Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Autodesk signs definitive agreement to acquire FlexSim

October 23, 2023 4 min read

From Autodesk News: Stephen Hooper

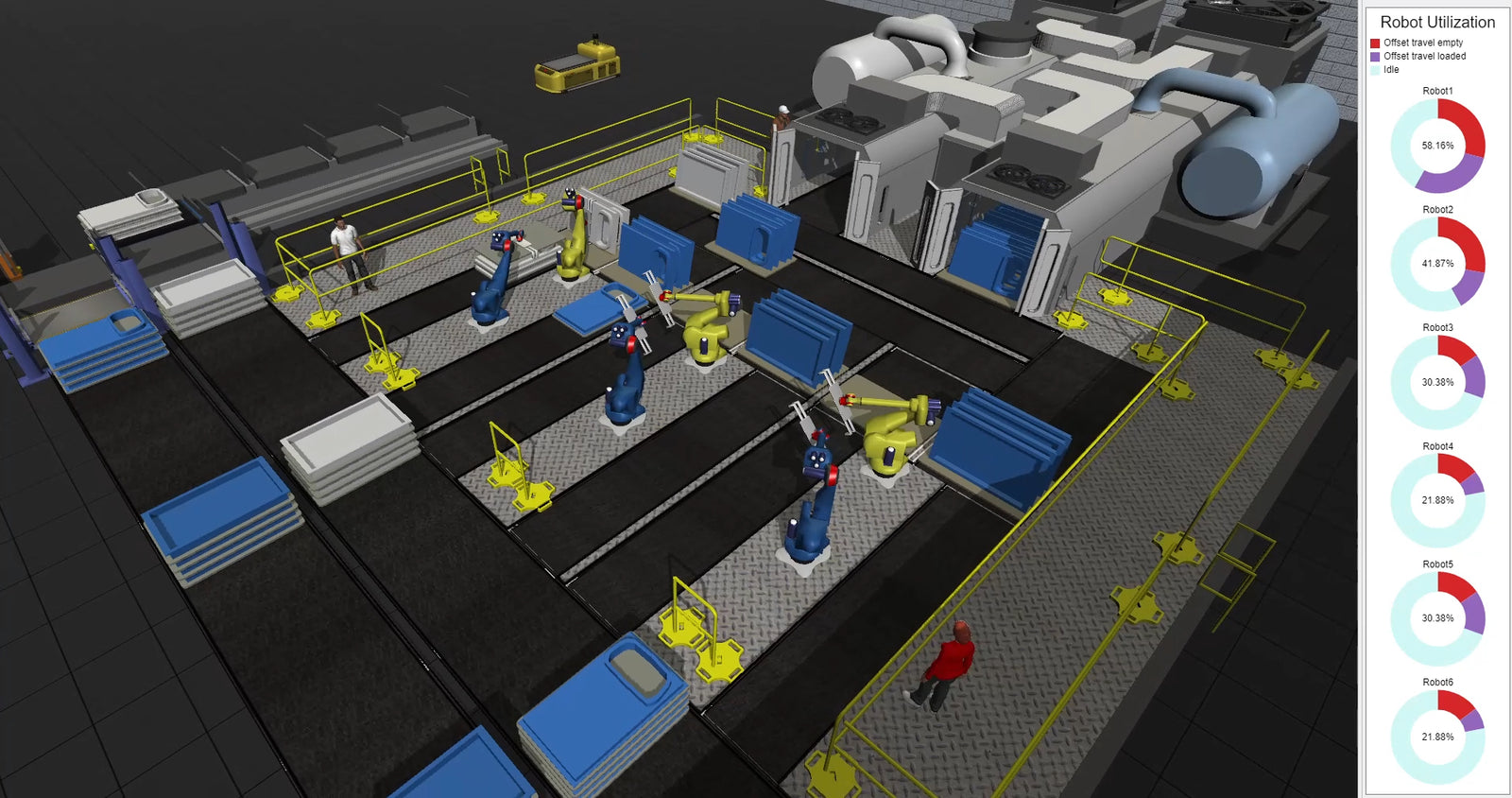

FlexSim’s technology simulates the operation of a factory floor or logistics center, providing production flow analysis and performance metrics while bringing it to life.

Autodesk to add factory simulation and operational efficiency analysis to its factory design tools when acquisition completes

It’s a volatile time for manufacturers. Energy and material costs continue to increase. Climate concerns have governments across the globe regulating more. Nearshoring and onshoring of production are a top priority. Those are more than enough reasons to make optimizing operations and logistics a must for manufacturers. And doing that will require the digital transformation of factories.

In a big step toward addressing this critical need, I’m excited to announce that Autodesk has signed a definitive agreement to acquire FlexSim, a provider of simulation technology that enables factory and logistics center operators to optimize their processes. Through discrete event simulation, or DES, FlexSim’s technology brings the design of a factory or logistics center to life. It puts production flow analysis at the fingertips of operations leaders to surface fundamental business insights that help achieve time and cost objectives.

FlexSim’s factory simulation technology complements Autodesk’s existing factory design solutions. It provides in-depth model analysis, layout scenarios, and process simulation to users of Autodesk Inventor, Revit, Autodesk Construction Cloud, AutoCAD, and Autodesk’s Product Design and Manufacturing Collection. FlexSim will initially be offered in conjunction with Autodesk’s Design and Make Platform, closely aligned with Autodesk Fusion, which integrates CAD, PCB design, CAM, CAE, PLM, and MES software into a single, cloud-based solution.

In addition to enabling easy creation of a factory simulation, FlexSim’s technology can be the engine that powers a key link between factory design data and operational data. Think of how powerful that will be for an asset’s digital twin. Imagine a greenfield or brownfield factory layout seamlessly maturing into a high-resolution model of the factory, and from there into a digital virtual replica of the factory.

Simulation powers superior insights and processes

A digital representation of a factory is an environment where you can plan, simulate, and control operations to accurately predict performance, forecast energy consumption and emissions, analyze safety, and measure equipment utilization. FlexSim brings all these capabilities, enabling more informed decisions sooner, helping meet production targets with precision, and reducing time to market and costly inventory.

Simulation is foundational to a digital factory. By its nature, simulation uncovers the need for changes—in design, workflows, and products. No one wants to bolt a $4 million machine to the floor only to move it soon thereafter, along with everything else, due to poor planning. If a simulation uncovers a problem requiring a change like that, the change must be captured, quickly and efficiently communicated to every stakeholder, and archived. Today, those types of changes get trapped in data silos and files, or lost in email threads, increasing the likelihood of costly mistakes and delays because a change instruction didn’t reach everyone who needed to know.

With FlexSim’s capabilities, factory and logistics center planners can better understand the downstream effects and unintended consequences of changes in a production facility and more accurately predict operational performance. And that can happen before costly long-term capital asset decisions are set in stone. That’s good for the bottom line and enables businesses to scale efficiently in an increasingly uncertain world.

FlexSim adds new layer to centralized and connected data

To have reliable simulations, manufacturers need reliable data—data that’s secure and available anywhere, at any time, to the people who should have access. These are guiding principles of the Autodesk Design and Make Platform, which is enabled by cloud-connected data. In this environment, design data flows to everyone in the product lifecycle, from CAD through to CAM and into the manufacturing execution system, or MES. By acquiring FlexSim, we’re investing in extending this environment to also include factory simulation.

Centralized and connected data breaks down silos. FlexSim’s capabilities build simulation insights on top of existing facility layout and planning data. These insights can complement our Factory Design Utilities and conclusively demonstrate our aggressive moves toward delivering the full value of cloud-first software.

In a connected environment, there’s no data loss or miscommunication. Whatever decisions are made based on the simulation are maintained in a single digital thread and shared with all stakeholders. This enables everyone to learn from each cycle, process, and product, improving the results of the next iteration.

Subject to the completion of the acquisition, by joining Autodesk, FlexSim will bring us crucial factory design capabilities, increasing our ability to help our manufacturing customers design and make a better world for all.

Autodesk’s acquisition of FlexSim has not been completed; the completion of the acquisition is uncertain and is subject to various closing conditions. Subject to the timely completion or waiver of the applicable closing conditions, Autodesk expects the acquisition to close either during Autodesk’s fourth quarter of Fiscal Year 2024, ending January 31, 2024, or during Autodesk’s first quarter of Fiscal Year 2025, ending April 30, 2024. It will have no material impact on Autodesk’s fourth quarter and fiscal year 2024 guidance presented on August 23, 2023. The foregoing descriptions of the contemplated effects of the acquisition are subject to the acquisition’s completion and Autodesk’s ability to successfully integrate FlexSim in all respects.

This communication may make statements regarding future events and development efforts for our products and services. These statements reflect our current expectations based on what we know today. Our plans are not intended to be a promise or guarantee of future delivery of products, services, or features, and purchasing decisions should not be made based upon these statements. We do not assume any responsibility to update this communication to reflect events that occur or circumstances that exist after the publish date of this communication.

Browse Autodesk Products

The world's leading innovator of 2D and 3D graphics technology

Also in Design News

Cinema 4D Tip: Weight Painting Best Practices for Clean Joint Deformations in Cinema 4D

February 08, 2026 2 min read

Read More

V-Ray Tip: Remote Rendering Preflight & Submission Best Practices

February 08, 2026 2 min read

Read More

Revit Tip: Transfer Project Standards into an Active Revit Model

February 08, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …