Your Cart is Empty

Customer Testimonials

-

"Great customer service. The folks at Novedge were super helpful in navigating a somewhat complicated order including software upgrades and serial numbers in various stages of inactivity. They were friendly and helpful throughout the process.."

Ruben Ruckmark

"Quick & very helpful. We have been using Novedge for years and are very happy with their quick service when we need to make a purchase and excellent support resolving any issues."

Will Woodson

"Scott is the best. He reminds me about subscriptions dates, guides me in the correct direction for updates. He always responds promptly to me. He is literally the reason I continue to work with Novedge and will do so in the future."

Edward Mchugh

"Calvin Lok is “the man”. After my purchase of Sketchup 2021, he called me and provided step-by-step instructions to ease me through difficulties I was having with the setup of my new software."

Mike Borzage

Advancing Product Development: The Power of Modular Design in Modern Industries

August 24, 2024 4 min read

Introduction to Modular Design

Definition and Concept

Modular design refers to an approach in product development where a system is divided into smaller parts or modules that can be independently created and then used in different systems. These modules are designed to fit together in multiple configurations, enhancing the flexibility and adaptability of the product.

The principles of modular design include standardization, interchangeability, and reusability. Historically, modular design has evolved from early industrial practices where simplicity and ease of assembly were critical, to modern applications where the emphasis is on customization and rapid scalability.

Importance in Modern Product Development

In today's rapidly changing market, modular design has grown in significance across various industries. Its relevance is driven by the need for flexibility, scalability, and efficiency. Companies are increasingly adopting modular design to stay competitive and meet consumer demands for personalized and upgradable products.

Key benefits of modular design include:

- **Flexibility**: Ability to create multiple product variations from a set of standard modules.

- **Scalability**: Easier to scale production up or down based on demand.

- **Efficiency**: Reduction in time and cost associated with product development and manufacturing.

Advantages of Modular Design

Cost Efficiency

One of the primary advantages of modular design is its potential for significant cost savings in both development and production. By reusing modules across different products, companies can reduce the need for new designs and tooling, thereby lowering overall costs.

For example, in the electronics industry, leveraging standardized modules can result in substantial savings by avoiding the need to redesign common components for each new product iteration.

Time-to-Market

Modular design accelerates the development process by enabling faster prototyping and iteration cycles. With modular components, engineers can quickly assemble and test new configurations without starting from scratch.

The modular approach also streamlines assembly processes, reducing complexity and time required to bring a product to market. This is particularly beneficial in industries where speed and agility are critical competitive advantages.

Customization and Upgradeability

Modular design enhances a company's ability to customize products to meet specific customer needs. Because modules can be easily swapped or upgraded, products can be tailored to individual preferences without extensive redesign.

This flexibility extends to post-purchase scenarios as well, where customers can upgrade their products by replacing or adding new modules. This simplifies maintenance and extends the product's lifecycle, providing a better return on investment for both manufacturers and consumers.

Sustainability

Modular design contributes to sustainability by reducing waste and promoting the reuse of components. Instead of discarding entire products, individual modules can be refurbished or replaced, minimizing the environmental impact.

The emphasis on modularity also encourages eco-friendly design practices, as companies are incentivized to create durable, long-lasting modules that can be used across multiple product generations.

Modular Design in Practice

Industry Applications

Modular design is applied across a wide range of industries, each leveraging its benefits to enhance product development and customer satisfaction.

- Consumer Electronics: Modular smartphones and laptops allow users to upgrade individual components such as batteries, cameras, and memory, extending the device's lifespan.

- Automotive: Modular vehicle platforms enable manufacturers to produce different models using shared components, reducing production costs and increasing flexibility.

- Architecture: Modular buildings and prefabricated structures allow for faster construction times and scalable designs, making it easier to adapt to changing requirements and site conditions.

Software Tools and Techniques

Effective implementation of modular design relies on advanced software tools and techniques. Computer-Aided Design (CAD) software plays a crucial role by supporting the creation and manipulation of modular components.

Integration with Product Lifecycle Management (PLM) systems ensures efficient management of modules throughout the product's lifecycle, from design to production and maintenance. Additionally, simulation and validation tools are essential for testing and optimizing modular assemblies, ensuring that they meet performance and safety standards.

Challenges and Future Directions

Challenges in Implementation

While the benefits of modular design are substantial, there are also challenges associated with its implementation. Standardization and compatibility issues can arise, particularly when integrating modules from different suppliers or designing for diverse markets.

Managing the complexity of modular configurations requires robust planning and coordination to ensure that all components work seamlessly together. This can be particularly challenging in large-scale projects or industries with stringent regulatory requirements.

Future Trends

The future of modular design is promising, with several emerging trends poised to enhance its impact on product development. Advances in artificial intelligence (AI) and machine learning are enabling more sophisticated optimization of modular designs, improving efficiency and performance.

The advent of new technologies such as the Internet of Things (IoT) and 5G connectivity is also influencing modular product development. These technologies facilitate smarter, more connected modules that can communicate and collaborate in real-time, offering new possibilities for innovation.

Additionally, increased automation in modular assembly processes is expected to further reduce costs and improve production speed, making modular design even more attractive to manufacturers.

Conclusion

In conclusion, the benefits of modular design in product development are numerous and compelling. From cost savings and faster time-to-market to enhanced customization and sustainability, modular design offers a robust framework for creating flexible, scalable, and efficient products.

As industries continue to embrace modular design principles, the potential for innovation and improvement will only grow. Companies are encouraged to integrate modular design into their product development strategies, leveraging its advantages to stay competitive in a rapidly evolving market.

Also in Design News

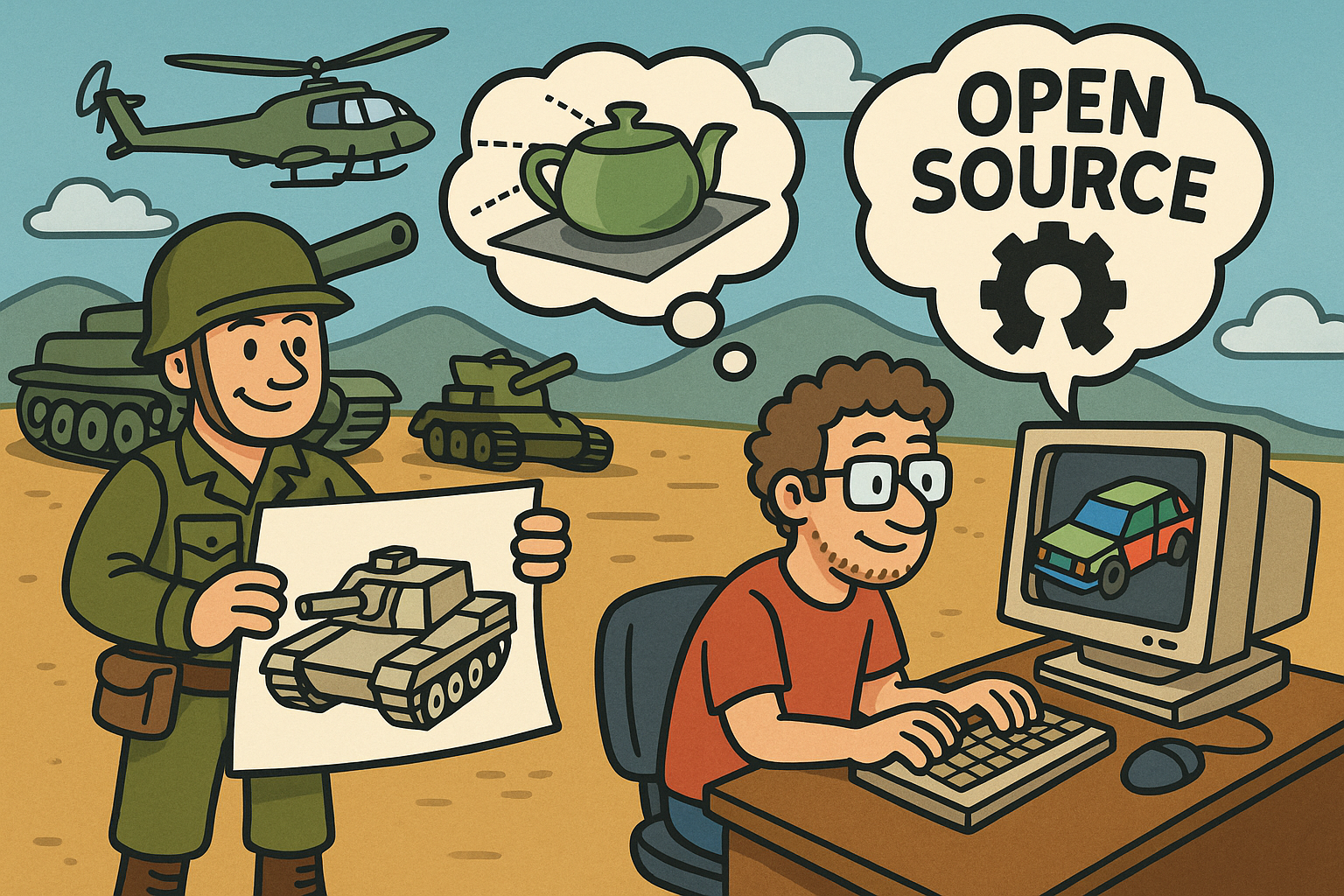

Design Software History: BRL-CAD: Military Roots to Open-Source CSG and Deterministic Ray-Tracing for Simulation

March 07, 2026 13 min read

Read More

Continuous Integration for Design: Operationalizing DesignOps for CAD, CAE, and Documentation

March 07, 2026 16 min read

Read More

Cinema 4D Tip: Cinema 4D Light Baking Workflow and Best Practices

March 07, 2026 2 min read

Read MoreSubscribe

Sign up to get the latest on sales, new releases and more …