prototypes.

FEA, in particular, became an indispensable tool for validating and optimizing designs for AM. By simulating the mechanical performance of parts, FEA helped ensure that printed objects would meet the required specifications and perform reliably in real-world applications.

Collaborative Platforms and Cloud Computing

The emergence of cloud-based design platforms, such as Autodesk Fusion 360, revolutionized the way designers and engineers collaborated on AM projects. These platforms facilitated real-time collaboration, allowing multiple users to work on the same design simultaneously and share updates instantly. Cloud computing also enabled more efficient management of design data and resources, streamlining the iterative design process.

Cloud-based design platforms offered several benefits, including:

- Enhanced Collaboration: Real-time collaboration tools that enabled seamless communication and coordination among team members.

- Scalable Resources: Access to powerful cloud-based computing resources for complex simulations and design tasks.

- Data Management: Centralized storage and management of design data, ensuring version control and data integrity.

Future Trends and Innovations

Impact of AI and Machine Learning

The integration of artificial intelligence (AI) and machine learning (ML) into AM software is poised to revolutionize the design process. Predictive modeling and generative design are two areas where AI is making a significant impact. Predictive modeling uses AI algorithms to forecast the performance and behavior of printed parts, helping designers make informed decisions and optimize their designs.

Generative design, powered by AI, takes design optimization to a new level. By specifying design goals and constraints, designers can leverage AI to generate multiple design iterations that meet the specified criteria. This approach allows for the exploration of a broader design space and the identification of innovative solutions that may not have been considered through traditional design methods. Examples of AI-driven design platforms include nTopology and Autodesk’s generative design tools.

Customizable, User-Friendly Interfaces

The development of more intuitive and user-friendly design interfaces is making AM software accessible to a broader audience. As the demand for AM grows, software developers are focusing on creating interfaces that cater to both novice and experienced users. This includes customizable interfaces that allow users to tailor the software to their specific needs and preferences.

User feedback plays a crucial role in the evolution of these interfaces. By incorporating feedback from a diverse user base, software developers can identify areas for improvement and introduce features that enhance the user experience. The goal is to create design software that is not only powerful but also easy to use, enabling more people to harness the potential of additive manufacturing.

Future Directions and Challenges

As AM software continues to evolve, several challenges and future directions are shaping its development. One ongoing challenge is the issue of interoperability. With a wide variety of AM technologies and software solutions available, ensuring seamless communication and data exchange between different systems remains a critical goal. Standards and protocols for interoperability are essential for streamlining the AM workflow and reducing barriers to adoption.

Scalability is another key challenge. As AM moves from prototyping to full-scale production, software must be capable of handling larger datasets and more complex designs efficiently. This requires advancements in computational power, data management, and optimization algorithms.

Future trends in AM software include real-time monitoring and the integration of digital twins and the Internet of Things (IoT). Real-time monitoring involves the continuous observation of the AM process to detect and address issues as they arise, ensuring higher quality and consistency in printed parts. Digital twins, which are virtual replicas of physical objects, enable real-time simulations and analysis, enhancing the design and manufacturing process. IoT integration allows for the seamless connection of AM machines and systems, facilitating data exchange and process automation.

Conclusion

The history of design software for additive manufacturing is a testament to the continuous evolution and innovation in the field. From the early days of adapting traditional CAD software to the rise of specialized design tools and advanced modeling techniques, AM software has come a long way. The integration of AI, cloud computing, and collaborative platforms is driving the future of AM, making it more accessible and efficient.

As we look to the future, the ongoing advancements in AM software hold the potential to revolutionize various industries, from aerospace and automotive to healthcare and consumer products. The ability to create complex, customized, and high-performance parts with ease will continue to drive innovation and redefine the possibilities of design and manufacturing.